Optical imaging lens

An optical imaging lens and imaging technology, applied in optics, optical components, instruments, etc., can solve problems such as picture resolution or discontinuity of field of view, and the arrangement of multiple lenses takes up space, and achieve good optical performance, small size, and small size. The effect of the aperture value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

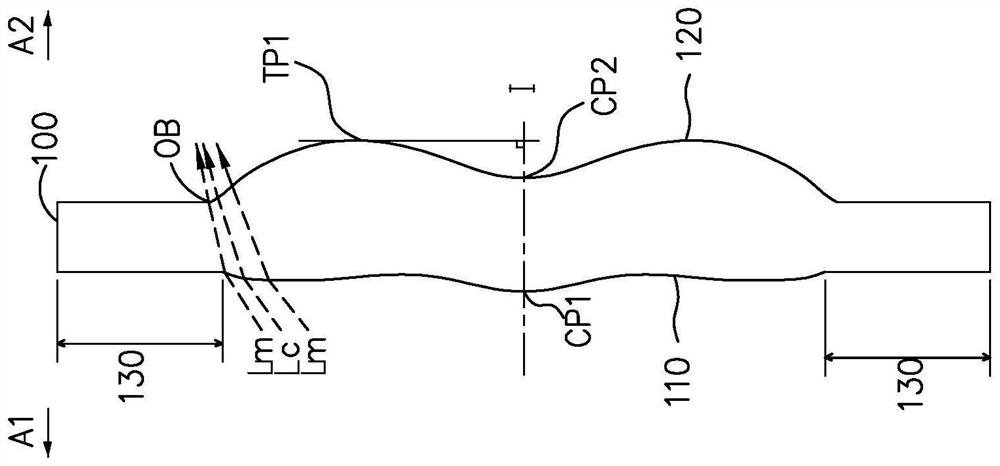

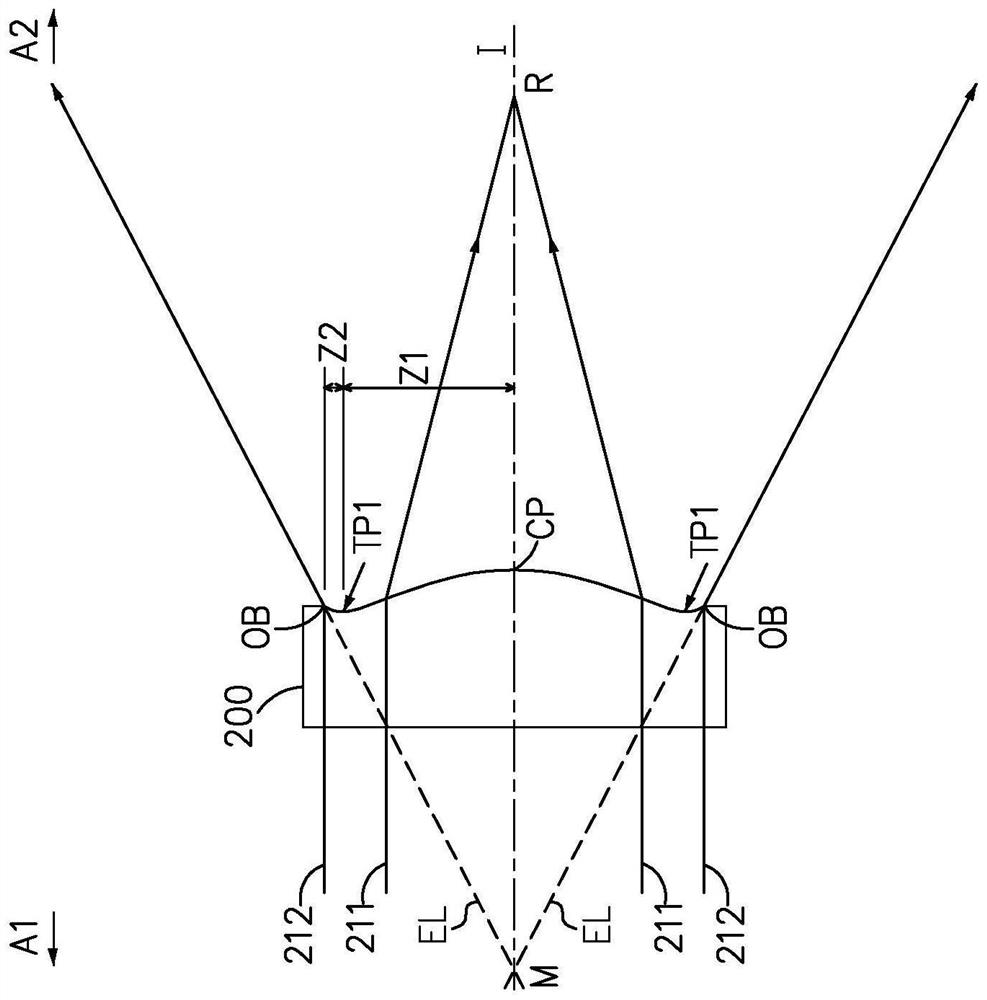

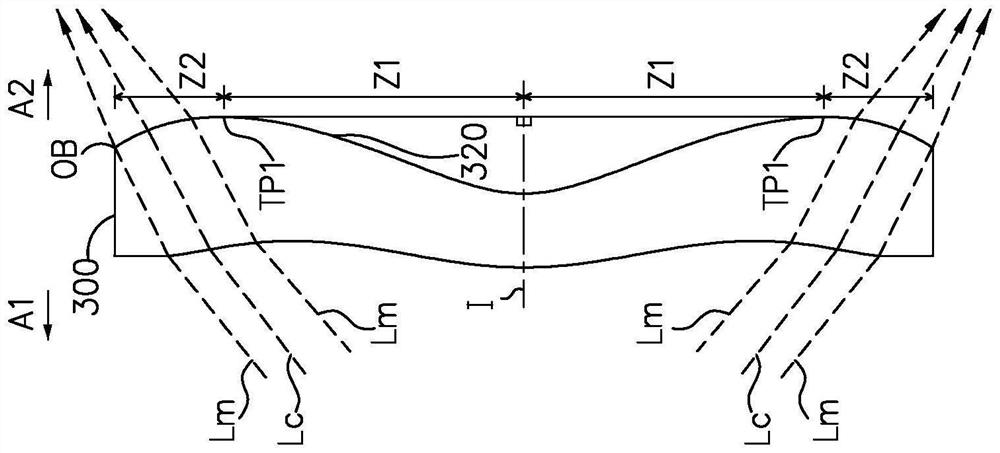

[0050] Before starting to describe the present invention in detail, first clearly indicate the symbols in the drawings: 0: aperture; 1: first lens; 2: second lens; 3: third lens; 4: fourth lens; 5: fifth Lens; 6: sixth lens; 7: seventh lens; 9: optical filter; 10: optical imaging lens; 15, 25, 35, 45, 55, 65, 75, 95, 110, 410, 510: object side ;16, 26, 36, 46, 56, 66, 76, 96, 120, 320: image side; 99: imaging surface; 100, 200, 300, 400, 500: lens; 130: assembly part; 251, 261, 351, 361, 451, 461, 551, 561, 651, 661, 751, 761, Z1: optical axis area; 153, 163, 253, 263, 353, 363, 453, 463, 553, 563, 653, 663, 753, 763, Z2: circumferential area; 211, 212: parallel rays; A1: object side; A2: image side; D1, D2, D3: adjustable air gap; CP: center point; CP1: second 1 center point; CP2: second center point; EL: extension line; I: optical axis; Lc: chief ray; Lm: marginal ray; M, R: intersection point; OB: optical boundary; TP1: first transformation point; TP2: second transition p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com