Visual sorting system and control method thereof

A sorting system and control method technology, applied in sorting and other directions, can solve the problems affecting the efficiency of upstream workpiece sorting, low sorting efficiency, and high labor costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

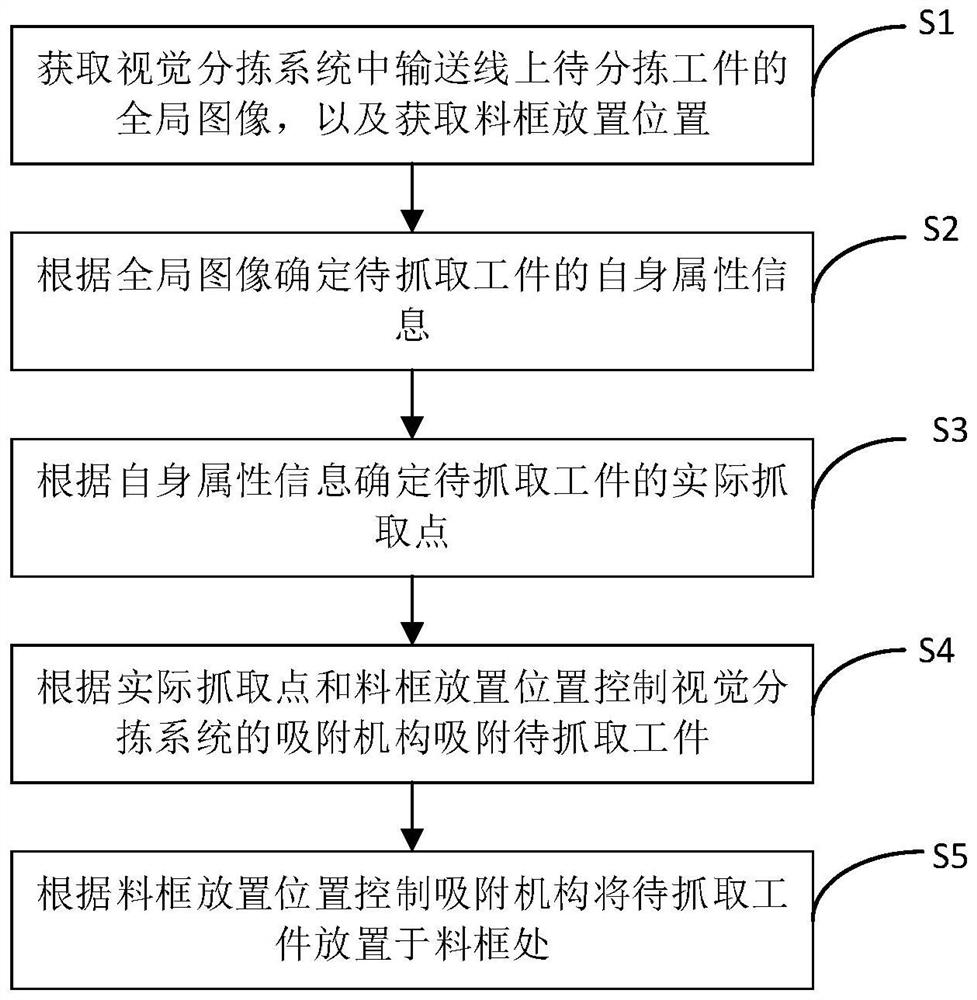

[0030] Embodiments of the present invention are described in detail below, and the embodiments described with reference to the drawings are exemplary, and embodiments of the present invention are described in detail below.

[0031] In order to solve the above problems, the embodiment of the first aspect of the present invention proposes a visual sorting system, which can realize the automatic sorting function and improve the sorting efficiency.

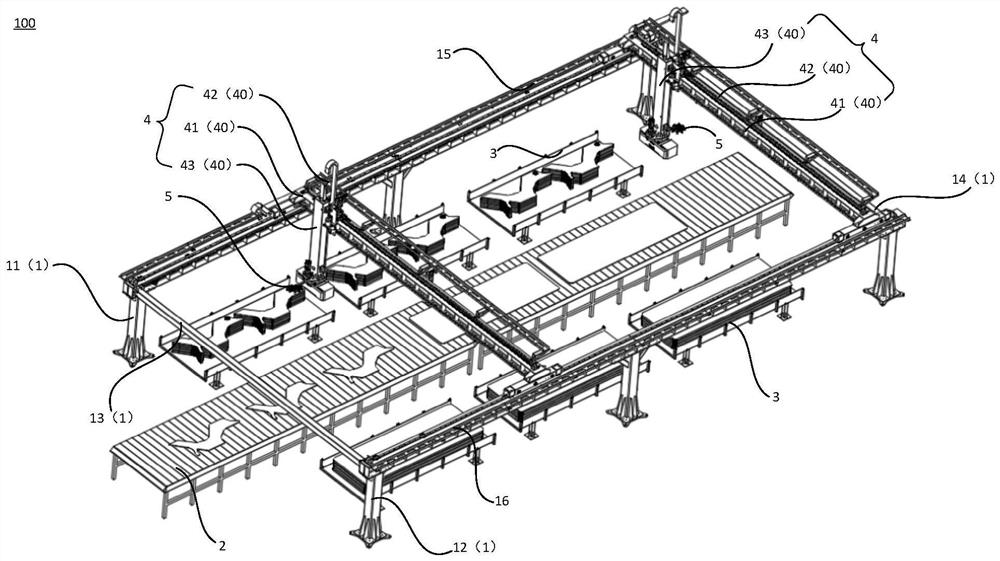

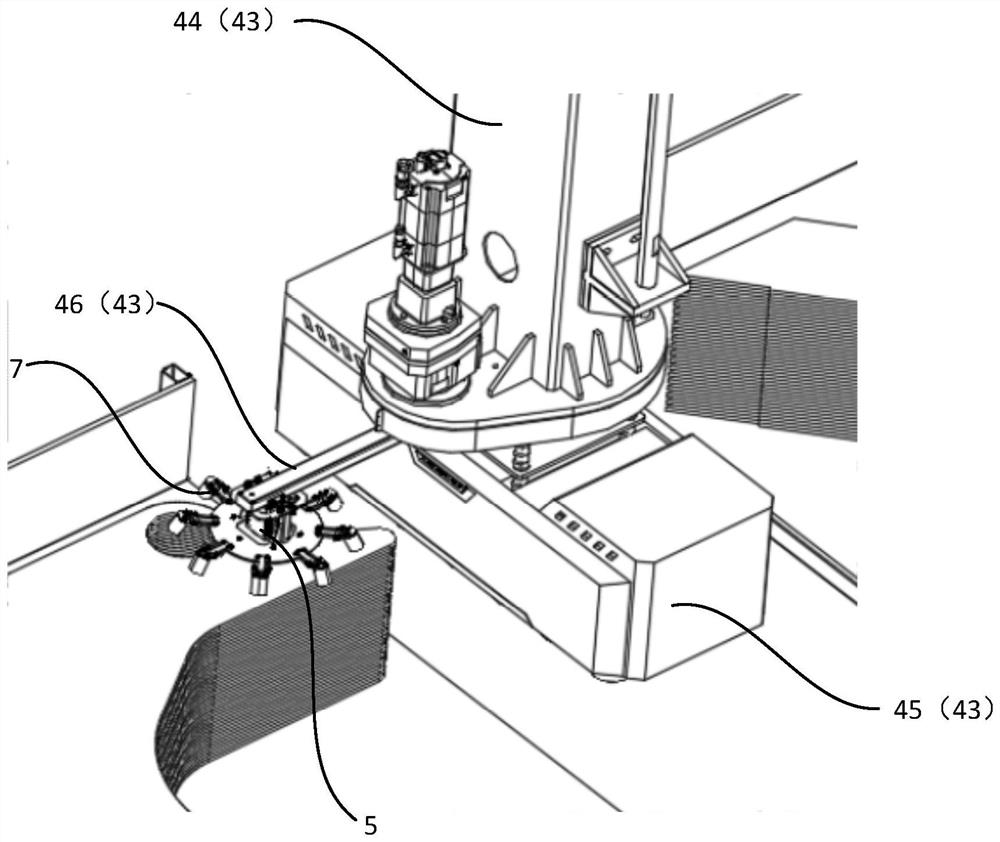

[0032] Refer below figure 1 Describe the visual sorting system of the embodiment of the present invention, such as figure 1 As shown, the visual sorting system 100 includes a truss mechanism 1, a conveying line 2, a material frame 3, an adsorption mechanism 4, an image acquisition device 5 and a control device 6 (not shown in the figure).

[0033] Among them, such as figure 1 As shown, the truss mechanism 1 includes a first truss 11, a second truss 12, a first connecting frame 13 and a second connecting frame 14, the first truss 11 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com