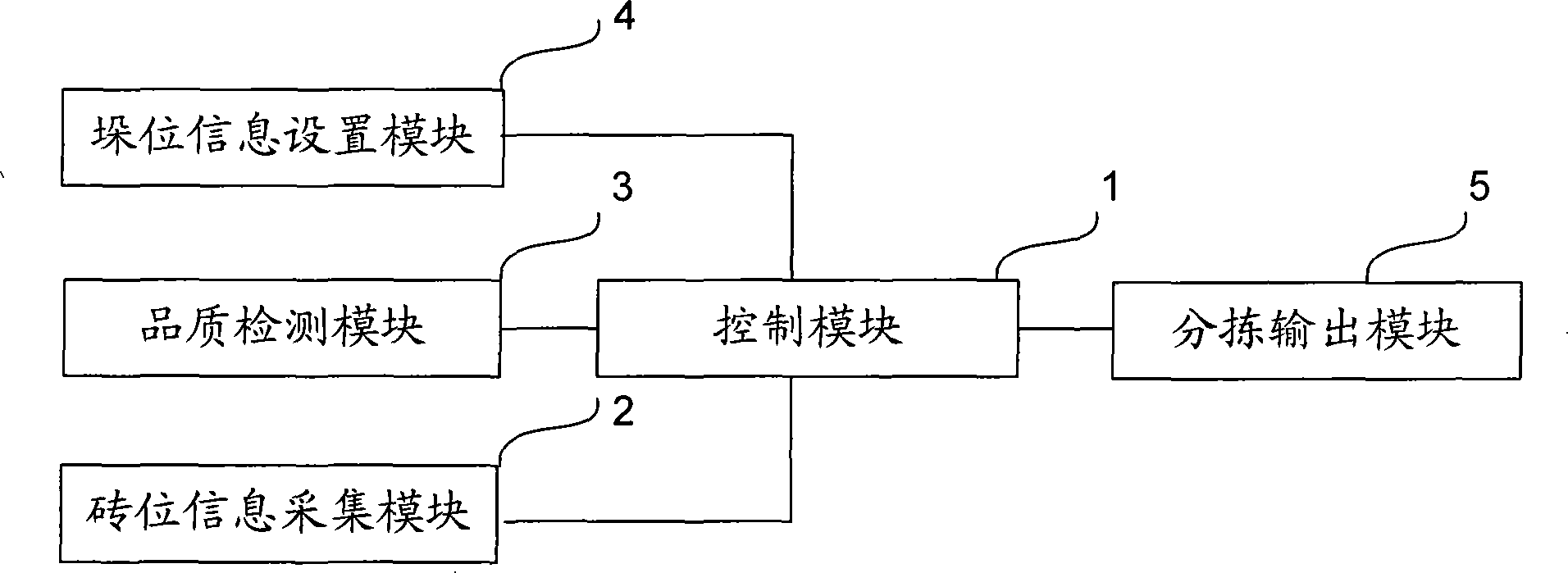

Automatic sorting device, and method and system

An automatic sorting system and automatic sorting technology, applied in the direction of sorting, sequence/logic controller program control, electrical program control, etc., can solve problems such as high labor intensity, increased production costs, and damage to finished bricks. Achieve the effect of improving the degree of automation, saving production costs and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

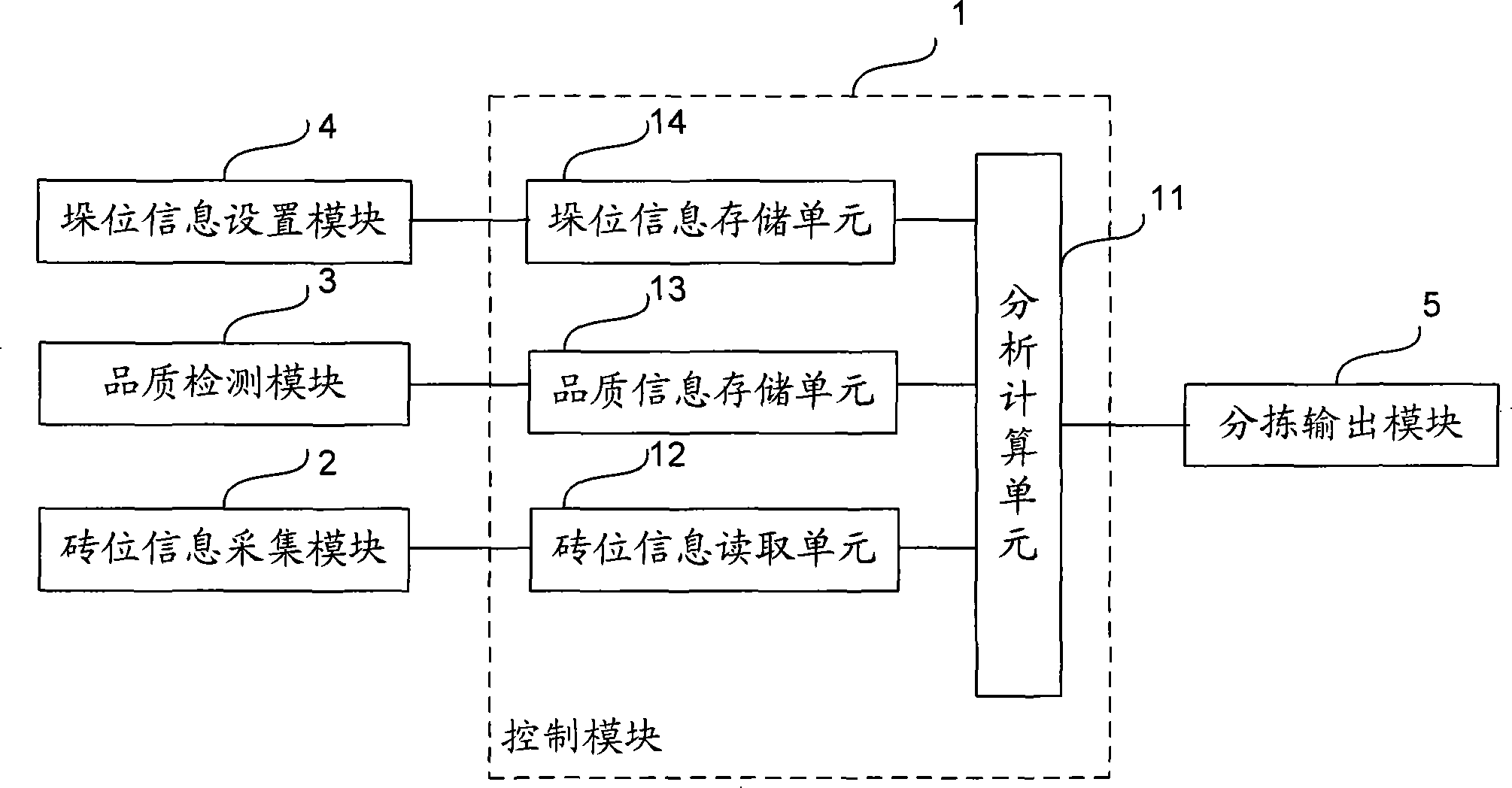

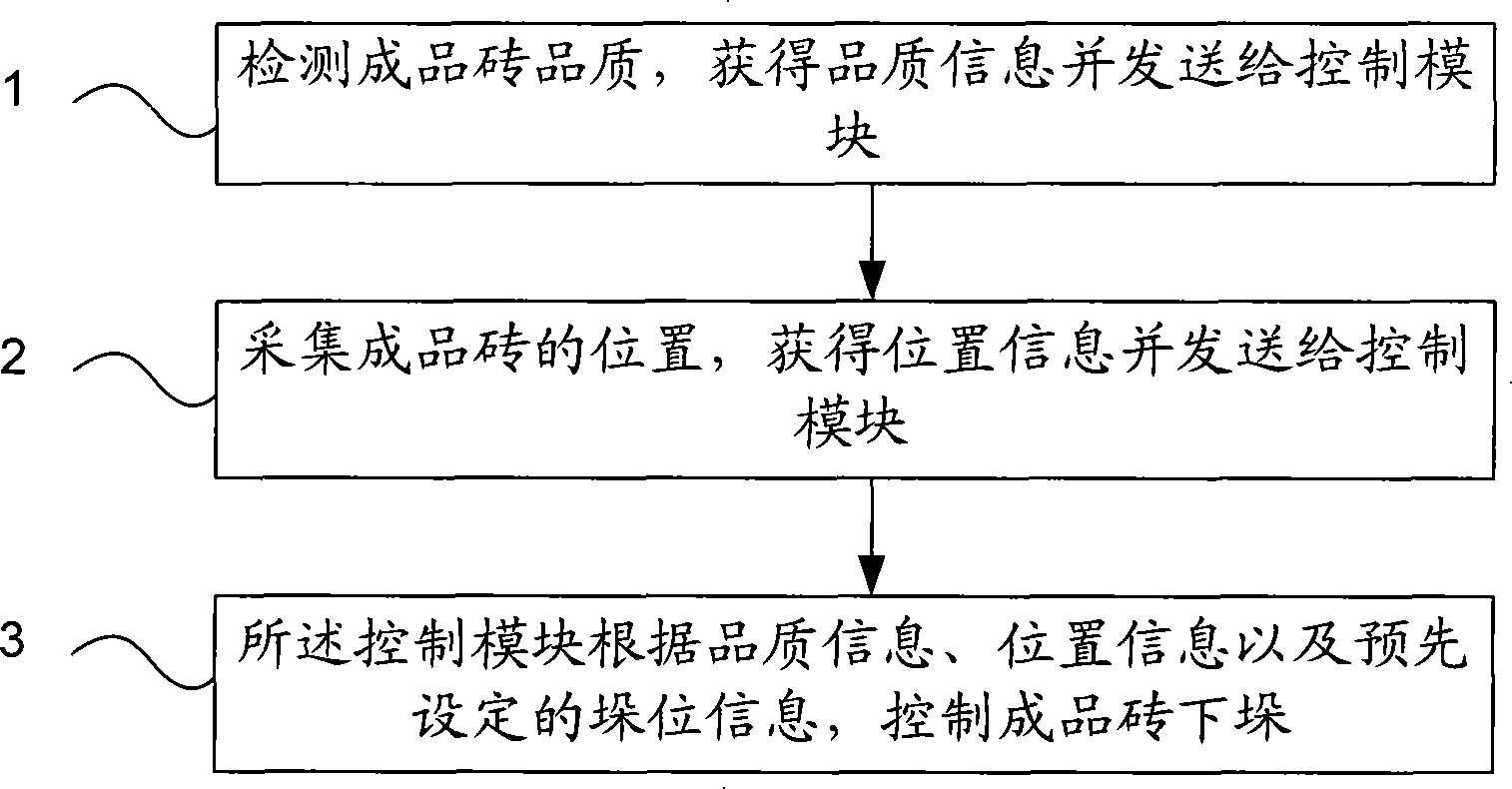

[0059] The specific implementation is as follows: after the system is powered on, the stack information is set by the stack information setting module 4, that is, the data request for the quality of finished bricks is carried out for each stack, and the data request is delivered to the stack information of the control module 1. Storage unit 14, after the system is reset, the finished bricks are transported to the quality inspection module 3 through the conveyor belt mechanism, and the quality inspection module 3 detects various quality information of the finished bricks, such as flatness and size, and sends the quality information into the The quality information storage unit 13 in the control module 1 continues to transport the finished bricks to the stack by the conveyor belt mechanism. The signal is delivered to the brick position information reading unit 12 of the control module 1, and the control module 1 sends a control signal to the quality inspection module 3 after rece...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com