Non-overturning mold hopper for aerated concrete production

An air-entrained concrete, non-turning technology, applied in the direction of molds, manufacturing tools, ceramic molding machines, etc., can solve the problems that the mold hopper cannot be demoulded at the same time, and the safety hazards of the demoulding method, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The following will clearly and completely describe the technical solutions in the embodiments of the invention with reference to the drawings in the embodiments of the invention. The embodiments described below by referring to the figures are exemplary only for explaining the invention and should not be construed as limiting the invention.

[0034] The following describes the embodiments according to the overall structure of the invention.

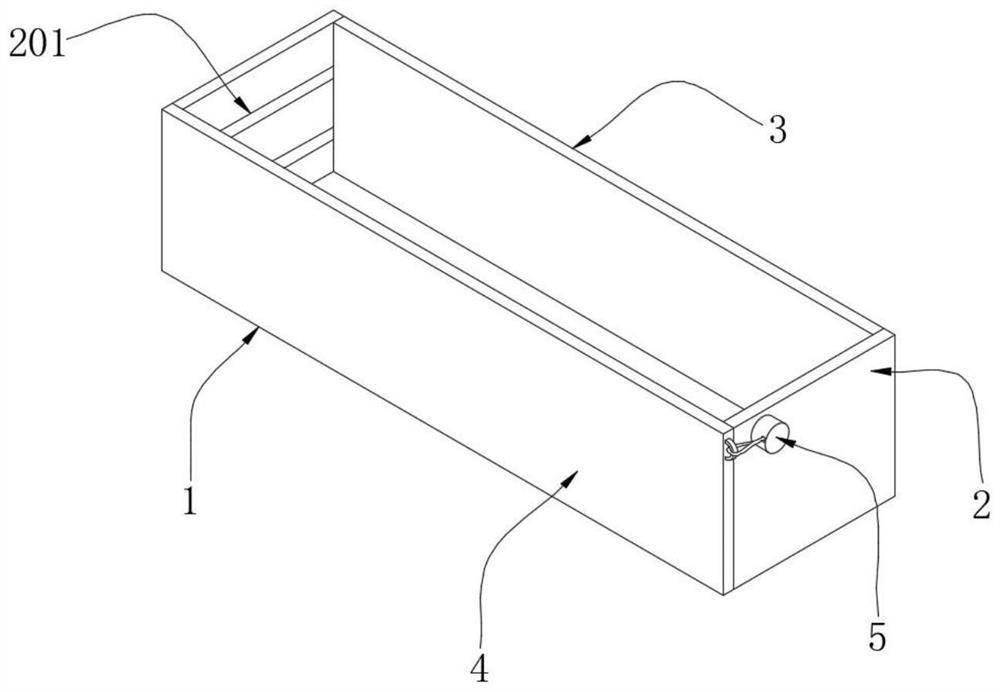

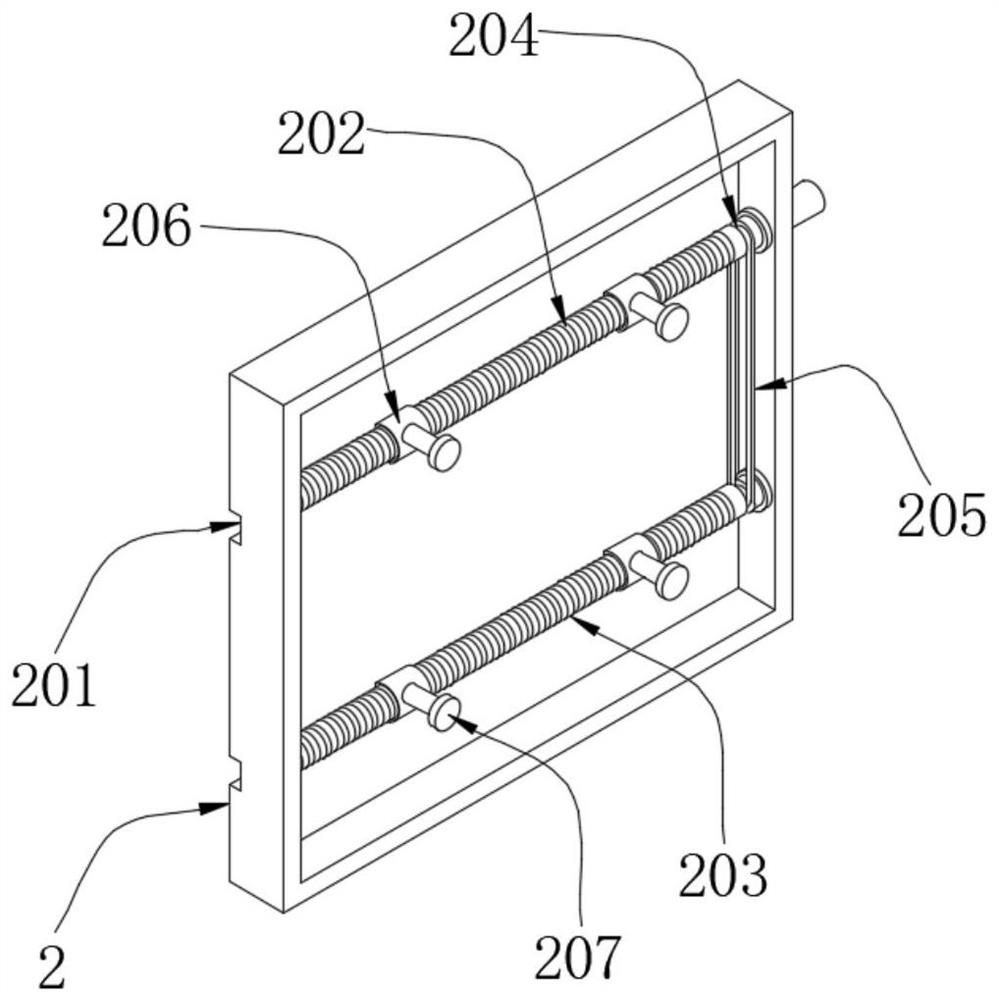

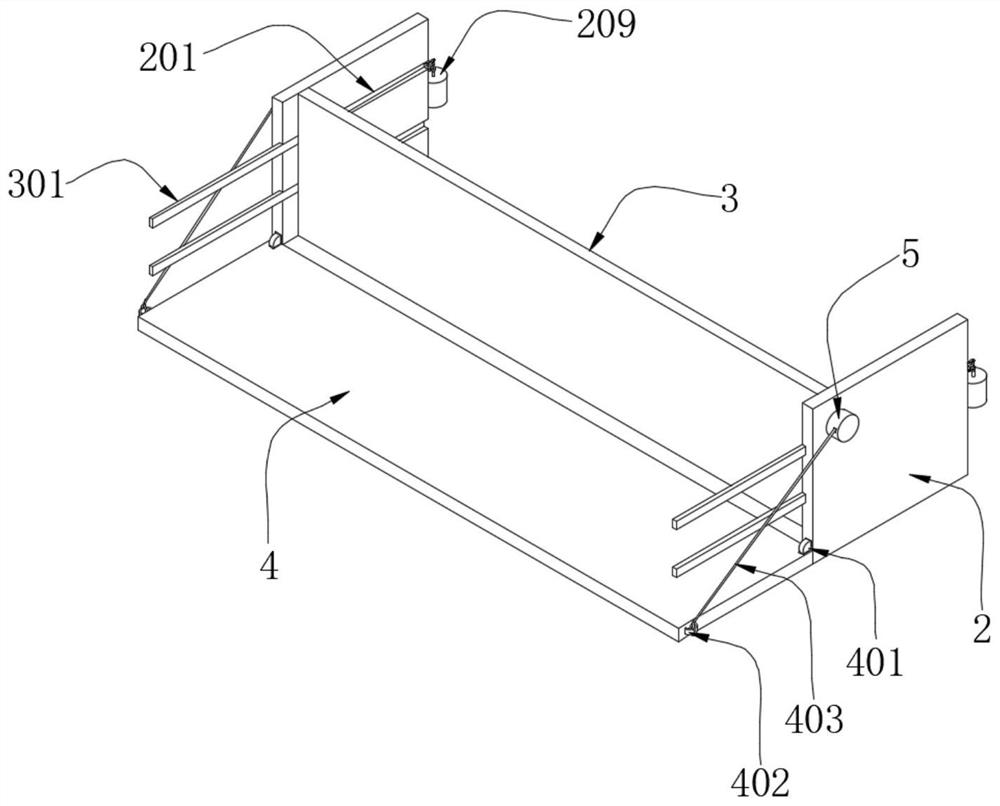

[0035] A non-reversing mold hopper for the production of aerated concrete, such as Figure 1-7As shown, it includes a mold hopper 1, a moving plate part 3 and a rotating plate part 4. Side plate parts 2 are provided on both sides of the mold hopper 1, and two sets of chute 201 are provided on the opposite side of each set of side plate parts 2. , the inside of the side plate part 2 is provided with a No. 1 worm 202, and the inside of the side plate part 2 is located below the No. Groove 204, and transmission belt 205 is connected ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com