The gate mechanism of the steel ball conveying insulation pipe

A technology of heat preservation pipes and steel balls, which is applied in the direction of mechanical equipment, engine components, valve operation/release devices, etc., to achieve the effect of performance improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] Below in conjunction with accompanying drawing and embodiment the present invention is further described:

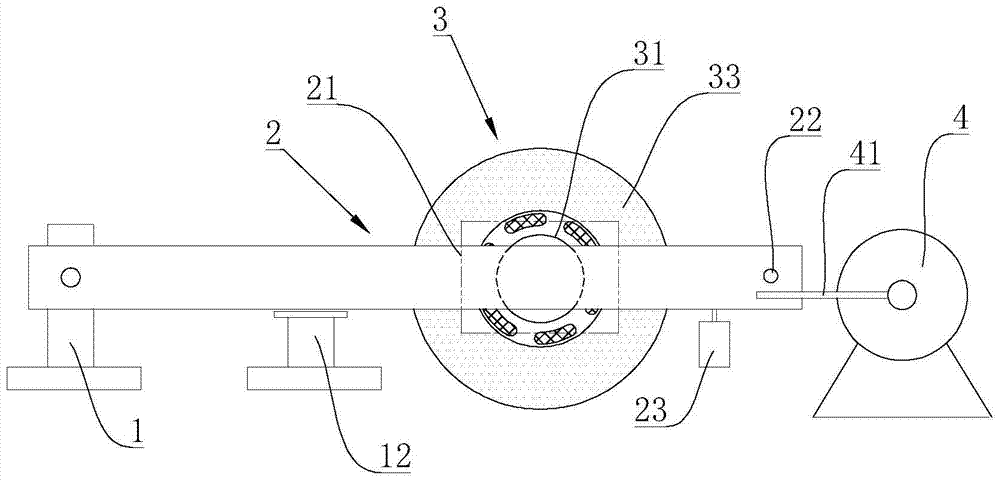

[0021] The gate mechanism of the steel ball conveying insulation pipe is characterized in that it includes a base 1 and a cross bar 2, the base 1 is fixed, one end of the cross bar 2 is hinged to the base 1, and the cross bar 2 is provided with a stopper 21, also includes a driving mechanism for driving the cross bar 2 to swing around its hinge point.

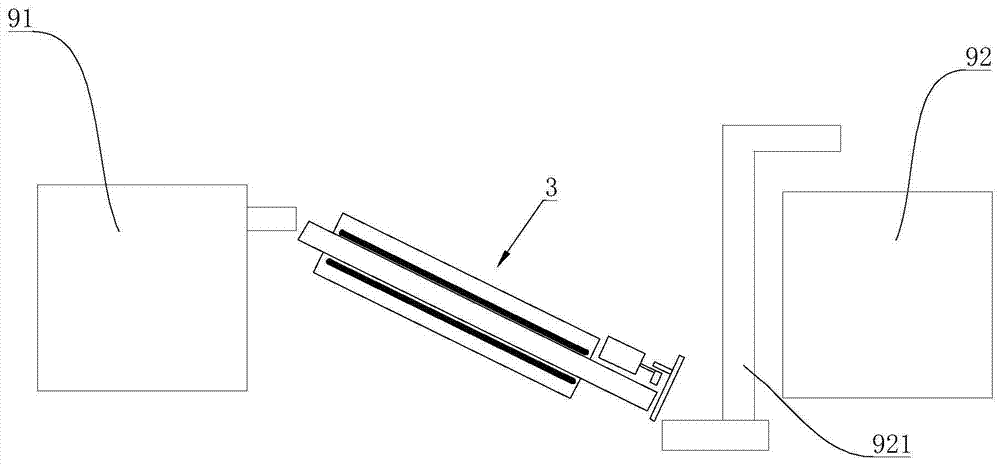

[0022] The gate mechanism of the present invention is used for intermittently opening the steel ball conveying insulation pipe 3 of the ball mill steel ball manufacturing equipment. Such as figure 1 As shown, the steel ball conveying heat preservation pipe 3 is located between the forging machine 91 and the quenching pool 92, the steel ball conveying heat preservation pipe 3 is arranged obliquely, and the high temperature steel balls sent out by the forging machine 91 can roll along the steel ball conveying heat p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com