Trimming and polishing process for hot glass on production line for manufacturing float glass

A float glass and production line technology, applied in the field of trimming and polishing technology, can solve the problems of glass edge uniformity and low smoothness, and achieve the effect of precise glass size and straight and smooth trimming

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

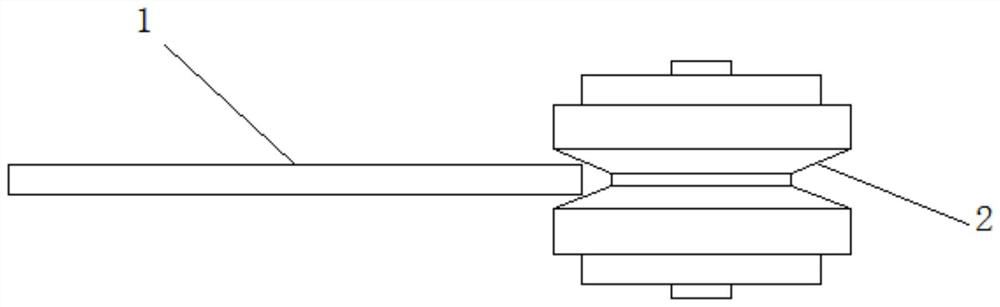

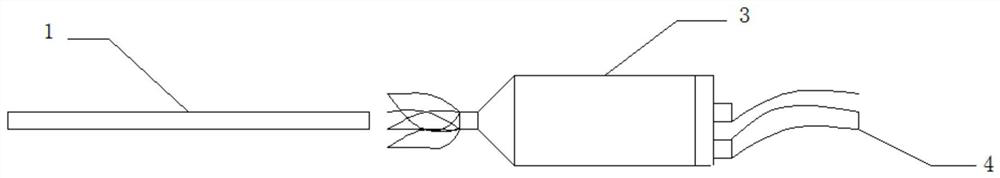

[0041]On the 600t / d float production line, the original plate width is 4000mm, and when producing 5mm glass, the main line glass plate speed is 8-9m / min. The size of the board after online cutting is 3662×2442mm, and it is trimmed and polished.

[0042] In the trimming and polishing process of hot glass on the production line for manufacturing float glass, the temperature of the high-temperature glass is 500-650°C, and the specific process is as follows:

[0043] (1) After the longitudinal edge breaking process in area B of the annealing kiln of the flat glass float production line, the glass plate 1 enters the longitudinal edge trimming and polishing area. The kiln roller table runs at a suitable speed, and the longitudinal trimming and polishing unit parts arranged on both sides of the annealing kiln run to the middle of the annealing kiln at the same time, so that the V-shaped groove 2 of the polishing wheel touches the longitudinal edge of the glass. When the flame gun is...

Embodiment 2

[0049] On the 600t / d float production line, the original plate width is 4000mm, and when producing 8mm glass, the main line glass plate speed is 5-7m / min. The size of the board surface after online cutting is 3660×2440mm, and it is trimmed and polished.

[0050] In the trimming and polishing process of hot glass on the production line for manufacturing float glass, the temperature of the high-temperature glass is 500-650°C, and the specific process is as follows:

[0051] (1) After the longitudinal edge breaking process in area B of the annealing kiln of the flat glass float production line, the glass plate 1 enters the longitudinal edge trimming and polishing area. The kiln roller table runs at a suitable speed, and the longitudinal trimming and polishing unit parts arranged on both sides of the annealing kiln run to the middle of the annealing kiln at the same time, so that the V-shaped groove 2 of the polishing wheel touches the longitudinal edge of the glass. When the fla...

Embodiment 3

[0057] In the 600t / d float production line, the original plate width is 4000mm, and when producing 12mm glass, the main line glass plate speed is 3-5m / min. The size of the board surface after online cutting is 3660x2440mm, and it is trimmed and polished.

[0058] In the trimming and polishing process of hot glass on the production line for manufacturing float glass, the temperature of the high-temperature glass is 500-650°C, and the specific process is as follows:

[0059] (1) After the longitudinal edge breaking process in area B of the annealing kiln of the flat glass float production line, the glass plate 1 enters the longitudinal edge trimming and polishing area. The kiln roller table runs at a suitable speed, and the longitudinal trimming and polishing unit parts arranged on both sides of the annealing kiln run to the middle of the annealing kiln at the same time, so that the V-shaped groove 2 of the polishing wheel touches the longitudinal edge of the glass. When the fl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com