Multi-working-face industrial angle iron

A multi-face, angle iron technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

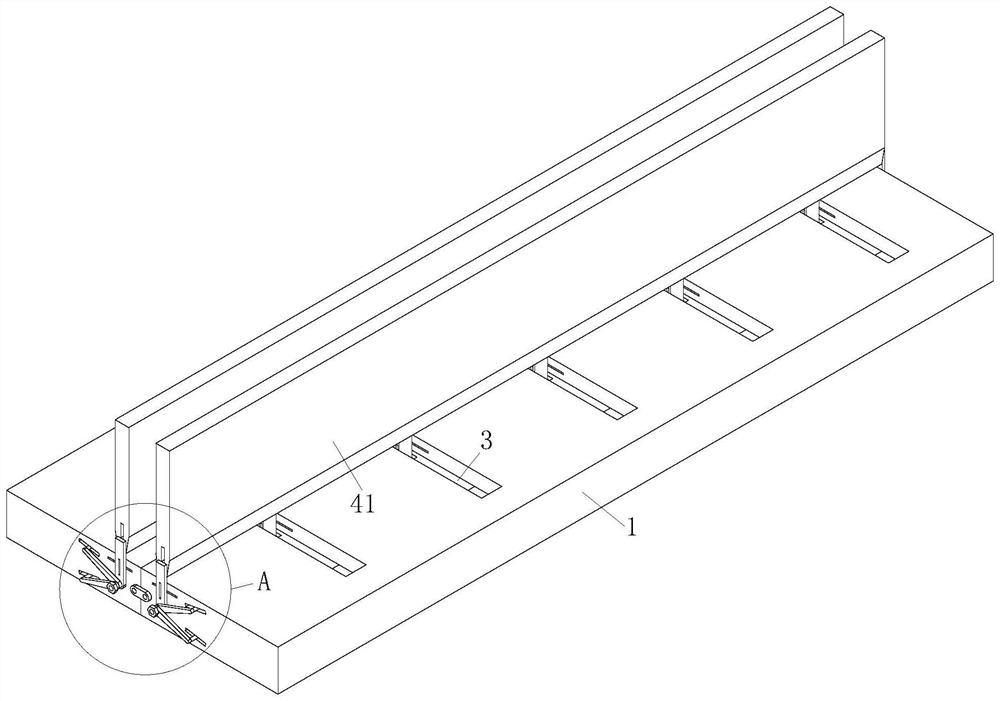

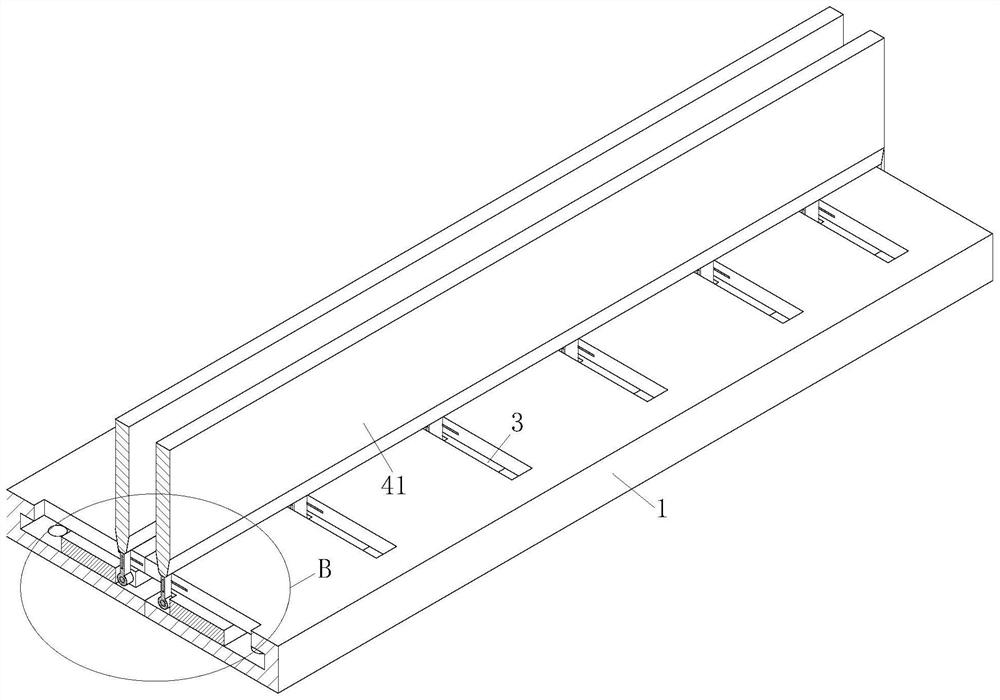

Image

Examples

Embodiment approach

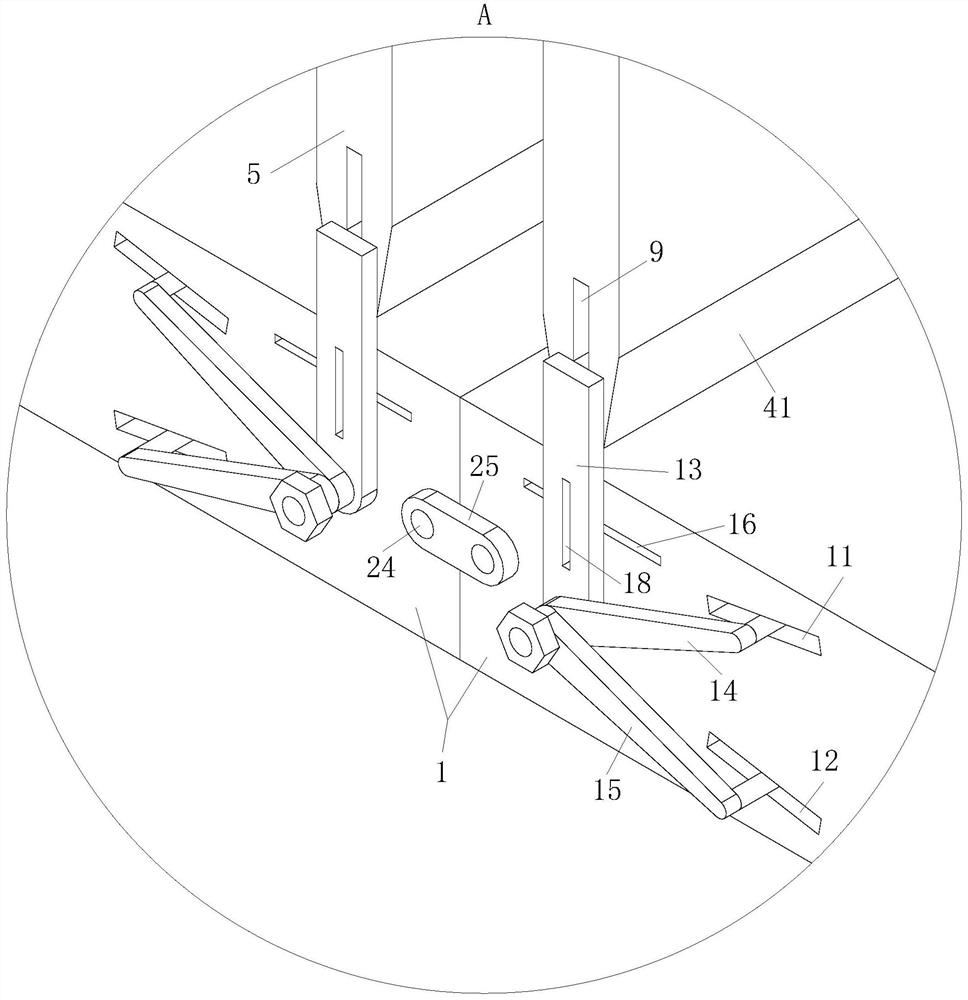

[0054] As an embodiment of the present invention, the connecting unit includes:

[0055] Rotation groove 6, said rotation groove 6 vertically penetrates on said horizontal plate 42, and said rotation groove 6 is located on the opposite end of two said horizontal plates 42;

[0056] Rotating rod 7, the rotating rod 7 is fixed on the lower end of the upper plate 41, and the lower end of the rotating rod 7 extends into the inside of the rotating groove 6 through the chute 3;

[0057] Connecting rod 8, the connecting rod 8 is arranged on the two side walls of the rotating groove 6 along the length direction of the base 1, and the rotating rod 7 is connected to the inside of the rotating groove 6 through the connecting rod 8 ;

[0058] During work, the rotating groove 6 vertically runs through the horizontal plate 42, and the rotating groove 6 is located on the opposite end of the two horizontal plates 42, each rotating groove 6 corresponds to the position of the chute 3, and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com