Pressing device of section steel stack packing line

A compression device and packaging line technology, applied in packaging, transportation and packaging, packaging/bundling items, etc., can solve problems such as dangerous accidents, increase the compression of mechanical devices, large height drop, etc. The effect of tightness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

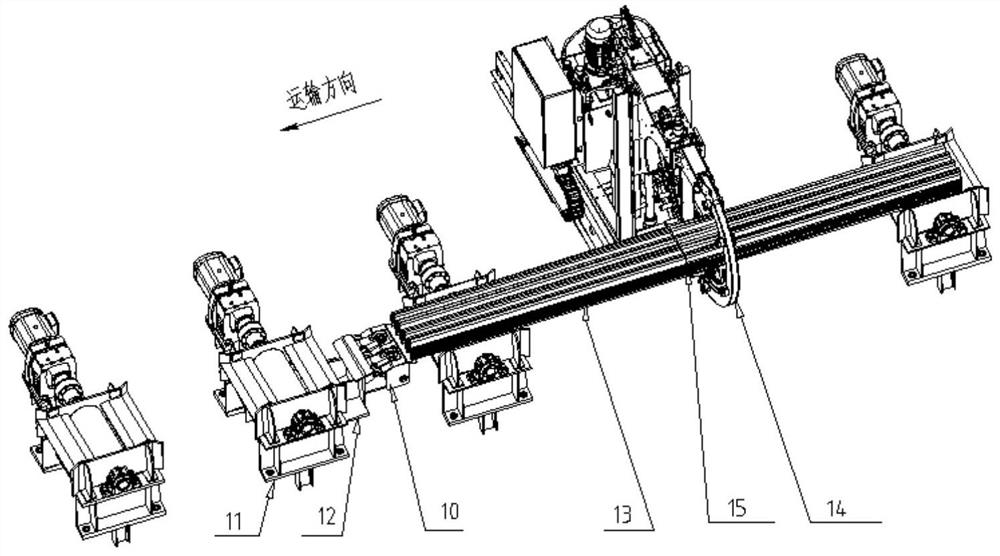

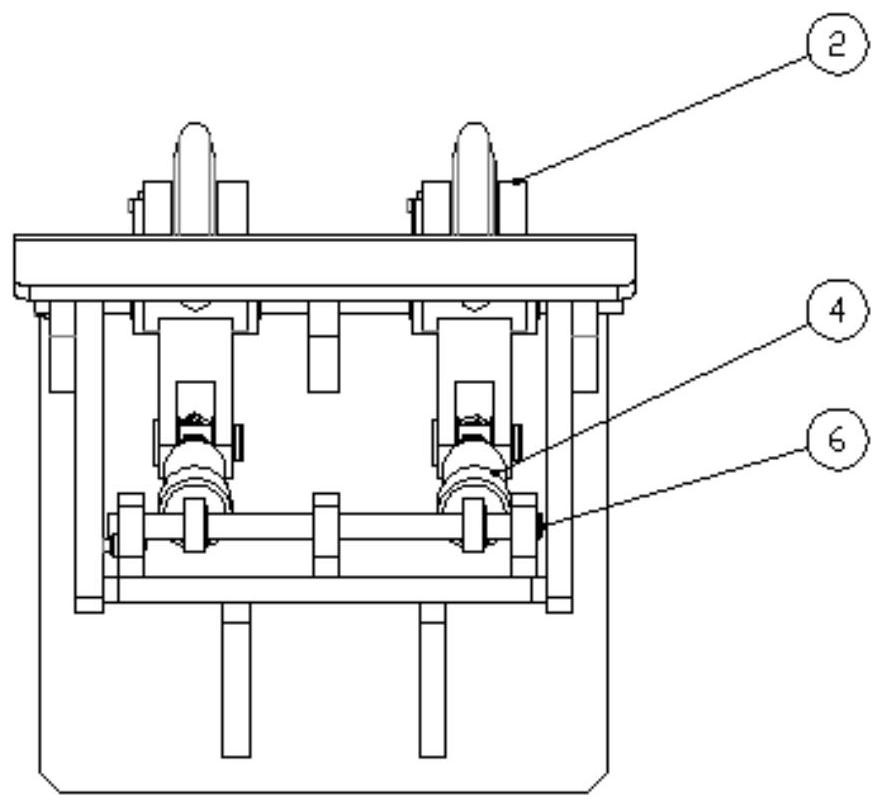

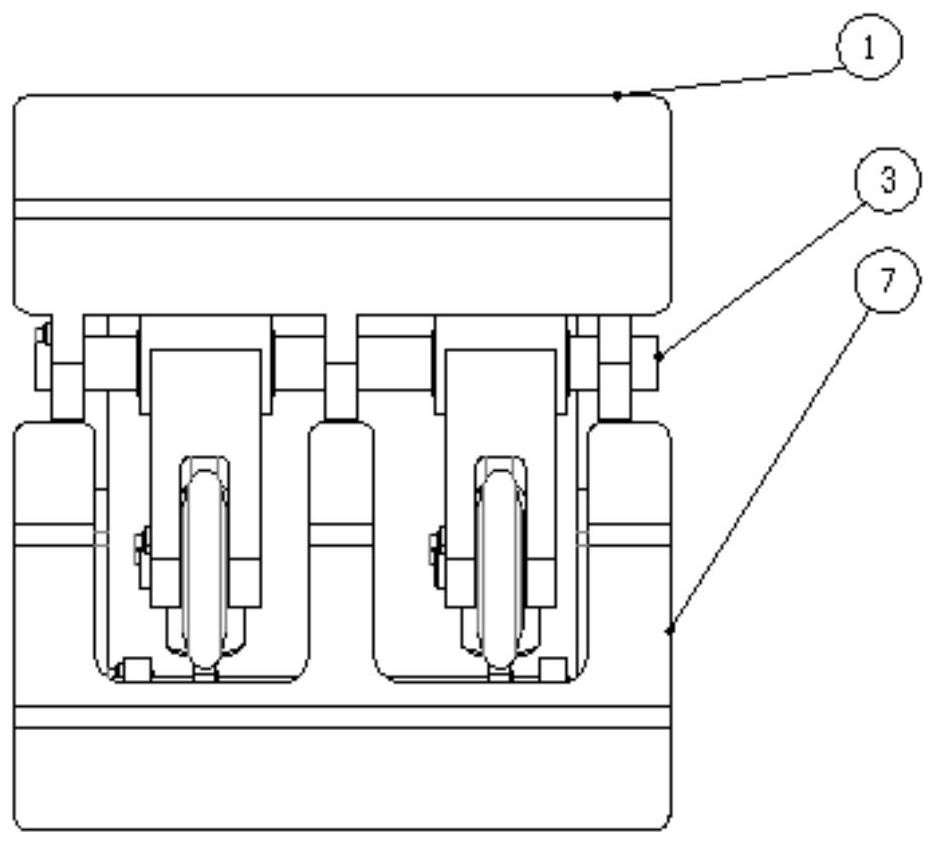

[0026] From figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 It can be seen that the compression device of the profile steel stack packing line of the present invention includes a main bracket 1, a swing arm assembly 2, a main shaft 3, a spring rod assembly 4, a small shaft 6, and a guide plate 7; the main bracket 1 and the guide plate 7 are connected to form The outer frame; the swing arm assembly 2 is connected with the main support 1 through the main shaft 3, the spring rod assembly 4 is connected with the guide plate 7 through the small shaft 6; the spring rod assembly 4 is connected with the swing arm assembly 2.

[0027] When the profiled steel pile is transported through the conveyor line after being packaged, the swing arm assembly 2 will rotate and swing downward around the axis of the main shaft 3 under the action of its own weight, driving the spring rod assembly 4 to move, and then the spring in the spring rod assembly 4 The elastic force of the packing ...

Embodiment 2

[0030] From figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 It can be seen that the compression device of the profile steel stack packing line of the present invention: the compression device also includes two upper and lower limit units, the two limit units are located on the same side of the main bracket 1, each limit unit includes a fixed plate I8, fixed Plate I8 is fixed on the outermost side of the upper connection hole or the lower connection hole of the main bracket 1 through fasteners, and one side of it is stuck in the groove at the outer circle of one end of the main shaft 3 or the small shaft 6 .

[0031] Wherein, the groove at the outer circle of the main shaft 3 or the small shaft 6 is a straight side, which is in contact with the side of the fixing plate I8.

[0032] The two fixing plates I8 respectively press the main shaft 3 and the small shaft 6 to restrain the rotation and axial movement of the two shafts, so that the swing arm assembly 2 set on t...

Embodiment 3

[0035] From figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Figure 6 It can be seen that the compression device of the profile steel stack packing line of the present invention: the swing arm assembly 2 includes at least two groups of swing arm units arranged symmetrically from left to right, and each group of swing arm units includes a swing arm bracket 2-1, a roller 2-2, a connecting Axis 2-5, roller shaft 2-6; the roller 2-2 is located between the left and right forearms of the upper arm of the swing arm support 2-1, and the roller shaft 2-6 passes through the left and right forearms of the upper arm of the swing arm support 2-1, Roller 2-2 and cooperate with the inner holes of the three; connecting shaft 2-5 passes through the left and right small arms of the lower arm of swing arm bracket 2-1 and cooperates with the inner holes of both; connecting shaft 2-5 and spring rod assembly 4 connection; the main shaft 3 passes through the upper connecting hole of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com