A self-shock electric energy recovery hub

An electric energy recovery and hub technology, applied in the direction of hubs, wheels, highly elastic wheels, etc., can solve the problems of non-vibration of the hub, the loss of braking kinetic energy cannot be utilized, etc., and achieve the effect of reasonable energy and rational utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

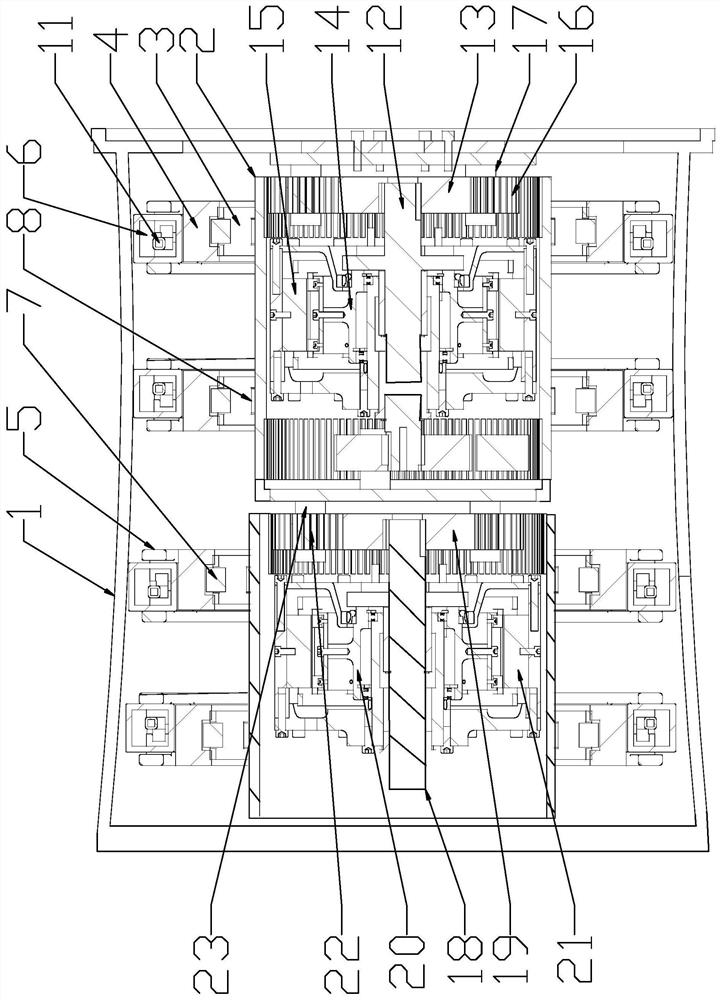

[0022] The technical solutions of the present invention will be further specifically described below through the embodiments and in conjunction with the accompanying drawings.

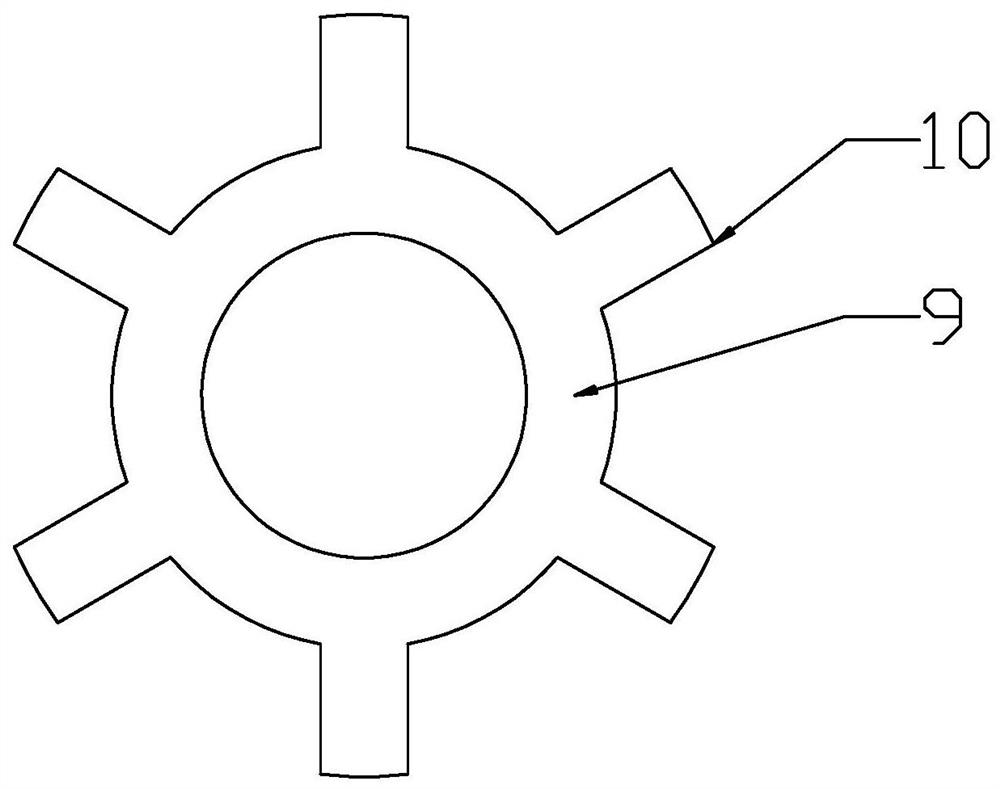

[0023] like figure 1 , figure 2 As shown, the present invention is a self-damping electric energy recovery hub, including a rim 1 and a central hub 2, and several groups of airbag shock absorbing devices are arranged between the central hub 2 and the rim 1 along the circumference. During the turning process of the hub, the force will be uneven. Multiple sets of airbag damping devices are set on the central hub 2, so that different sets of airbag damping devices can form different air flow changes according to their different forces, and the damping effect is better. good.

[0024] The airbag damping device is fixed on the outer surface of the central hub 2, the central hub 2 is provided with a driving mechanism and an electric energy recovery device, the driving mechanism is connected to the central...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com