Lifting rib and clothes processing equipment

A rib-lifting and uniform technology, applied in the field of clothing processing equipment, can solve the problems of easy residual lint on the filter, difficulty in cleaning the filter, affecting the filtering effect, etc., and achieve the effect of excellent filtering effect, avoiding mutual influence and facilitating processing.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

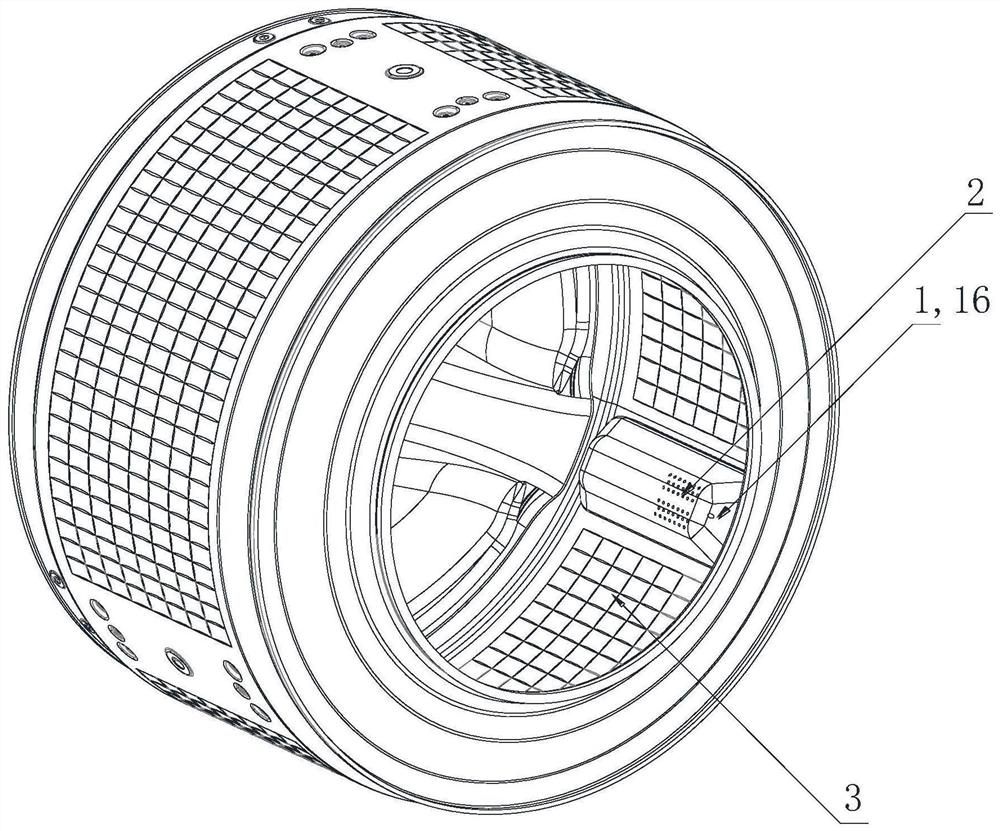

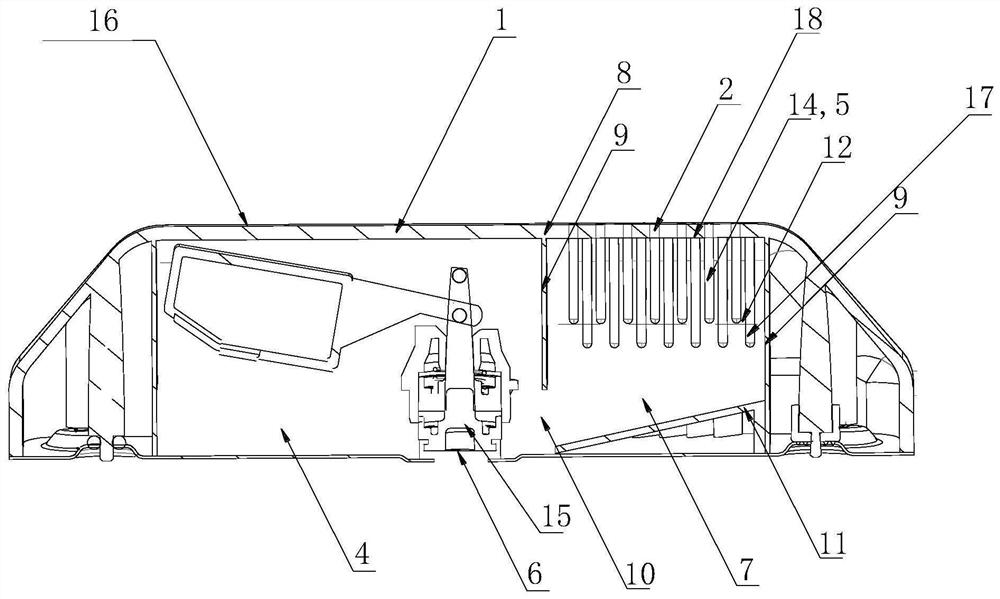

[0036] The washing machine is provided with a washing tub for containing washing water, washing clothes, and discharging washing water, and the inner wall 3 of the washing tub often needs to be provided with lifting ribs for lifting the water flow. The lifting rib includes a shell 1 arranged on the inner wall 3 of the washing tub, and an inner cavity 4 is formed between the shell 1 and the inner wall 3 of the washing tub. The lifting rib actually uses the outline of the outer shell 1 to achieve the effect of lifting the water flow, and the inner cavity 4 is a cavity, so in order to save space, the internal parts of the washing machine can be arranged in the cavity of the inner cavity 4 . At present, there are existing patents that use the space of the inner cavity 4 to set up a filter structure, and any side wall 8 on the shell 1 is provided with a through hole 2 for water flow in and out, so that the water flow in the washing tub can flow into the inner cavity 4 through the thro...

Embodiment 2

[0047] On the basis of the above-mentioned embodiments, this embodiment provides a lifting bar, and a comb-shaped filter structure 14 is also arranged in the lifting bar, the difference is that the structure of the comb teeth 17 of the comb-shaped filter structure 14 of this embodiment is different from The structure of the comb teeth 17 in Embodiment 1. In the present embodiment, the comb teeth 17 are similar to a "tree" structure, such as Image 6 As shown in the figure, the comb teeth 17 include a cylindrical rod 19 on which is provided an outwardly protruding, "branch" shaped filter rod 20 . Same as the embodiment 1, the cylindrical rod 19 itself can play the effect of hanging slag such as shavings, and the slag such as shavings can be clamped between adjacent cylindrical rods 19 . And the filter rod 20 similar to "twigs" arranged on the cylindrical rod 19 can also play the effect of making slag such as wire scraps hang on it, and can make impurities such as wire scraps b...

Embodiment 3

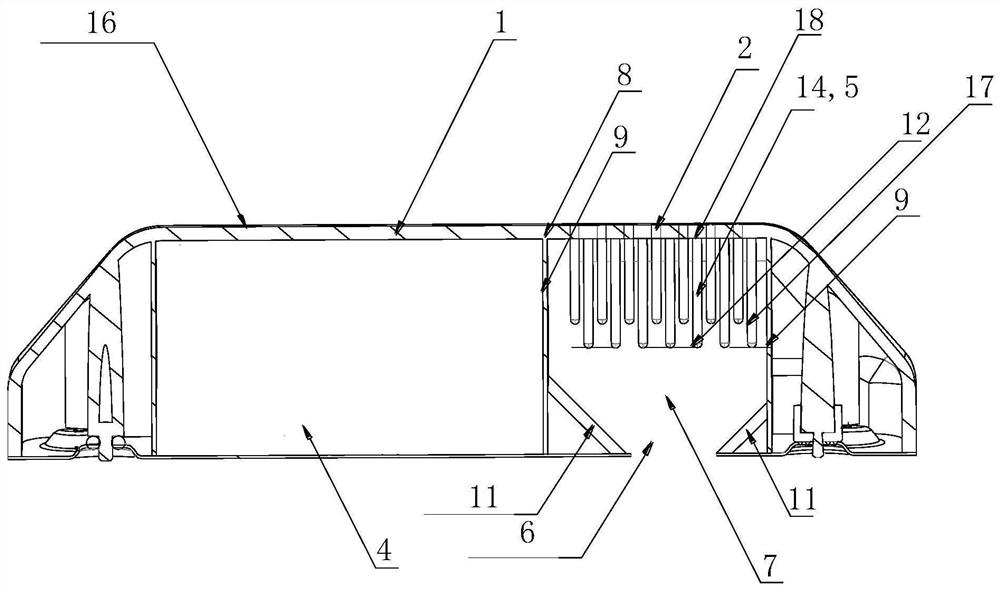

[0053] The inner wall 3 of the washing tub is often provided with lifting ribs 16 for enhancing water flow. The lifting ribs 16 include a shell 1 which is arranged on the inner wall 3 of the washing tub, and an inner cavity 4 is formed between the shell 1 and the inner wall 3 of the washing tub. The inner cavity 4 has a certain volume. In order to make full use of the space and save the volume, the required components in the washing machine can be arranged in the inner cavity 4 of the lifting rib 16 . For example, for the current non-porous washing machine, there is a patent that utilizes the inner cavity 4 of the lifting rib 16 to arrange a drainage device. For a non-porous washing machine, the inner wall 3 of the washing tub is usually provided with a drain port 6, and each lifting rib 16 covers at least one drain port 6, and the position of the inner cavity 4 of the lifting rib 16 and the position of the drain port 6 are correspondingly provided to block the drain port 6. T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com