Calibration method and device of liquid output equipment, equipment and medium

A technology of output equipment and calibration method, which is applied in the field of beverage equipment, can solve the problems of inflexible use and low precision of liquid output equipment, and achieve the effect of improving adaptability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

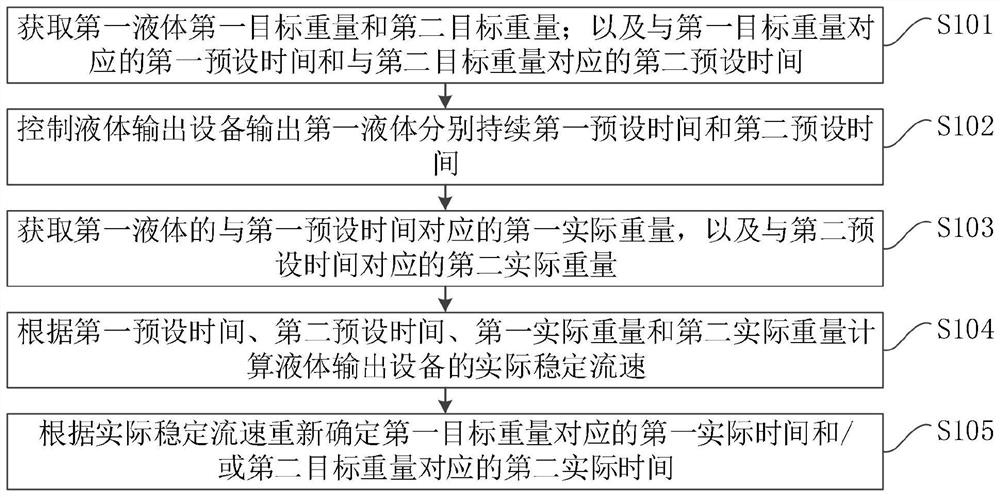

[0051] figure 1 It is a flowchart of a calibration method for a liquid output device proposed by an embodiment of the present invention. like figure 1 As shown, the calibration method of the liquid output device includes the following steps:

[0052] S101, acquiring a first target weight and a second target weight of the first liquid; and a first preset time corresponding to the first target weight and a second preset time corresponding to the second target weight;

[0053] It should be noted that the liquid output device may be a liquid delivery pump, wherein the liquid delivery pump includes an instruction receiving module, and the user inputs an instruction of a target weight to the liquid output device through the instruction receiving module; for example, output the first liquid ag, where the first One liquid can be plain syrup (the following still uses plain syrup as the first liquid for description), that is, when the user inputs 20g of plain syrup through the instructi...

Embodiment 2

[0101] Figure 5 It is a schematic block diagram of the calibration device of the liquid output device proposed by the embodiment of the present invention.

[0102] like Figure 5 As shown, the device 100 includes:

[0103] A target weight and preset time acquisition module 101, configured to acquire a first target weight and a second target weight; and a first preset time corresponding to the first target weight and a second preset time corresponding to the second target weight;

[0104] A control module 102, configured to control the liquid output device to output the first liquid for a first preset time and a second preset time respectively;

[0105] An actual weight acquisition module 103, configured to acquire a first actual weight of the first liquid corresponding to a first preset time, and a second actual weight corresponding to a second preset time;

[0106] The first calculation module 104 is used to calculate the actual stable flow rate of the liquid output devic...

Embodiment 3

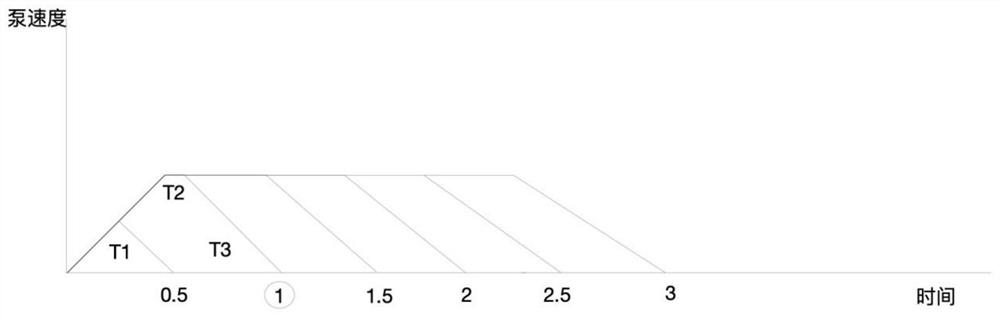

[0129] In order to ensure the accuracy of the output syrup volume, the pump needs to be calibrated before the equipment leaves the factory, and the corresponding syrup needs to be calibrated before receiving the order; the following two processes are conveniently described:

[0130] Among them, this scheme includes two stages of pump calibration. The first stage is the calibration of the pump before leaving the factory, which mainly calibrates the accuracy of each pump itself. The second stage is the calibration at the user end after the pump leaves the factory. For example, when calibrating the pumps in the first stage, all the pumps can be calibrated with plain syrup, and the second stage may involve caramel syrup according to needs, so that the output of caramel syrup will be affected. Calibrate the pump (other pumps that do not output caramel syrup also need to be calibrated according to the output liquid); the calibration method is introduced in detail below:

[0131] Fir...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com