Powder sampling equipment based on concrete production

A sampling equipment and concrete technology, applied in sampling devices and other directions, can solve problems such as affecting the accuracy of powder monitoring, large sampling area limitations, affecting the quality of concrete production, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

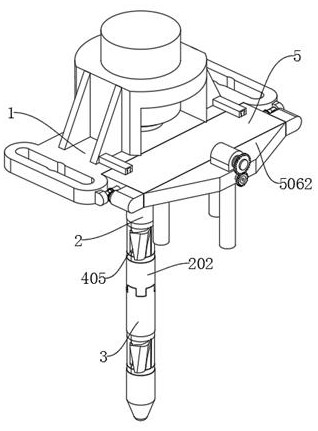

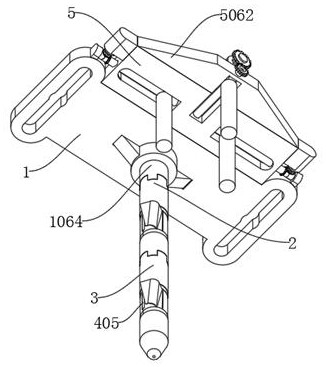

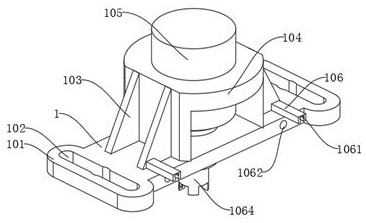

[0049] Example: Please refer to Figure 1 to Figure 9 :

[0050] The present invention proposes powder material sampling equipment based on concrete production, including: bearing support 1;

[0051] The load-bearing assembly structure is provided on the side of the load-bearing support 1, and the load-bearing assembly structure includes an installation shaft seat 1063. The installation shaft seat 1063 is installed on the bottom of the load-bearing support 1. At the same time, the inner side of the installation shaft seat 1063 is rotated and installed with a transmission shaft 1064; 2. The collection post 2 is installed at the end of the transmission shaft 1064; the collection bottom column 3, the collection bottom post 3 is installed at the end of the collection post 2; at the same time, the collection post 2 and the inside of the collection bottom post 3 are installed with a collection structure; the assembly support The plate 5 and the assembly support plate 5 are installe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com