Needle tube processing device for anesthesiology department

A processing device and an anesthesiology technology, applied in water supply devices, grain processing, needles, etc., can solve problems such as inability to separate needles, low work efficiency, and inability to automatically sterilize

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

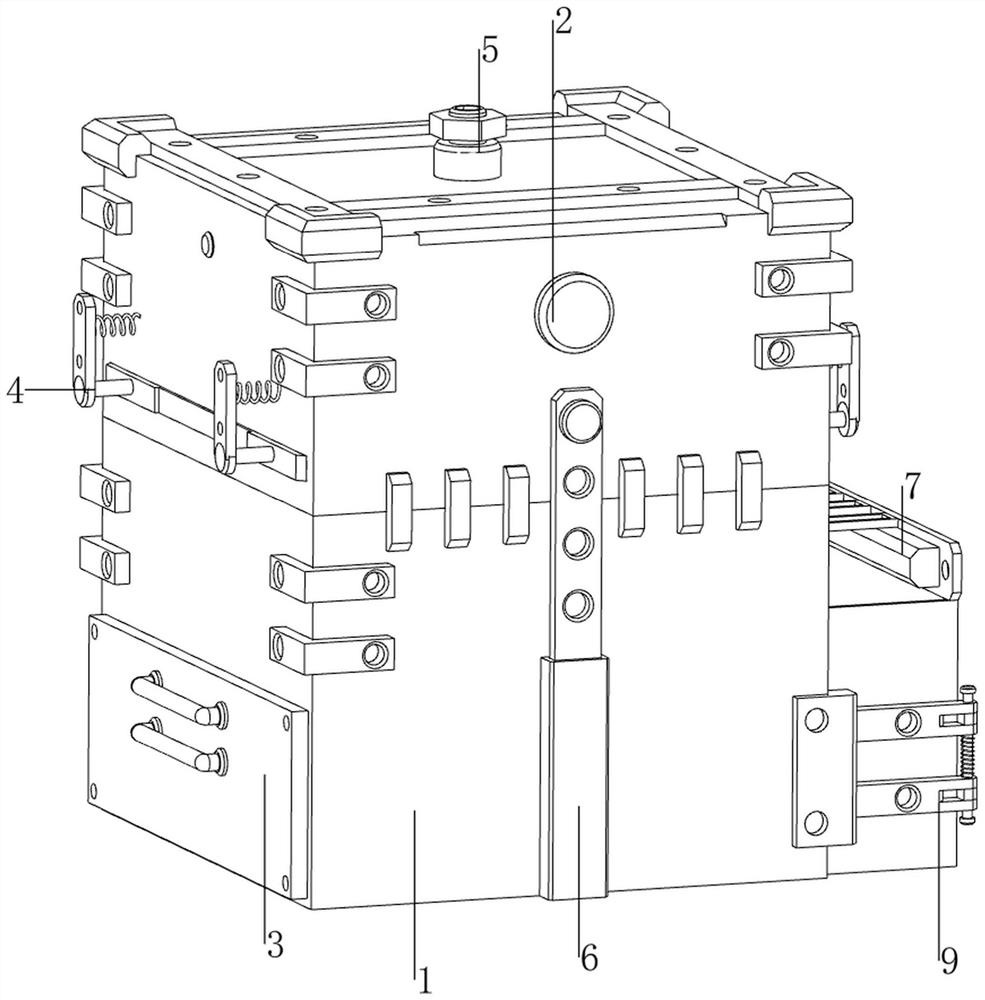

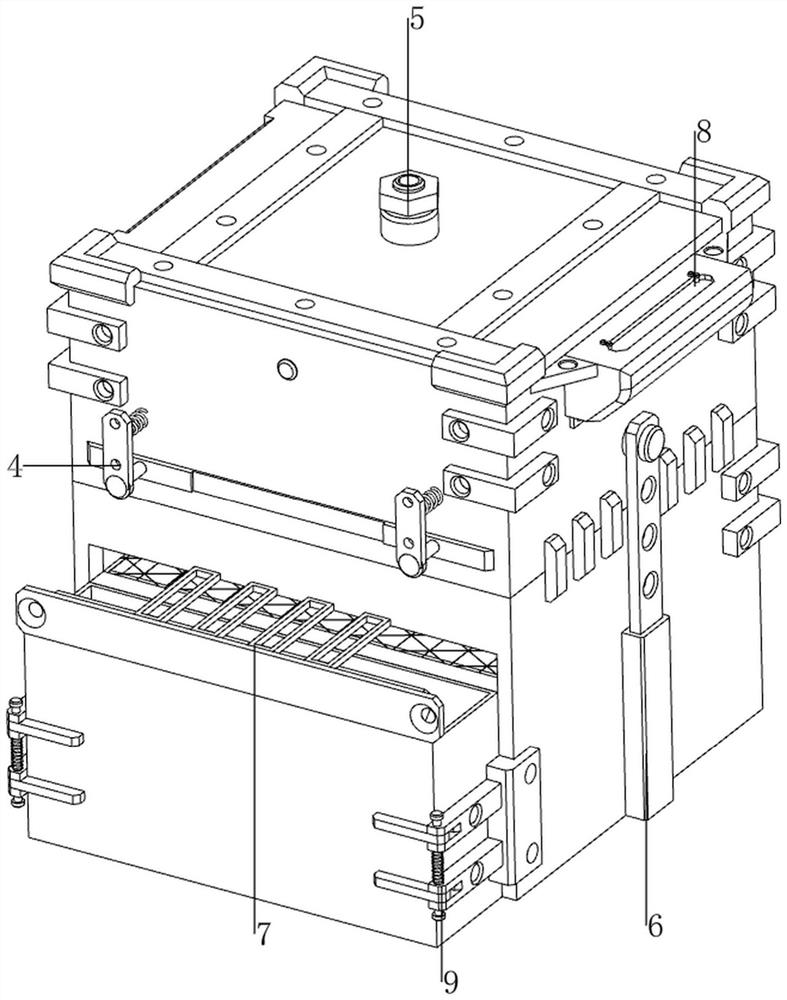

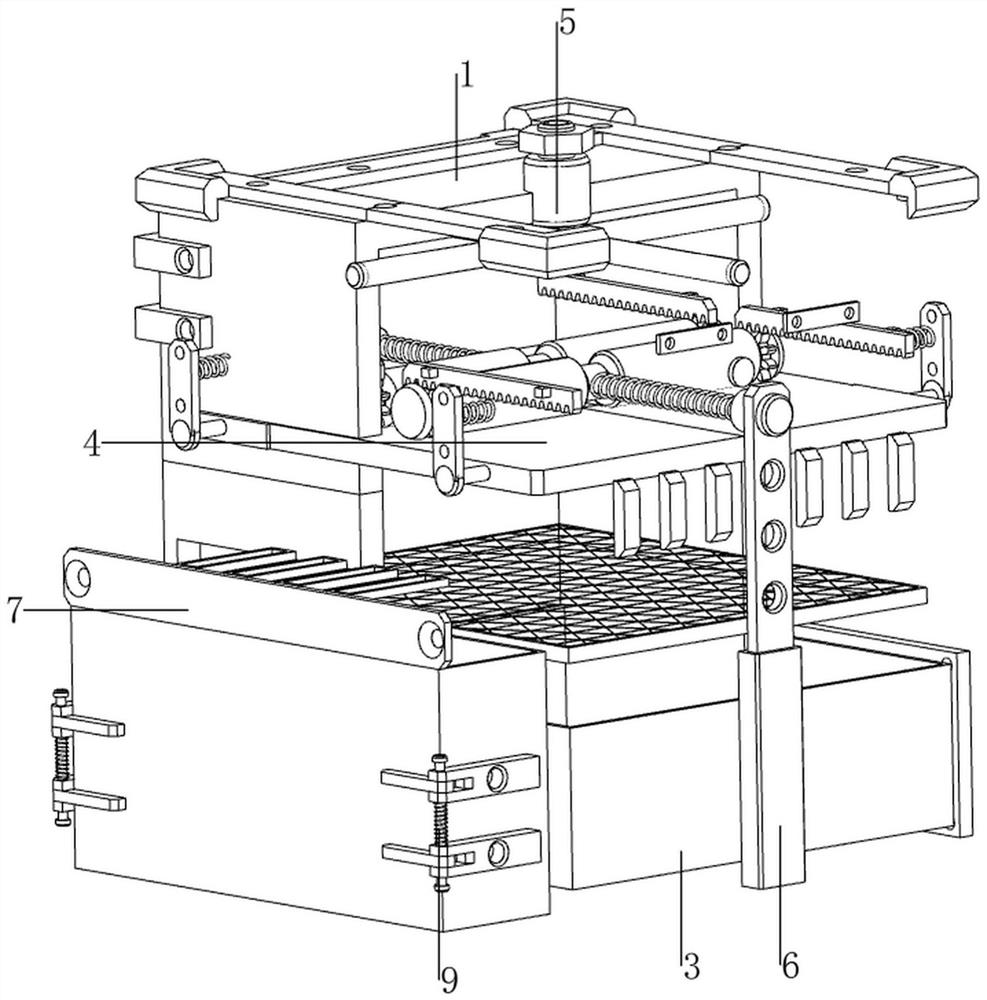

[0060] A needle tube processing device for anesthesia department, such as Figure 1-11 As shown, it includes a box body 1, a first collection frame 3, a discharge mechanism 4, a disinfection mechanism 5, and a crushing mechanism 6. The inner side of the left part of the box body 1 is slidingly provided with the first collection frame 3, and the upper side of the box body 1 A discharge mechanism 4 is provided, a disinfection mechanism 5 is provided on the top of the box body 1, the disinfection mechanism 5 is connected with the discharge mechanism 4, and a crushing mechanism 6 is provided on the box body 1.

[0061]People press the main switch of the power supply to power on the device, and then people pour the waste needle tubes on the part of the discharge mechanism 4 in the box body 1, the gravity of the waste needle tubes makes the disinfection mechanism 5 run, and the disinfection mechanism 5 sprays disinfectant on the needle tubes , so as to sterilize the needle tube, the...

Embodiment 2

[0069] On the basis of Example 1, such as Figure 1-3 and Figure 12-15 As shown, a screening mechanism 7 is also included. The screening mechanism 7 includes a screen 71, a second collection frame 72 and a second electromagnet 73. The lower part of the inner side of the casing 1 is provided with a screen 71, and the bottom of the right side of the casing 1 is sliding A second collection frame 72 is provided, and a second electromagnet 73 is provided on the upper left side of the second collection frame 72 , and the second electromagnet 73 cooperates with the screen 71 .

[0070] The crushed needle tube will drop down from the first electromagnet 41 and the magnetic plate 43 to the screen cloth 71 due to gravity, and the screen cloth 71 screens the crushed needle tube so that the metal needle is separated. In addition, when the distance sensor When the detection value of 67 reached the preset value in the control module, the control module would control the second electromagn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com