Piston type pneumatic motor for emergency rescue

An emergency rescue, air motor technology, applied in the direction of engine components, machines/engines, mechanical equipment, etc., can solve the problems of poor service life, affecting the rescue effect, poor motor stability, etc., to increase the stability of use, improve the use of Safety and the effect of improving the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

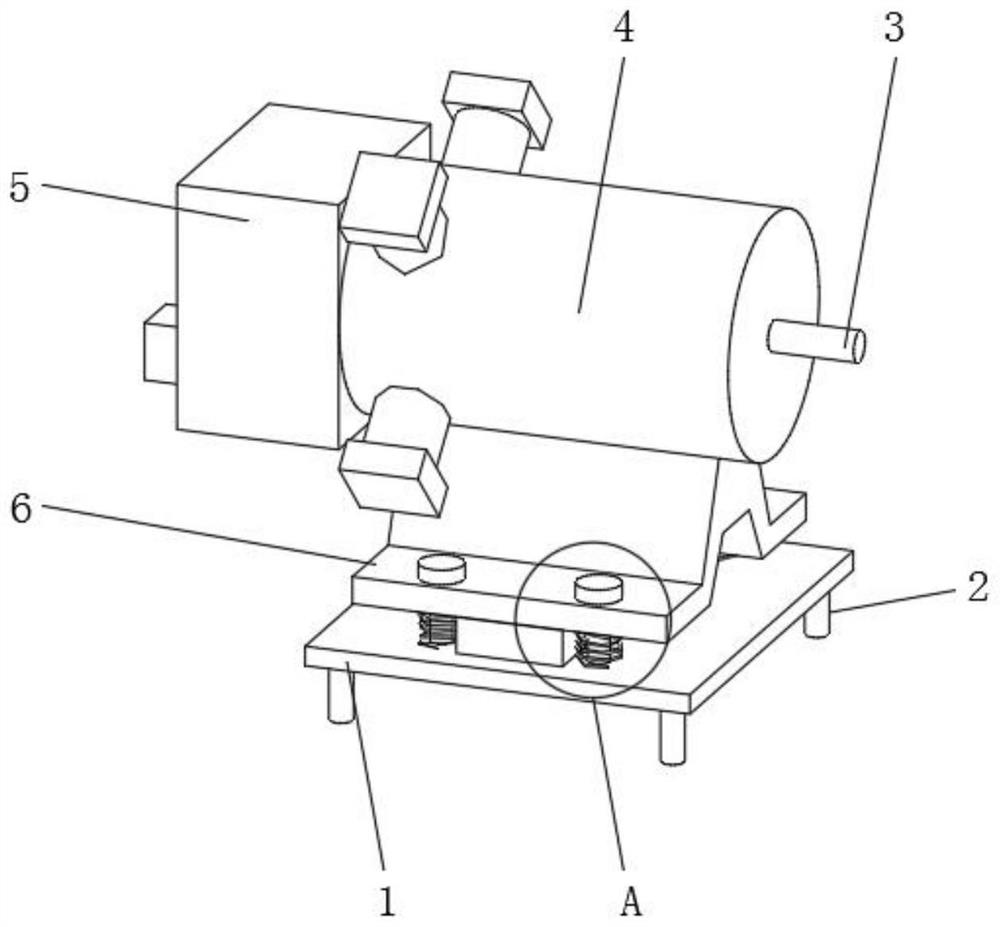

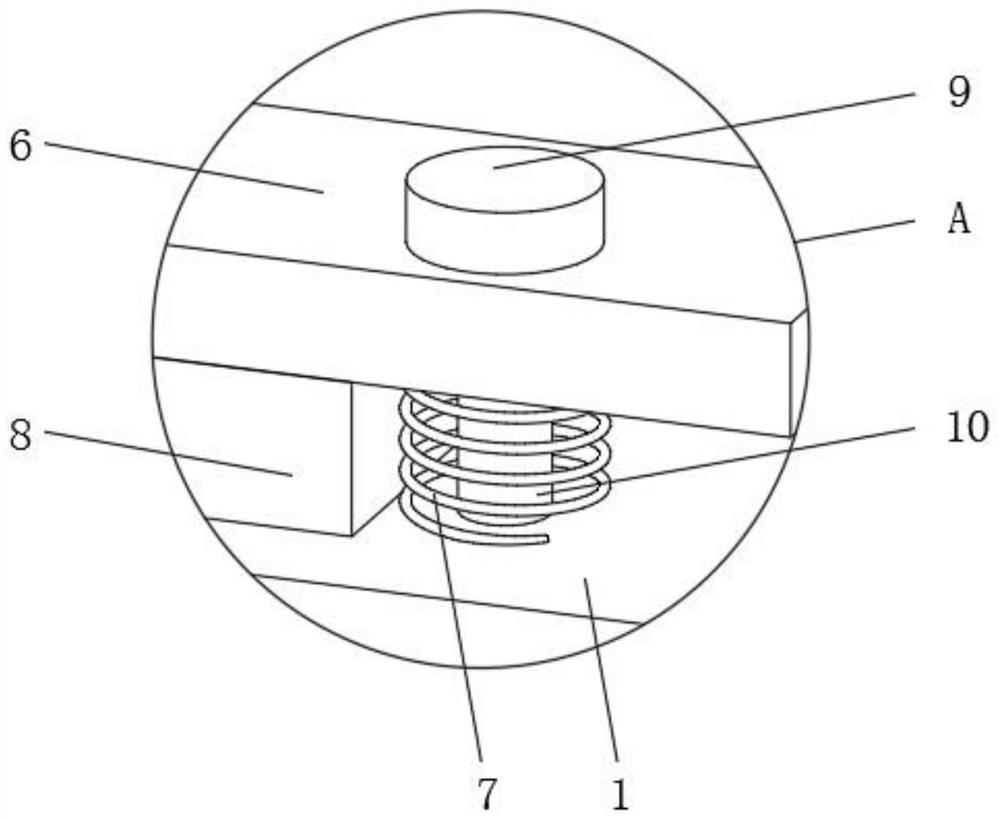

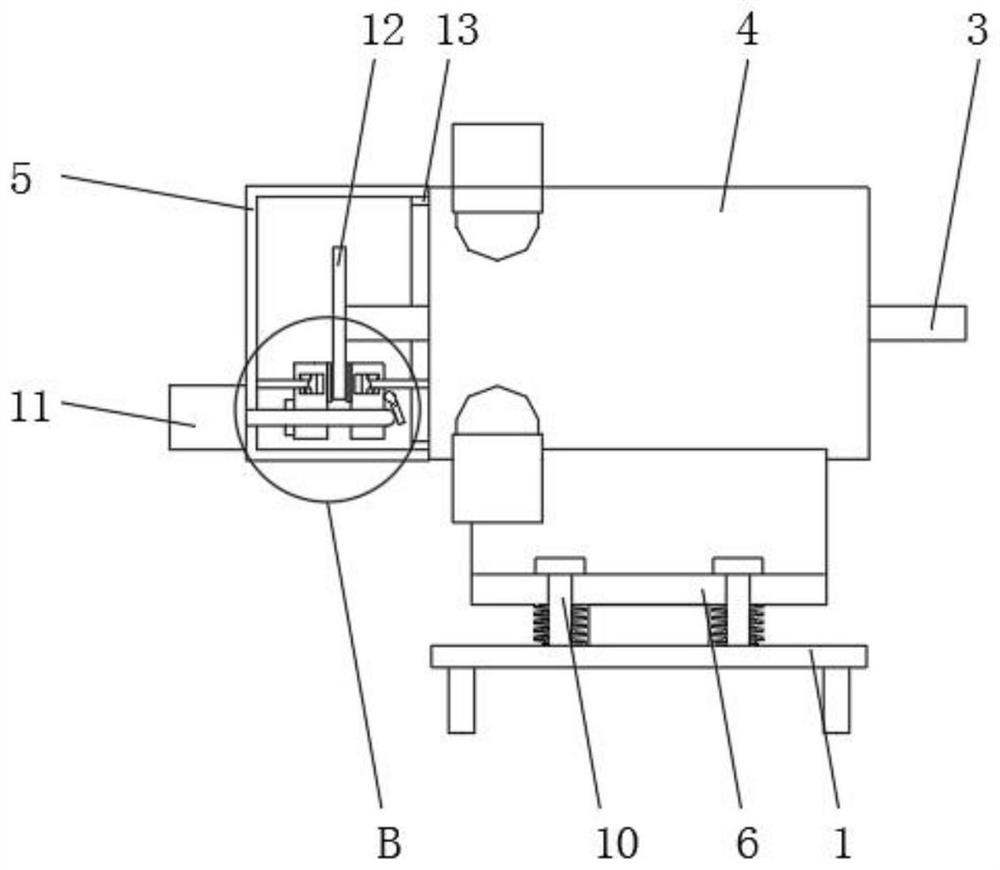

[0023] Such as Figure 1-4 As shown, in order to achieve the above object, the present invention provides the following technical solutions: a piston type air motor for emergency rescue, including a fixed seat 1 and a main body 4, buffer columns 10 are installed at the top four corners of the fixed seat 1, and the buffer column The outer surface of 10 is located on the top of the fixed seat 1, and the supporting seat 6 is installed. The main body 4 is installed on the top of the supporting seat 6, and the drive shaft 3 is installed in the middle of the main body 4. The outer surface of the buffer column 10 is located at the gap between the supporting seat 6 and the base. The spring 7, the top of the buffer column 10 is located on the upper surface of the support seat 6, and the spring seat 9 is installed on the upper surface. The rear cover 5 is installed on the side of the main body 4 through the connecting seat 13. One end of the drive shaft 3 is located inside the rear cover...

Embodiment 2

[0026] Such as Figure 1-4 As shown, the present invention proposes a piston-type air motor for emergency rescue. Compared with Embodiment 1, this embodiment also includes: the top of the fixing seat 1 near the middle of the front surface and the middle of the rear surface are equipped with rubber Seat 8, fixed column 2 is all installed at four corner positions of the bottom of fixed seat 1.

[0027] In this embodiment, before use, the present invention is quickly fixed by the fixing column 2. During use, the rubber seat 8 and the buffer spring 7 are used to buffer the vibration force of the main body 4 to increase the stability of the present invention.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com