Storage tank settlement inclination monitoring method and system

A monitoring system, storage tank technology, applied in directions such as measuring inclination, measuring device, mapping and navigation, and can solve problems such as personal hazards

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

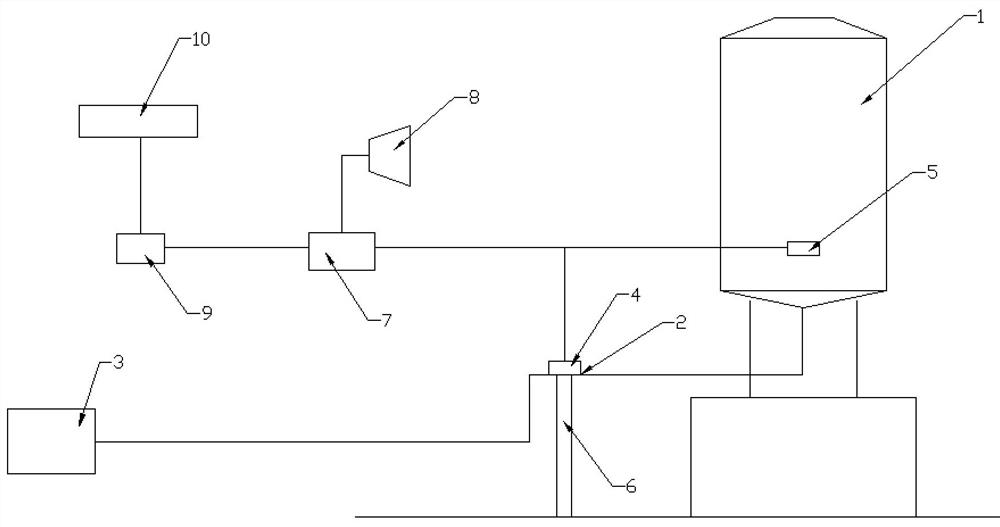

[0043] In order to further reduce the cost and improve the equipment reuse rate, embodiment 1 is as figure 2 As shown, a way of installing the attitude sensor I4 on the existing process pipeline 2 is provided. The existing storage tank 1 is provided with a process pipeline 2; one end of the process pipeline 2 is connected with a filling device 3, and the other end of the process pipeline 2 is connected with the storage tank 1, and at least a part of the process pipeline 2 is used as the The support member 100, the attitude sensor I4 is arranged on the horizontal section of the process pipeline 2. In this embodiment, the storage tank 1 is installed horizontally, and its process pipeline 2 is horizontally connected to it. Using the process pipeline 2 as the support 100 to install the attitude sensor 14 saves the cost of the support.

[0044]In order to allow the position of the attitude sensor I4 to remain unchanged from the ground and the angle can change with the change of ...

Embodiment 2

[0047] Example 2 as image 3 As shown, the difference from Embodiment 1 is that in this embodiment, the storage tank 1 is installed vertically, and the connection between the process pipeline 2 and its connection is vertical, but there is still a horizontal section behind the process pipeline 2, so the attitude sensor 14 is installed The purpose of the invention can also be realized in the horizontal section. The rest of the structures and determination methods are the same as those in Embodiment 1, and will not be repeated here. It should be noted that in this embodiment, the vertical section of the process pipeline connected to the storage tank 1 is regarded as a part of the storage tank.

[0048] In addition, the attitude sensor of the present invention may be an angle sensor, and of course other sensors capable of sensing angle changes may also be used.

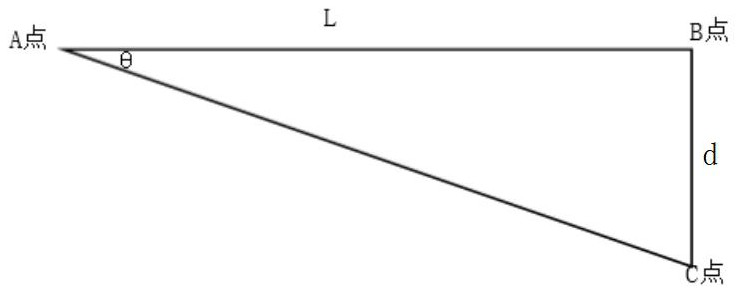

[0049] Such as Image 6 As shown, the present invention also provides a method for monitoring the settlement and inc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com