Waterproof method of electronic equipment and electronic equipment

A technology for electronic equipment and areas, applied in the direction of electrical equipment shell/cabinet/drawer, electrical components, sealed shell, etc., can solve the problem of poor waterproof performance of mobile terminals, ensure the strength, improve the reliability of the whole machine, and ensure the back glue The effect of width requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

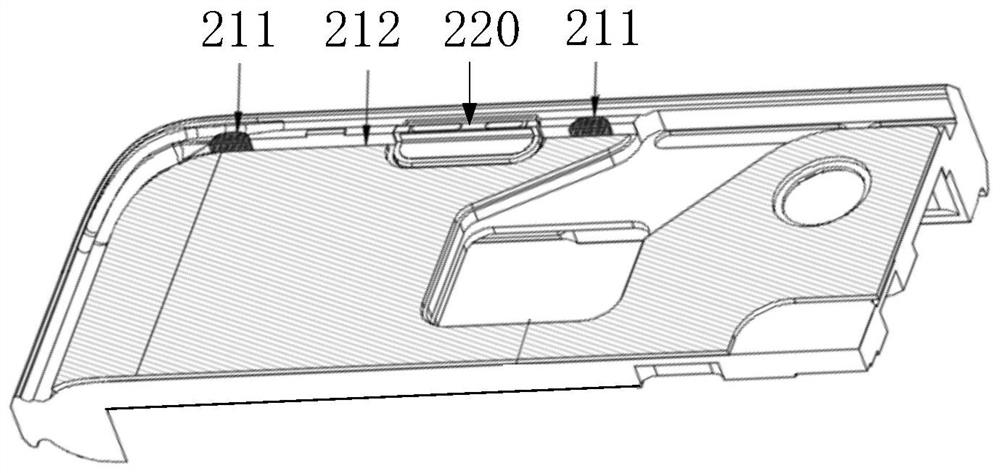

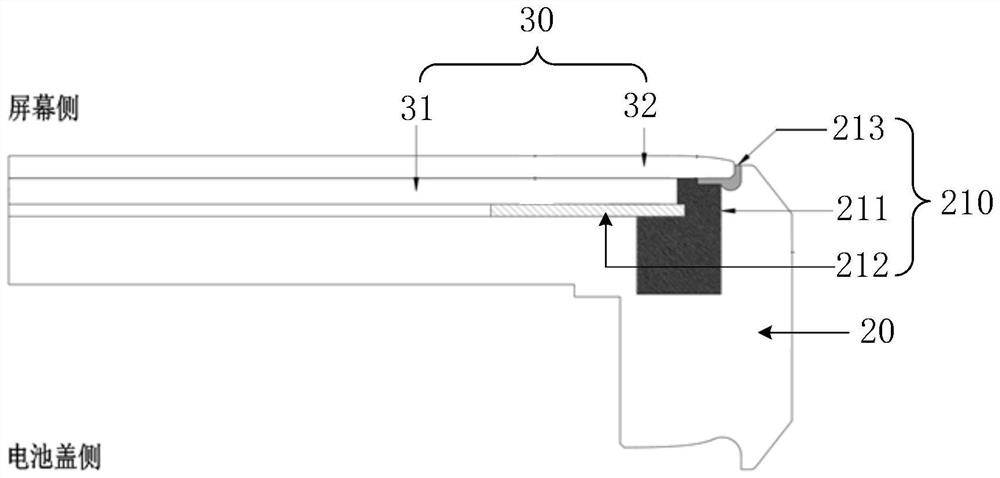

[0058] Example 1, such as image 3 as shown, image 3 It shows a partial cross-sectional view of the bonded state of the middle frame 20 and the screen module 30. The left side of the figure is the central area close to the middle frame, and the right side is the edge area of the middle frame. image 3 Among them, the back glue 212, the solid hot melt glue 211 and the dispensing body 213 are arranged from left to right (that is, the center of the middle frame is arranged in sequence toward the edge of the middle frame).

example 2

[0059] Example 2, combined with Example 1, the adhesive can be pasted on the left side of the solid hot melt adhesive, and the dispensing body can be fixed on the right side of the solid hot melt adhesive.

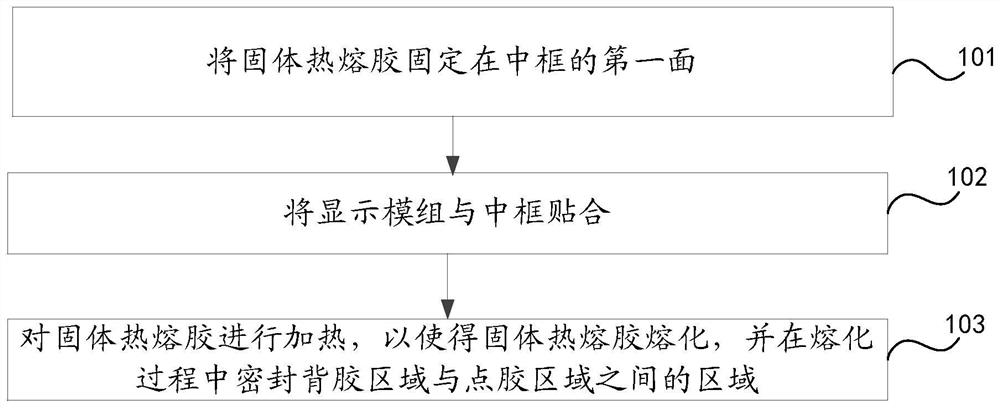

[0060] The method for waterproofing electronic equipment provided by the embodiment of the present application can fix the solid hot melt adhesive on the first surface of the middle frame; then attach the display module to the middle frame; and then heat the solid hot melt adhesive so that the solid heat The adhesive melts and in the process seals the area between the adhesive backed area and the dispensed area. Among them, the adhesive area is pasted with adhesive, and the dispensing area is filled with a little glue; the dispensing area is set around the adhesive area on the middle frame. Therefore, this waterproof method does not need to open glue holes on the middle frame, which ensures the structural strength of the middle frame and improves the reliability of the ele...

example 3

[0073] Example 3, combined with Example 2, refer to image 3 , the left side of the back glue 212 is pasted on the middle frame, and the right side is pasted with the first area of solid hot melt adhesive.

[0074] In this way, by partially covering the back glue on the first area of the solid hot melt adhesive, the partial overlap of the back glue and the solid hot melt adhesive can better fix the solid hot melt adhesive on the middle frame, and in the solid heat After the melt glue is melted, there is an overlapping area between the solid hot melt glue and the back glue, which improves the waterproof performance.

[0075] Optionally, in this embodiment of the present application, after step 101 and before step 102, step 105 is also included.

[0076] Step 105, performing glue dispensing on the glue dispensing area of the middle frame.

[0077] Exemplarily, a glue dispensing body may be used to directly perform glue dispensing on the above glue dispensing area.

[00...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com