Automatic snow cleaning device for power equipment

A power equipment, automatic cleaning technology, applied in the substation/distribution device casing, heating device, lighting and heating equipment, etc., to achieve the effect of convenient retraction and improvement of cleaning efficiency and effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

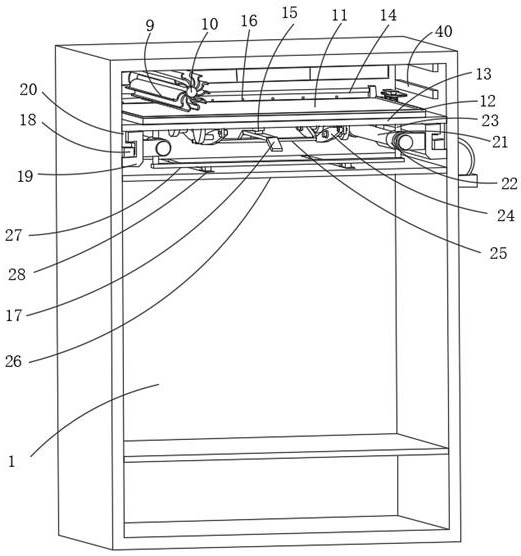

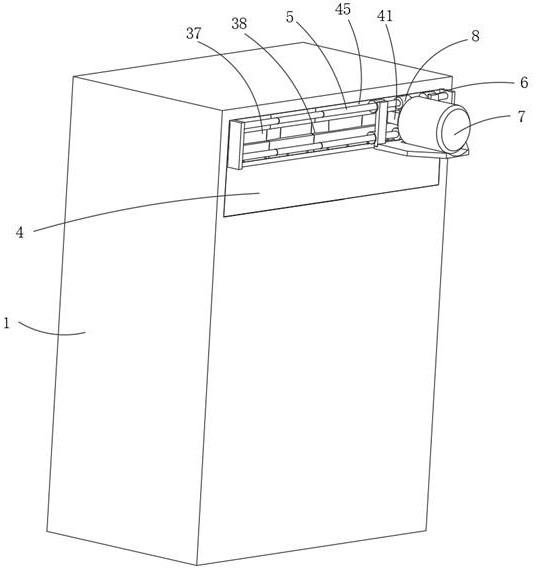

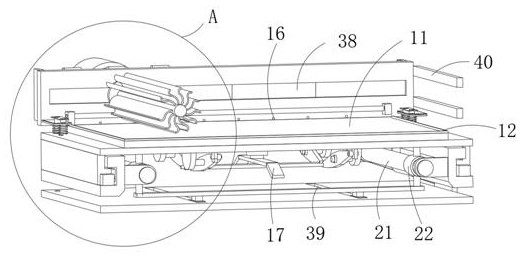

[0032] like figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Image 6 , Figure 7 , Figure 8As shown, this embodiment proposes an automatic snow removal device for electric power equipment, including a power equipment cabinet 1, a sealing plate 26 is fixedly installed on the inside of the power equipment cabinet 1, a support plate 13 is movably installed on the inside of the power equipment cabinet 1, and the support plate One end of 13 is fixedly connected with a backboard 4, the upper surface of the backboard 4 is movably provided with a load-bearing plate 3, and one end of the load-bearing plate 3 is equipped with a snow clearing mechanism, which includes a swing opening 37 provided on the load-bearing plate 3, and The swinging block 41 slidingly installed with the load-bearing plate 3, the inside of the swinging block 41 is interspersed and rotated to install the rotating shaft 10, the outer surface of the rotating shaft 10 is provided with snow-clearing sh...

Embodiment 2

[0034] The scheme in embodiment 1 is further introduced below in combination with specific working methods, see the following description for details:

[0035] like figure 1 , Figure 4 , Figure 5 , Image 6 As shown, as a preferred embodiment, on the basis of the above method, further, the sliding mechanism includes a chute 19 fixedly installed on the two inner walls of the power equipment cabinet 1, and a sliding plate 20 slidably connected to the inner side of the chute 19. The adjacent sides of each slide plate 20 are all fixedly connected with the support plate 13, and the inner side of the chute 19 is fixedly connected with a stopper 18, and the slide plate 20 slides in the chute 19, so that the slide plate 20 drives the support plate 13 to move, and the stopper 18 Blocking it facilitates the installation and disassembly of the snow removal device and facilitates maintenance.

[0036] like figure 1 , Figure 4 , Figure 5 , Image 6 , Figure 8 As shown, as a p...

Embodiment 3

[0041] The schemes in Embodiment 1 and Embodiment 2 are further introduced below in conjunction with specific working methods, see the following description for details:

[0042] Specifically, when the automatic snow removal device for electric power equipment is working: the personnel first lifts the clamping plate 32, thereby driving the clamping rod 33 to lift and compress the spring 31, so that the clamping rod 33 is separated from the through hole 30, and then pushes up the push frame 27 so that Drive the cover block 22 to move to one end on the fixed rod 21, thereby driving the through rod 36 to pull the slide plate 20 to slide in the chute 19, so that the slide plate 20 drives the support plate 13 to move, thereby driving the load bearing plate 3 and the back plate 4 to move, so that the cleaning The snow mechanism, the drainage mechanism, the jacking mechanism, and the pushing mechanism move out of the power equipment cabinet 1 at the same time. After moving out, the pe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com