A two-way double-acting oil cylinder

A double-acting oil cylinder and oil cylinder technology, which is applied in the direction of fluid pressure actuating devices, can solve the problems of increasing the axial size of the oil cylinder, etc., and achieve the effects of reducing the number of collisions, easy extension, and prolonging the fatigue life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

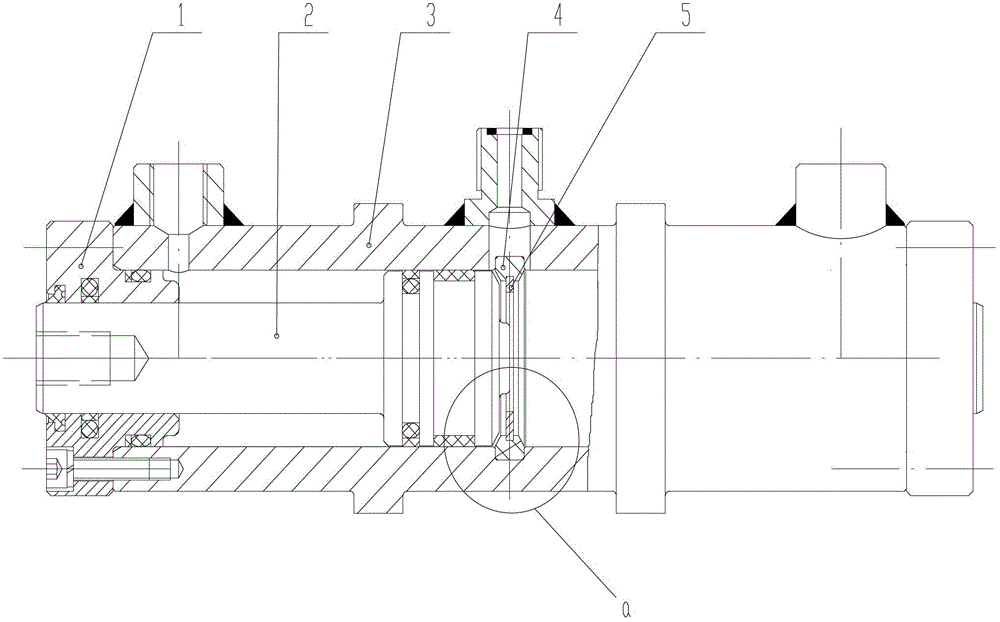

[0021] The specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings.

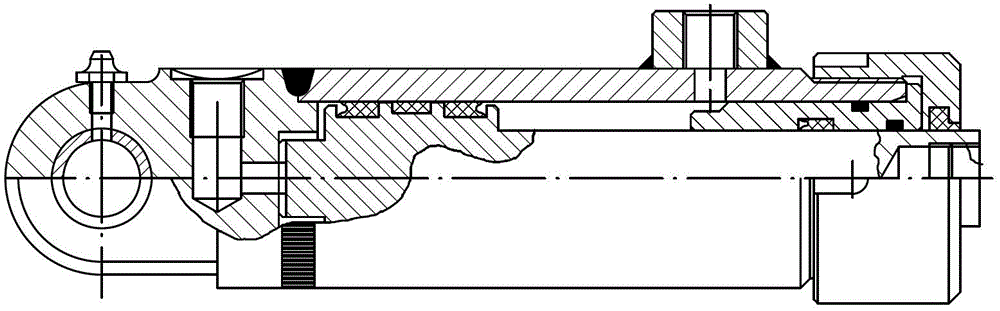

[0022] like figure 2 The embodiment shown is a two-way double-acting oil cylinder, which includes two cylinder barrels 3 whose bottom ends are butted, a cylinder head 1 arranged at the top of the cylinder barrel 3, and a piston 2 arranged in the cylinder barrel 3. The two cylinders 3 are connected, and the inner wall of the bottom end is provided with a limit card key 4, and each corner of the limit card key 4 is rounded; a circlip 5 is arranged on the top of the limit card key 4, In the case of a total length of 230mm, the telescopic strokes S of the pistons at both ends are each 50mm.

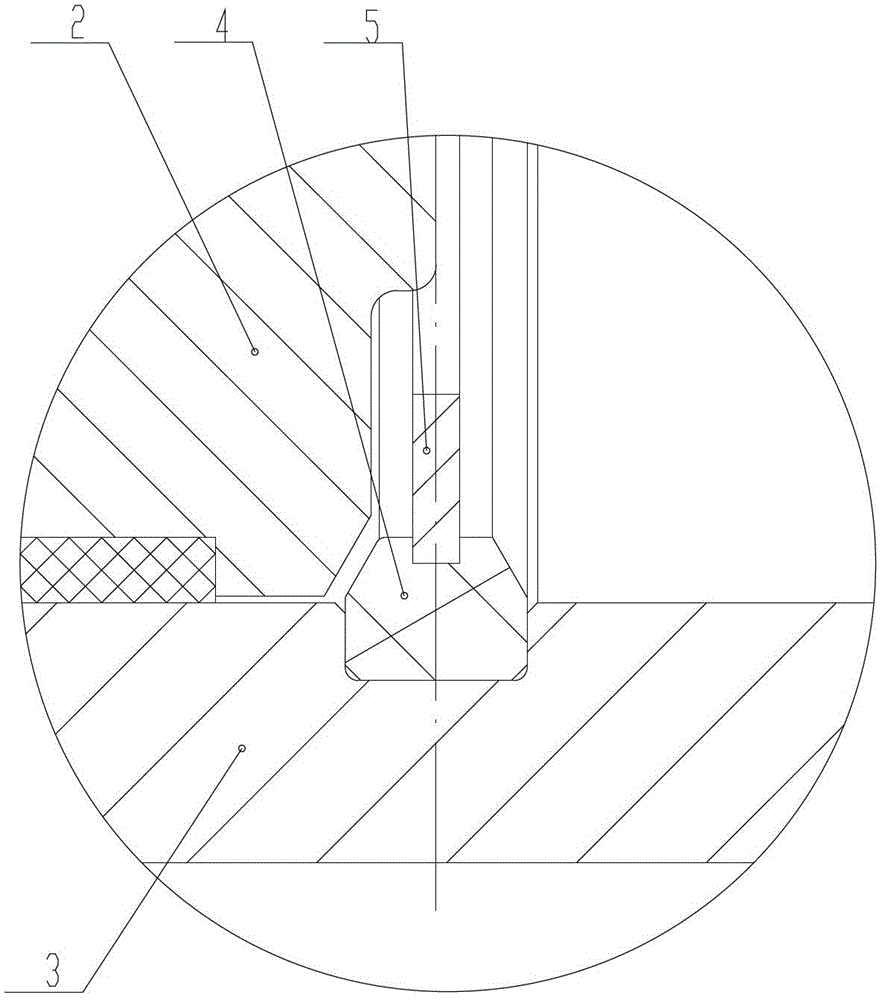

[0023] like image 3 In the shown embodiment, the limit snap key 4 is in the shape of an annular or partially annular protrusion, which has an inclined surface in contact with the piston 2, and the inclined angle of the inclined surf...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com