Adjustable and efficient chemical raw material rinsing device for chemical production

A technology for chemical raw materials and chemical production, which is applied in cleaning methods and utensils, chemical instruments and methods, and cleaning methods using liquids, etc., can solve the problems of inconvenient separation, inconvenient adjustment, inconvenient disassembly and assembly, and achieve the effect of increasing the effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

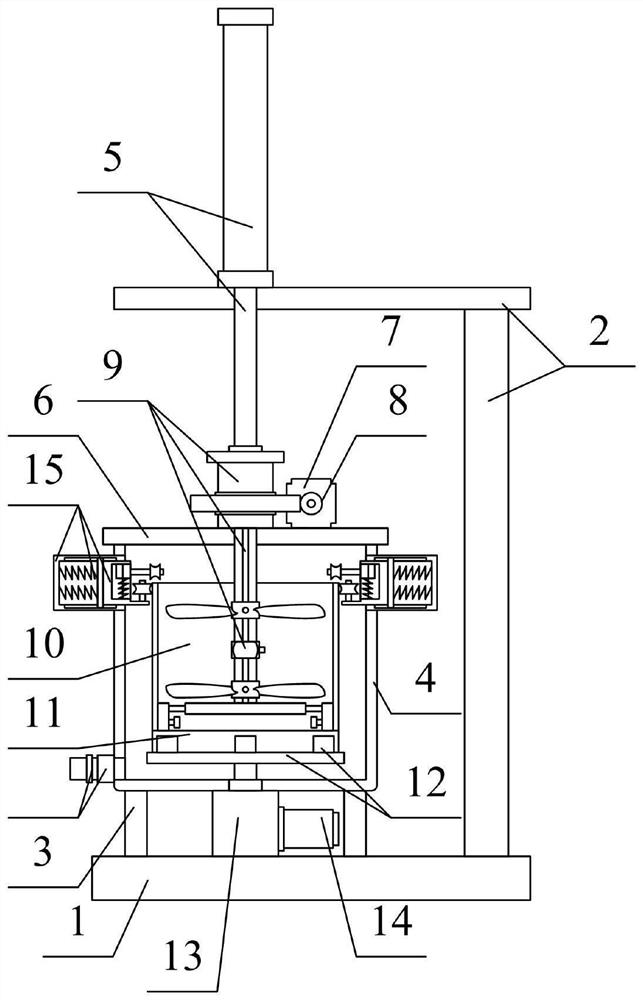

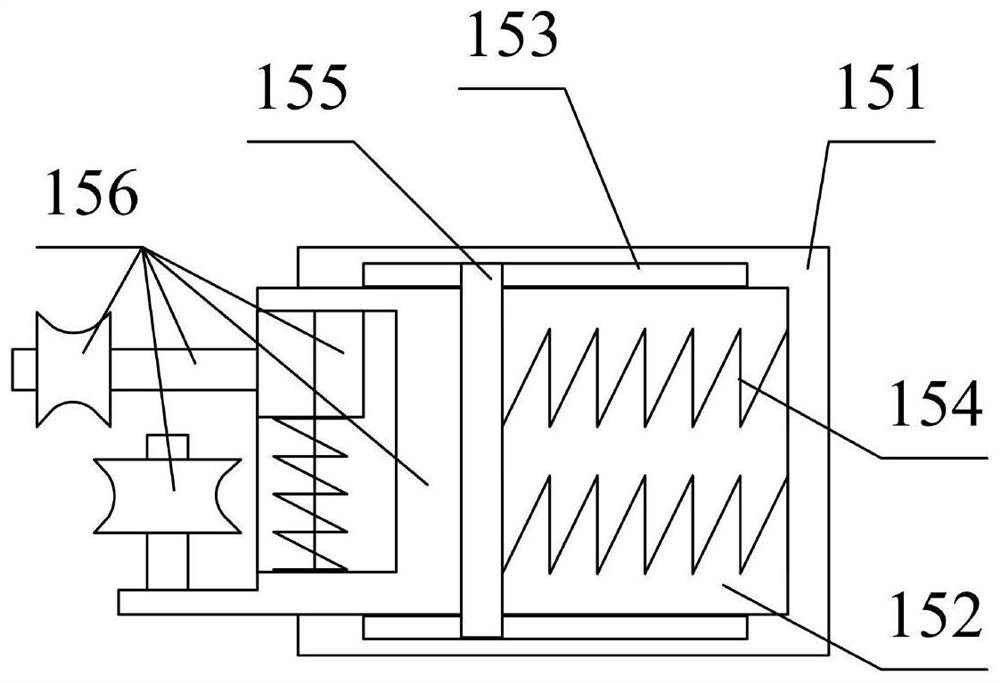

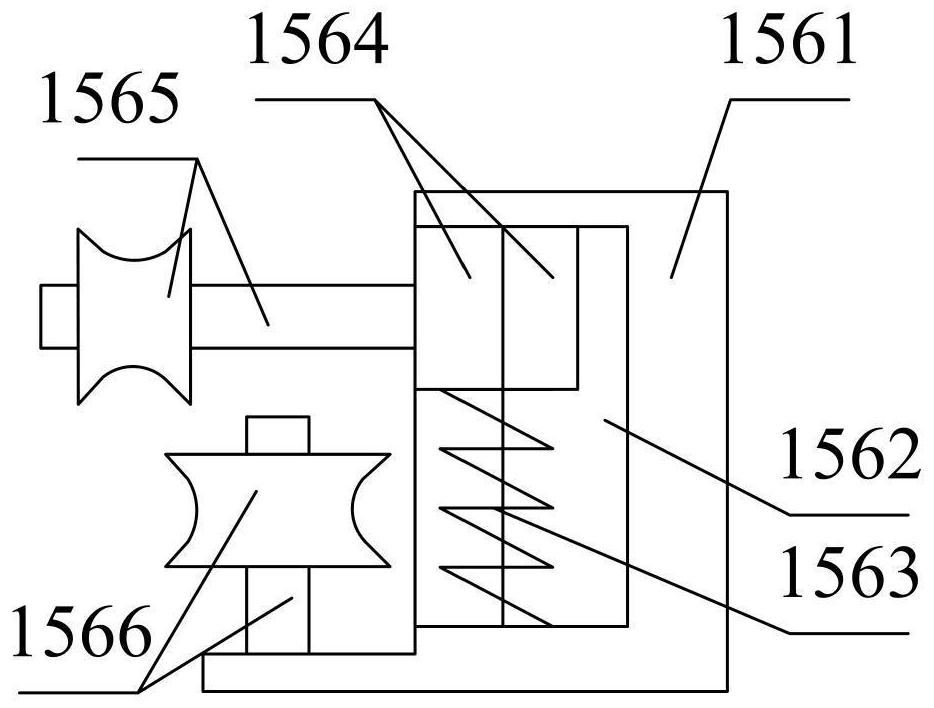

[0029] as attached figure 1 As shown, an adjustable and efficient chemical raw material rinsing device for chemical production includes a base 1, a bracket 2, a pole 3, a barrel body 4, a lifting electric cylinder 5, a sealing cover plate 6, an agitating motor 7, and a worm 8 , rotate and adjust the vertical bar structure 9, the net tube 10, the docking platform 11, the rotating platform 12, the gear box 13, the rotating motor 14 and the side frame structure 15 for removal and stabilization, the right side of the upper end of the base 1 is welded with a support 2, and The lifting electric cylinder 5 is installed on the left bolt on the upper end of the bracket 2; the bolts of the support rod 3 are installed between the base 1 and the barrel body 4; , and the sealing cover plate 6 is clipped on the outer wall of the rotation adjustment vertical rod structure 9; the stirring motor 7 bolts are installed on the right side of the upper end of the sealing cover plate 6, and the outp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com