Processing equipment for chemical pressure vessel

A pressure vessel and processing equipment technology, which is applied in the field of chemical pressure vessel processing equipment, can solve the problems of long replacement time, affecting the working efficiency of the device, cumbersome manual replacement, etc., and achieve the effect of improving the use effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

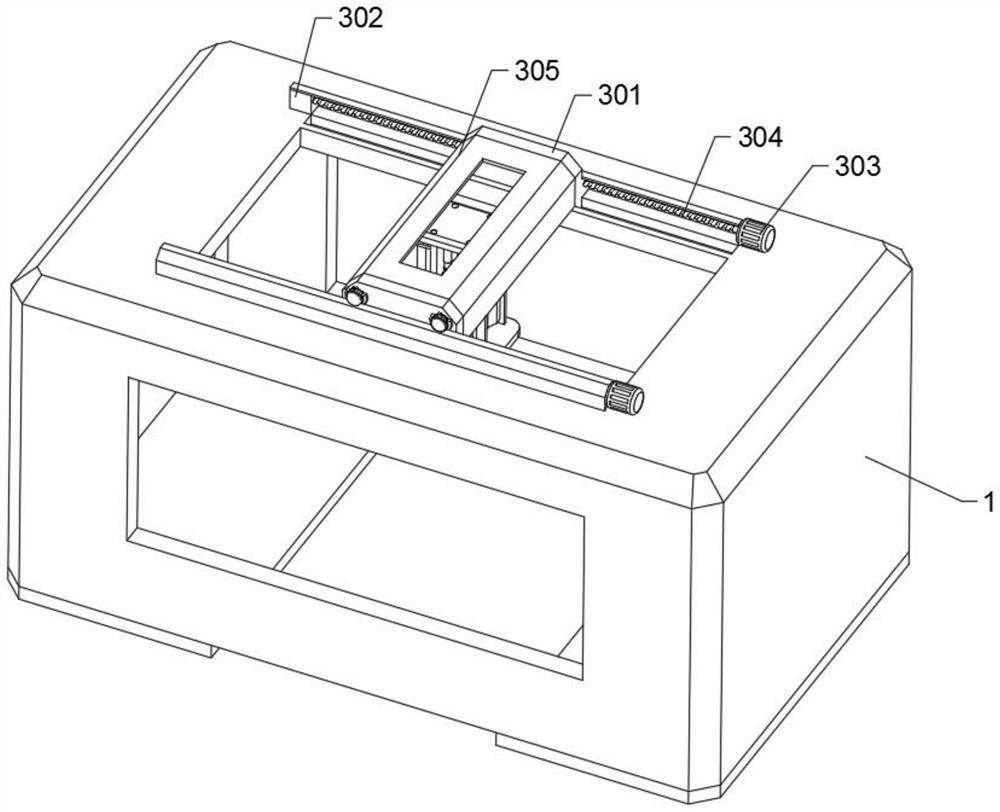

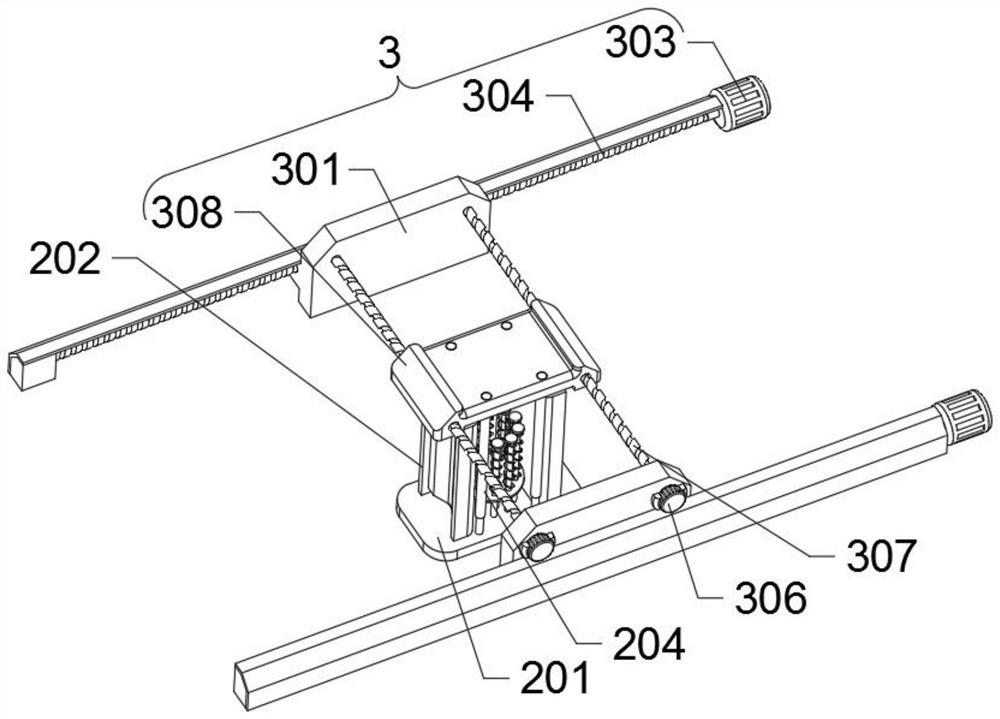

[0020] Example 1, such as Figure 1-3 As shown, the present invention provides a processing equipment for chemical pressure vessels, which includes a housing 1 , an adjustment mechanism 3 is fixed on the top of the housing 1 , and a punching mechanism 2 is fixed on the bottom of the adjustment mechanism 3 .

[0021] Let's talk about the specific setting and effect of its punching mechanism 2 and regulating mechanism 3 in detail below.

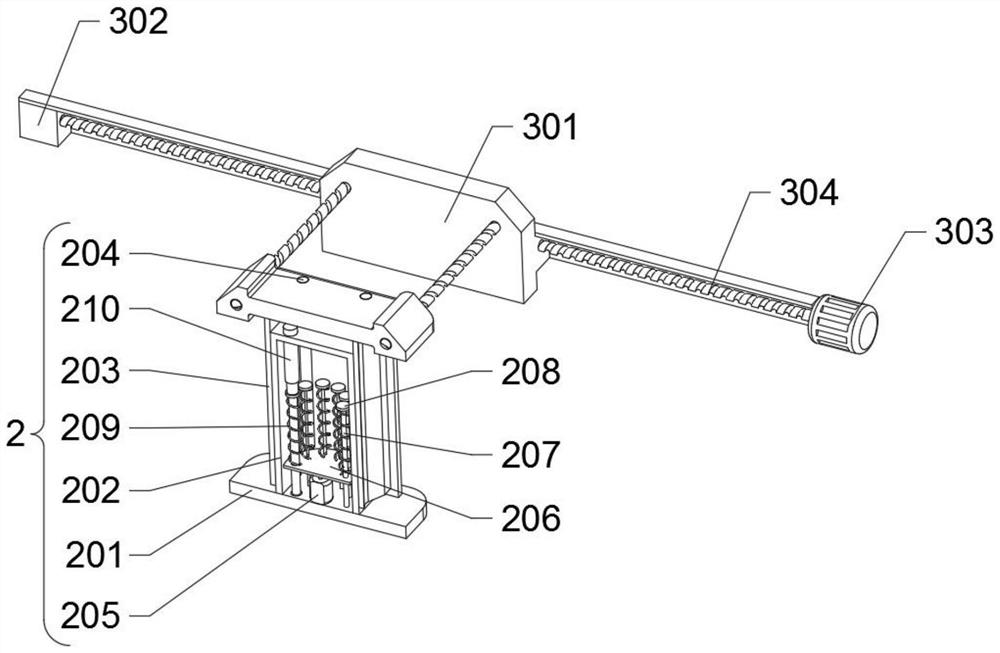

[0022] like Figure 2-3 As shown, the punching mechanism 2 includes a support plate 201, the top of the support plate 201 is fixed with a U-shaped plate 202, both sides of the U-shaped plate 202 are provided with limiting plates 203, and the top four corners of the support plate 201 are fixed with Adjust the telescopic rod 204, the top center of the support plate 201 is fixed with an adjustment motor 205, the output shaft of the adjustment motor 205 is fixed with a fixed plate 206, the fixed plate 206 is provided with eight punching rods 207, ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap