Automatic press riveting equipment and press riveting jig for notebook computer pivot device

The technology of a pressure riveting fixture and a hinge device is applied in the field of riveting and pressing equipment, which can solve the problems of riveting pressure and slow riveting speed of the hinge device with a small scope of application and cannot be of different specifications, and achieves the effect of a large application range.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

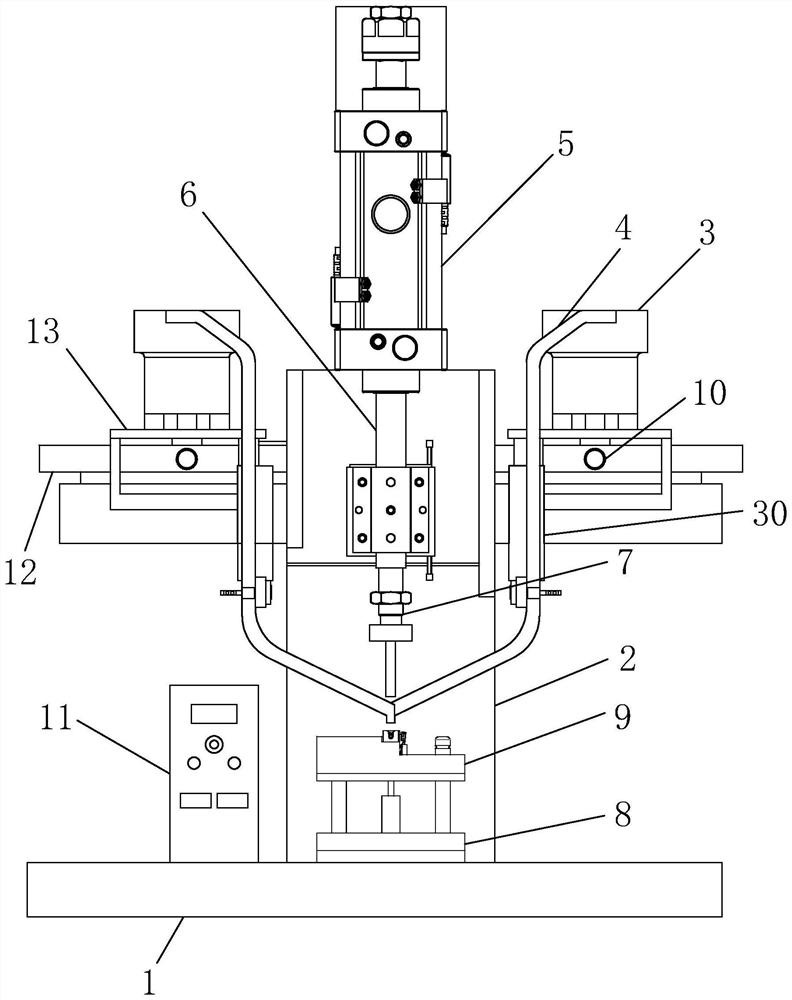

[0041] as Figures 1 to 6 As shown, a notebook hub 19 automatic riveting equipment and riveting fixtures, comprising:

[0042] Machine 1, the machine 1 is provided with an organic frame 2; the pressure riveting fixture carried in the machine 1 for fixing the hub 19; the pressure riveting mechanism carried on the machine 19 for riveting the hub 19; and the pitch adjustment component disposed in the fixing frame 12 for adjusting the movement of the outfeed component before and after.

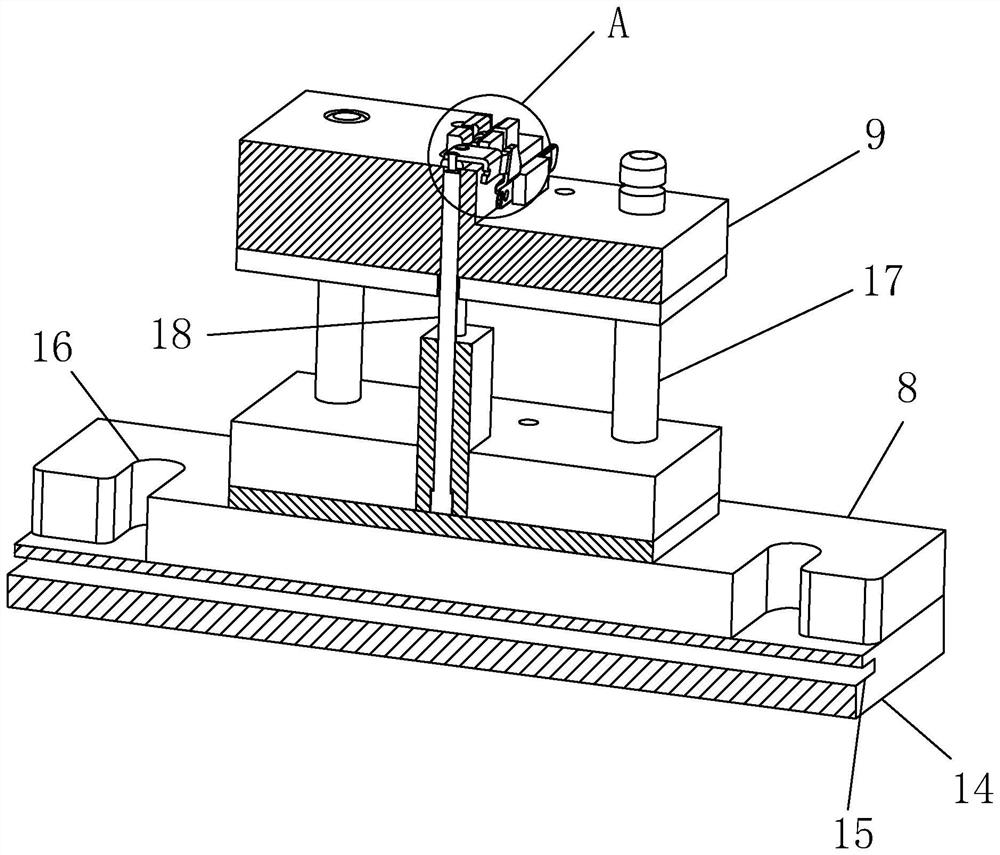

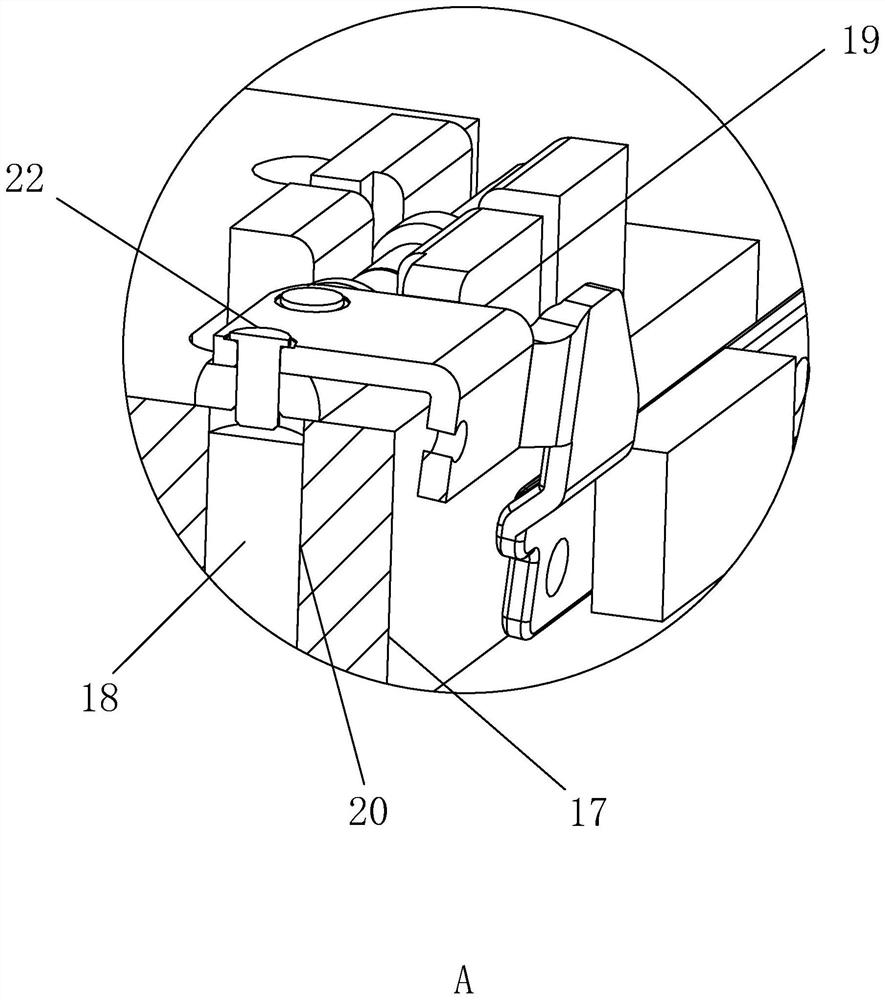

[0043] Specifically, the pressure riveting fixture comprises: a mount 14 disposed on the machine 14, a removable lower die base 8 disposed on the mount 14, and a fixed die 9 disposed in the lower mold base 8, wherein the hub 19 is disposed in the fixed die 9, the hub 19 is opened before and after two sets of riveting holes through its thickness, the riveting hole is used to place rivets 22; the pressure riveting mechanism comprises: a fixed frame 12 on both sides of the frame 2, two groups of vibrating...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com