Building vacuum insulated panel and manufacture method thereof

A technology of a vacuum insulation panel and a manufacturing method, which are applied to building components, insulation improvement, climate change adaptation, etc., can solve the problems of high production cost of vacuum insulation panels, damage to vacuum insulation bags, low production efficiency, etc., to save labor costs, The effect of increasing strength and saving construction costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

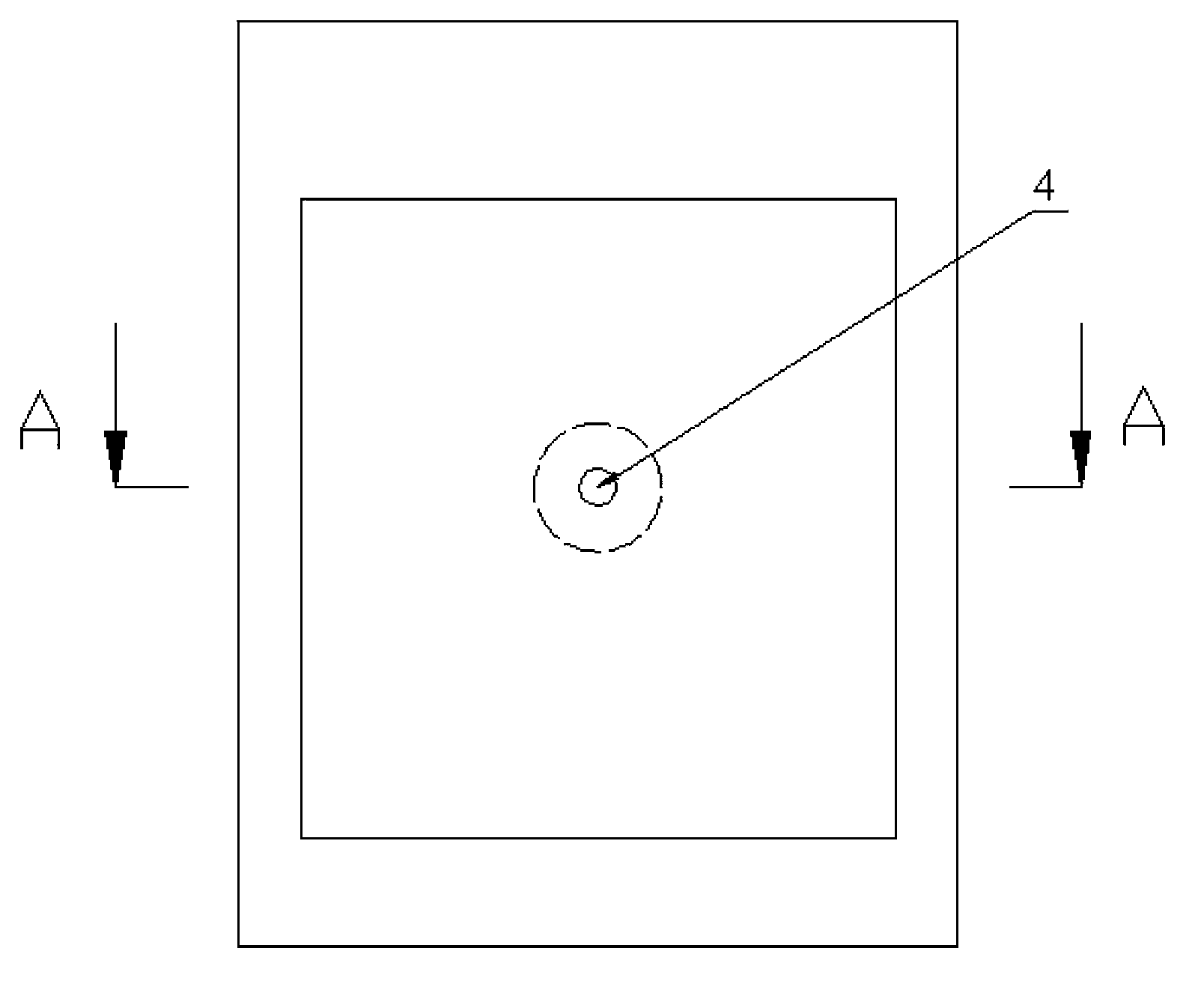

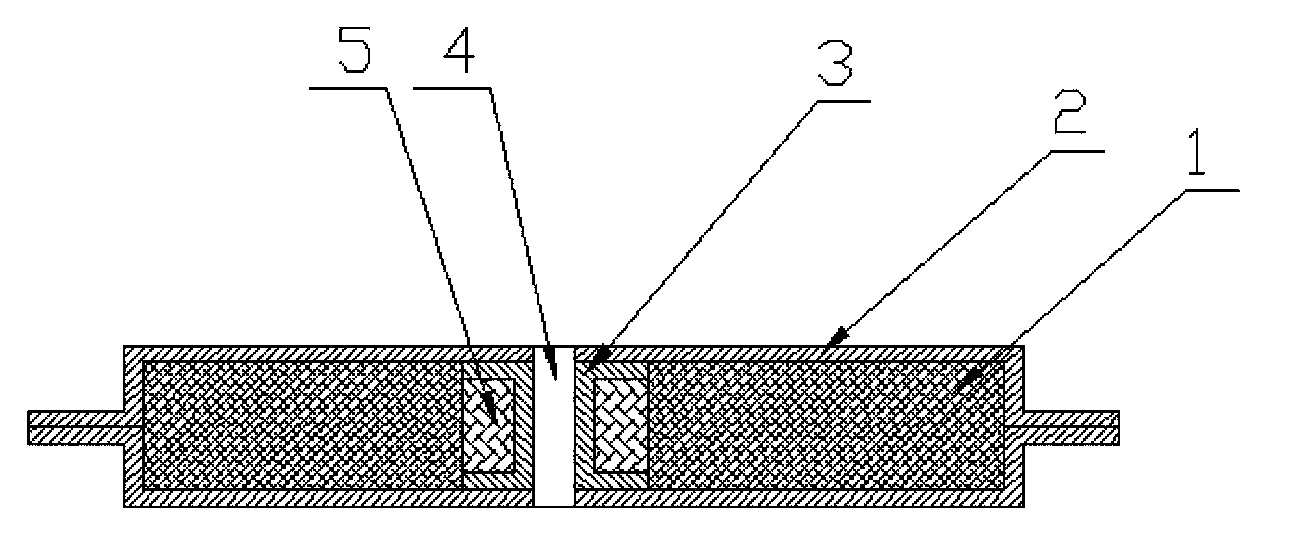

[0029] Embodiment: A vacuum insulation panel for building, comprising a core board 1, an air-tight high barrier film 2 and an air-absorbing cushion block 3. At least one perforation is formed on the core board 1, and an annular air-absorbing pad is arranged in the perforation. The air cushion block 3, the core plate 1 is sealed and wrapped by the barrier film 2 and the air-absorbing cushion block 3, and the anchor hole 4 is formed on the inner side of the air-absorbing cushion block. For anchoring installation, the head of the anchoring nail is supported by the suction pad, the barrier film 2 is not easy to be torn during anchoring, which effectively improves its anchoring strength. Will be destroyed, ensuring its excellent thermal insulation properties.

[0030] The structure in which the core board 1 is sealed and wrapped by the barrier film 2 and the air suction pad 3 is as follows: the barrier film 2 is provided with an opening consistent with the inner hole of the suction...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com