Grooving equipment for bearing adapter sleeve

A technology for slotting equipment and adapter sleeves, which is applied in metal processing equipment, measuring/indicating equipment, metal processing machinery parts, etc., and can solve the problems of uneven opening positions and inaccurate slot opening of bearing adapter sleeves, etc. , to achieve the effect of improving the slotting precision, improving the accuracy and realizing the positioning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

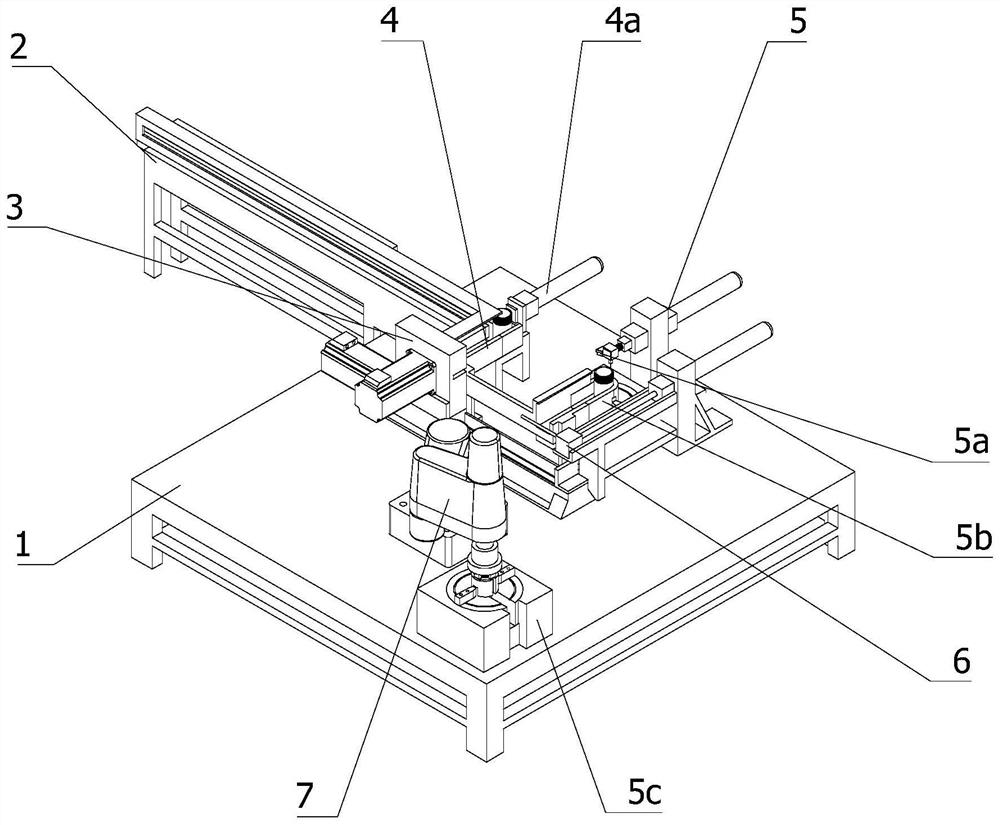

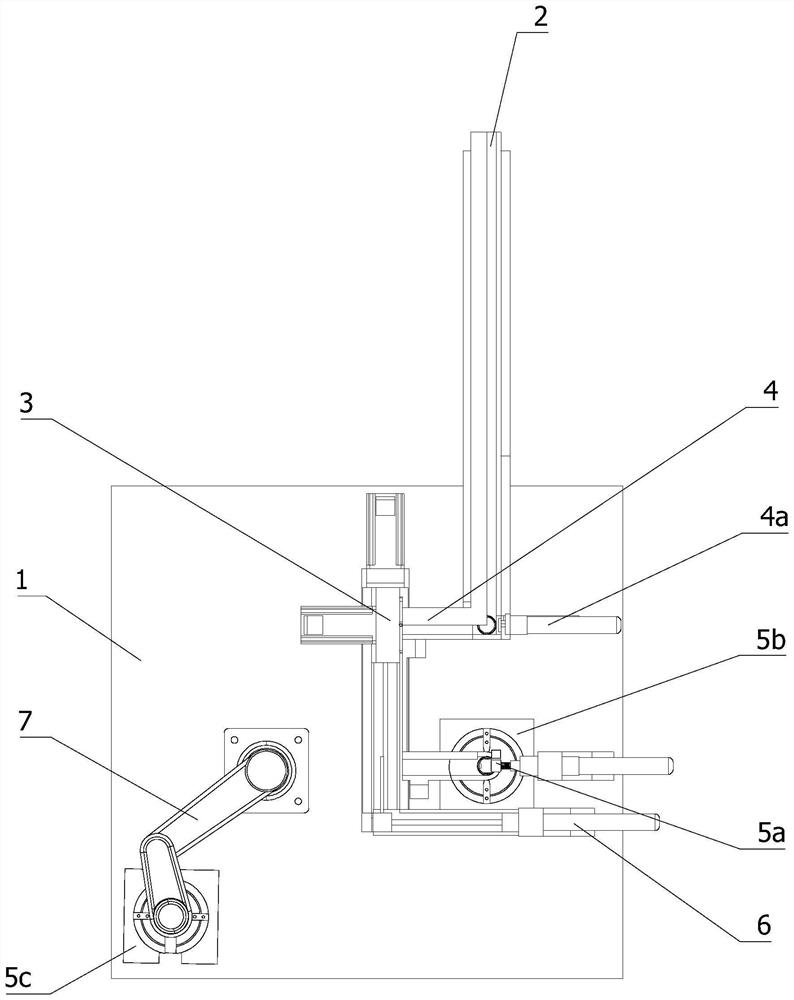

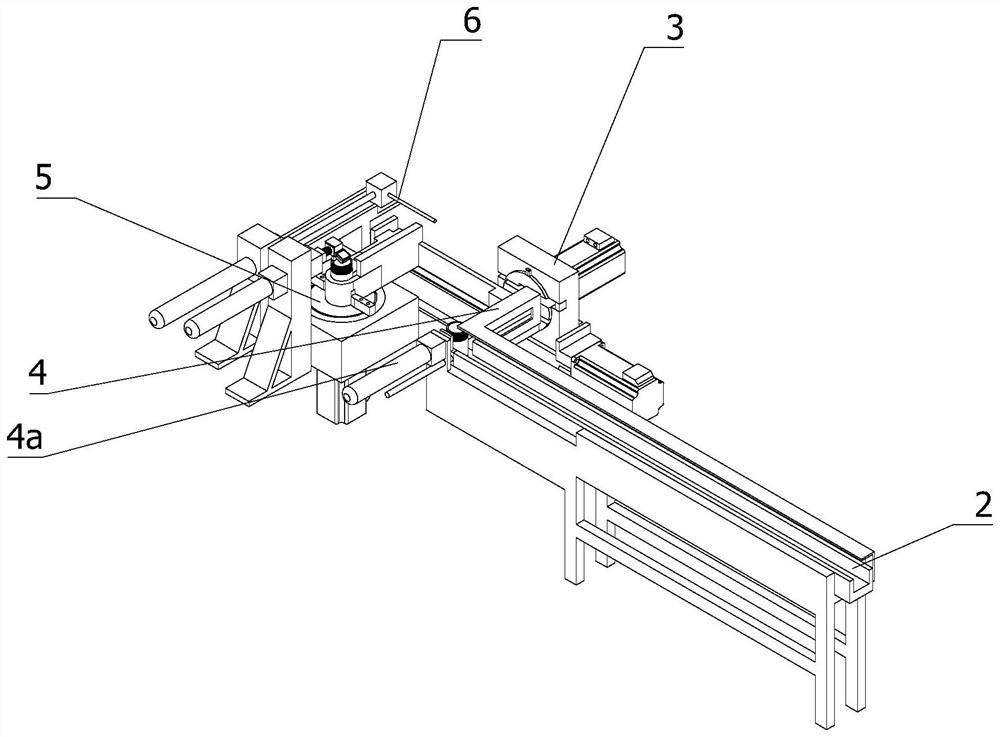

[0050] Such as Figure 1 to Figure 18 As shown, a slotting device for a bearing adapter sleeve in this embodiment includes a vibration track 2 arranged on a workbench 1 for transporting a bearing adapter sleeve 2a, and a vibrating track 2 is provided on the side of the output end of the vibration track 2. In order to ensure the conversion device 3 with the threaded end of the bearing adapter sleeve 2a facing upwards, a push track 4 is provided between the conversion device 3 and the output end of the vibration track 2, and a push track 4 is provided on the vibration track 2 to push the bearing adapter sleeve 2a is pushed to the push cylinder 4a on the conversion device 3 through the push rail 4, and a positioning detection device 5 for locating the bearing adapter sleeve 2a and detecting the starting point of its thread is provided on the side of the conversion device 3, the positioning detection device 5 includes a visual inspection mechanism 5a set on the workbench 1, a firs...

Embodiment 2

[0062] Compared with embodiment 1, in this embodiment, if Figure 4 to Figure 7 As shown: the conversion device 3 includes a mounting block 3a and a turntable 3b rotatably arranged on the mounting block 3a, the mounting block 3a is provided with a second rotary driver 3a1 for driving the turntable 3b to rotate, and the mounting block 3a can move toward Moving in the direction of the first fixture 5b, there is also a screw slide 3c on the workbench 1 for driving the installation block 3a to move, and a side of the turntable 3b facing the push track 4 is provided with a bearing adapter sleeve 2a to push in. The bayonet 3b1, the mounting block 3a is equipped with a second camera 3a2 whose output end is facing the side of the turntable 3b, and one side of the bayonet 3b1 is also provided with an observation port for the second camera 3a2 to observe the bearing adapter sleeve 2a 3b2.

[0063] The technical problem to be solved in this embodiment is how to place the bearing adapter...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com