Friction stir welding device and friction stir welding method

A technology of friction stir and joining devices, applied in welding equipment, metal processing equipment, manufacturing tools, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

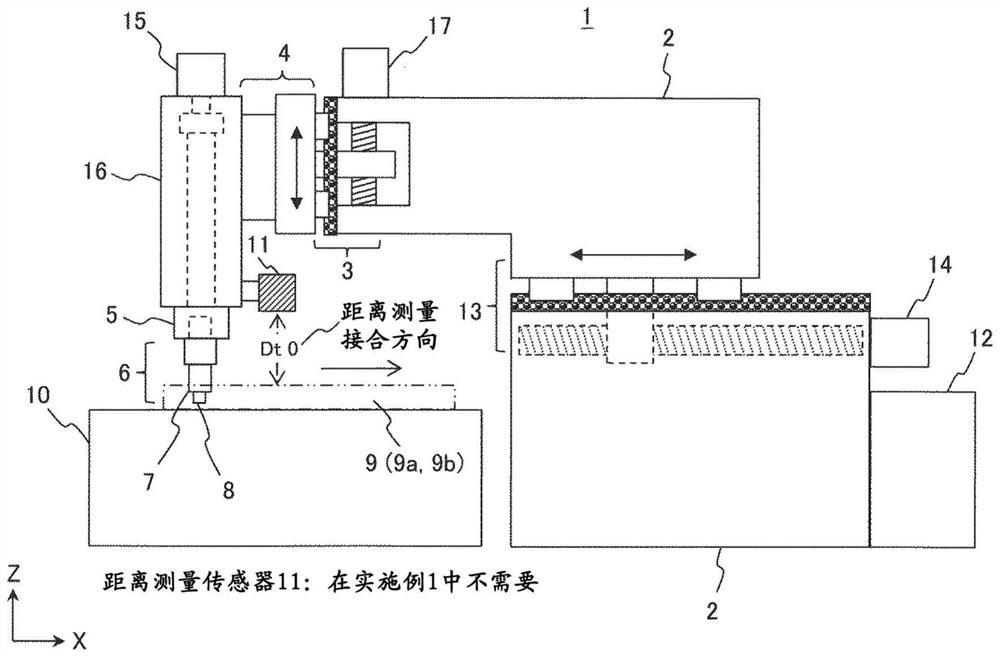

Embodiment 1

[0029] "Basic Controls of This Embodiment"

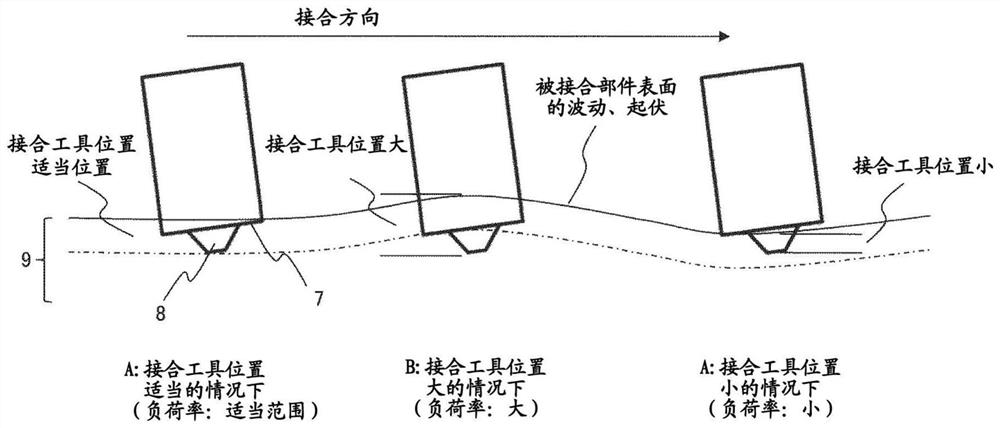

[0030] The friction stir welding device and the friction stir welding method of this embodiment control the Z-axis to move the driving mechanism up and down so that the current state quantity (current state quantity) during friction stir welding is smaller than the reference state quantity indicating the normal range of the state quantity , use the calculated absolute value of the correction to correct the position of the bonding tool in the vertical direction (downward direction of the Z axis), and when the current state quantity is greater than the reference state quantity, use the calculated absolute value of the correction The joint tool position is corrected in the vertical direction (Z-axis upward direction).

[0031] In this embodiment, friction stir welding in which the position of the joining tool is adjusted (corrected) using the load torque (load factor) of the spindle motor as the "state quantity" will be described.

[...

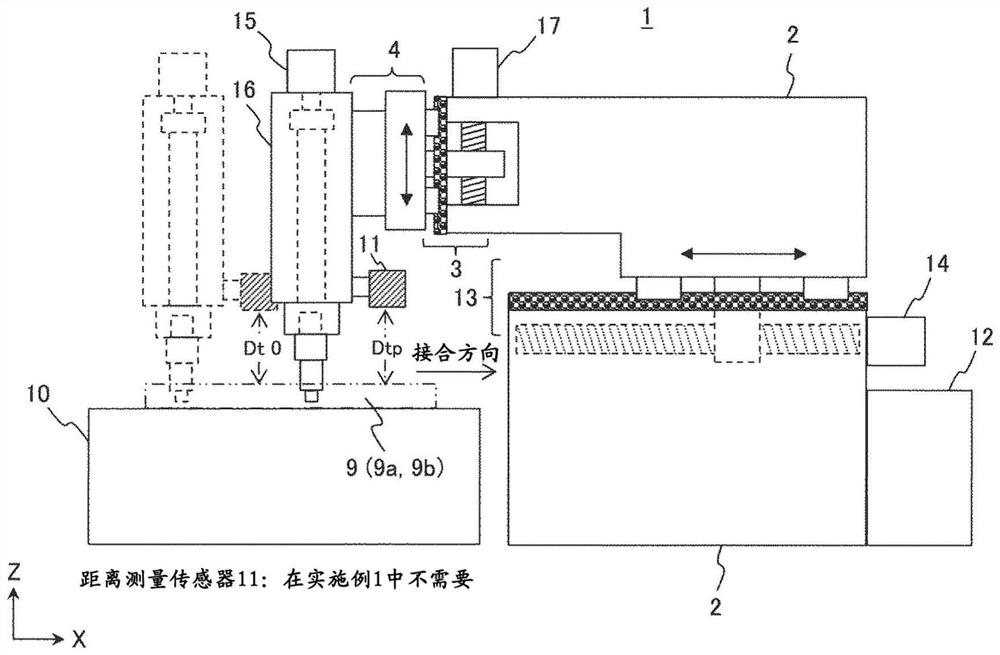

Embodiment 2

[0090] "Basic Controls of This Embodiment"

[0091] In the friction stir welding device and friction stir welding method of this embodiment, the Z-axis is controlled to move the drive mechanism up and down so that when the current state quantity in friction stir welding is smaller than the reference state quantity, the absolute value of the calculated correction amount is used. Correct the position of the bonding head in the upward direction of the Z axis (vertical upward direction), and correct the bonding head in the downward direction of the Z axis (vertical downward direction) by the absolute value of the calculated correction amount when the current state quantity is greater than the reference state quantity Location.

[0092] In this embodiment, friction stir welding in which the position of the bonding tool is controlled (corrected) using the distance from the surface of the member to be bonded to the predetermined position of the bonding head as the "state quantity" wi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com