Aero-engine design point parameter design method

A technology for aero-engine and parameter design, applied in design optimization/simulation, electrical digital data processing, special data processing applications, etc. The effect of rational design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

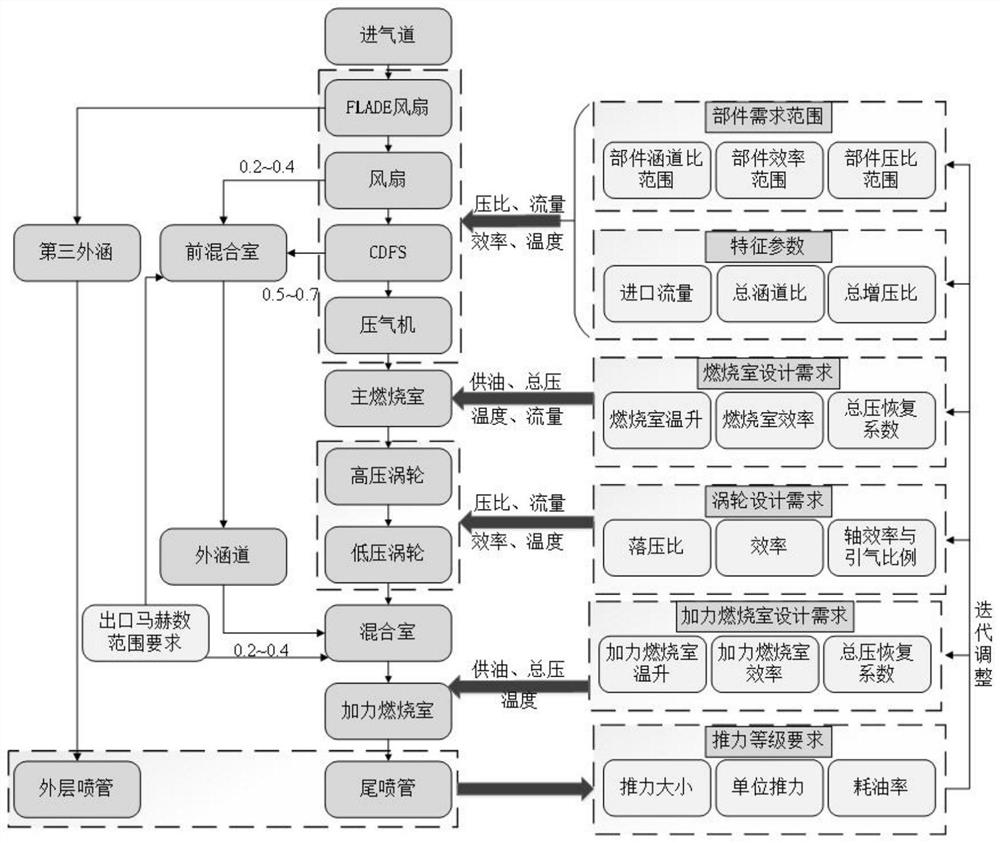

[0114] see Figure 1-Figure 7 , this embodiment provides a method for designing design point parameters of an aero-engine, and the method is mainly used for obtaining design point parameters of an adaptive cycle engine.

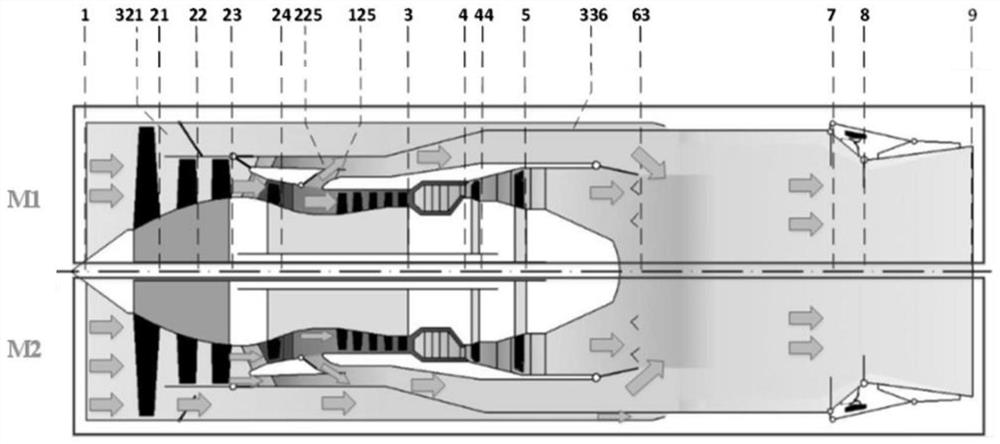

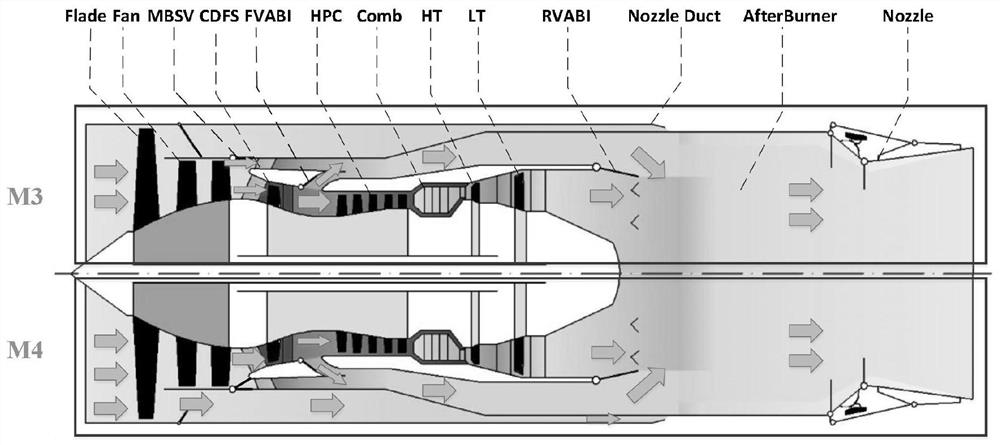

[0115] In the prior art, adaptive cycle engines have many configurations. In this embodiment, an adaptive cycle engine structure is determined based on the flow path characteristics of a typical adaptive cycle engine, wherein the adaptive cycle engine structure and The flow path of the engine configuration is as follows: figure 2 and image 3 As shown, specifically, in the embodiment, the structure of the self-adaptive cycle engine, starting from the inlet 1 of the air inlet, includes the following sections in sequence:

[0116] The first-stage Flade fan blade root outlet 21, the third outer culvert inlet 321, the second-stage fan outlet 22, the core-driven fan-stage inlet 23, the core-driven fan-stage outlet 24, the MBSV duct outlet 225, the CDFS duct out...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap