Noise reduction device for oxygen production equipment

An oxygen production equipment, noise reduction technology, applied in oxygen preparation, sound equipment, instruments, etc., can solve the problem of poor noise reduction effect, etc., and achieve the effect of improving noise reduction effect, reducing transmission intensity, and reducing transmission intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The embodiment of the application discloses a noise reduction device for oxygen production equipment.

[0038] The following is attached Figure 1-5 The application is described in further detail.

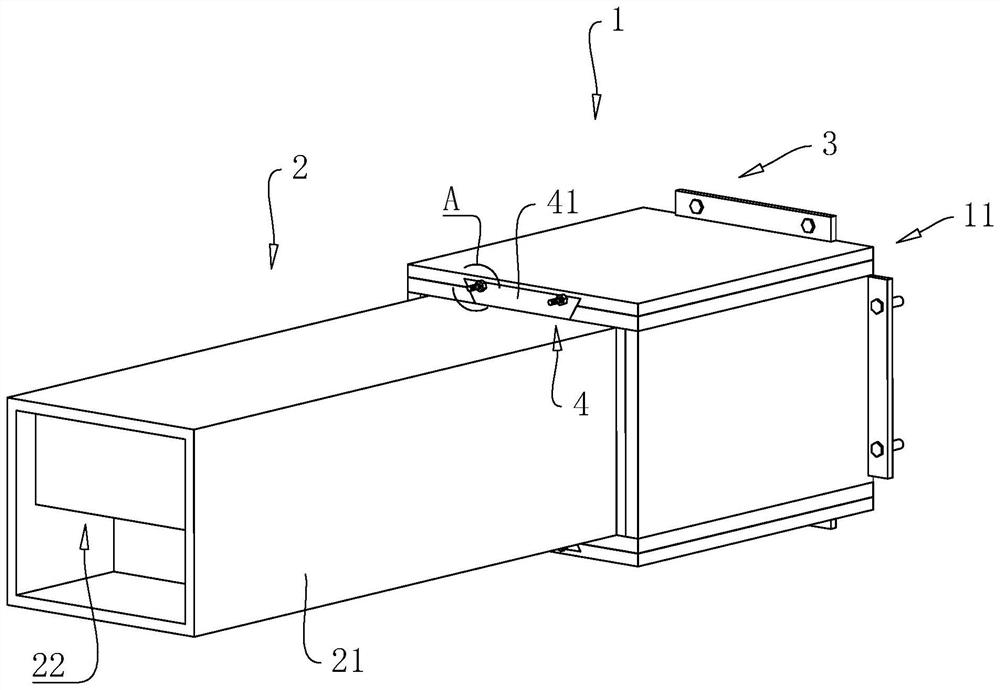

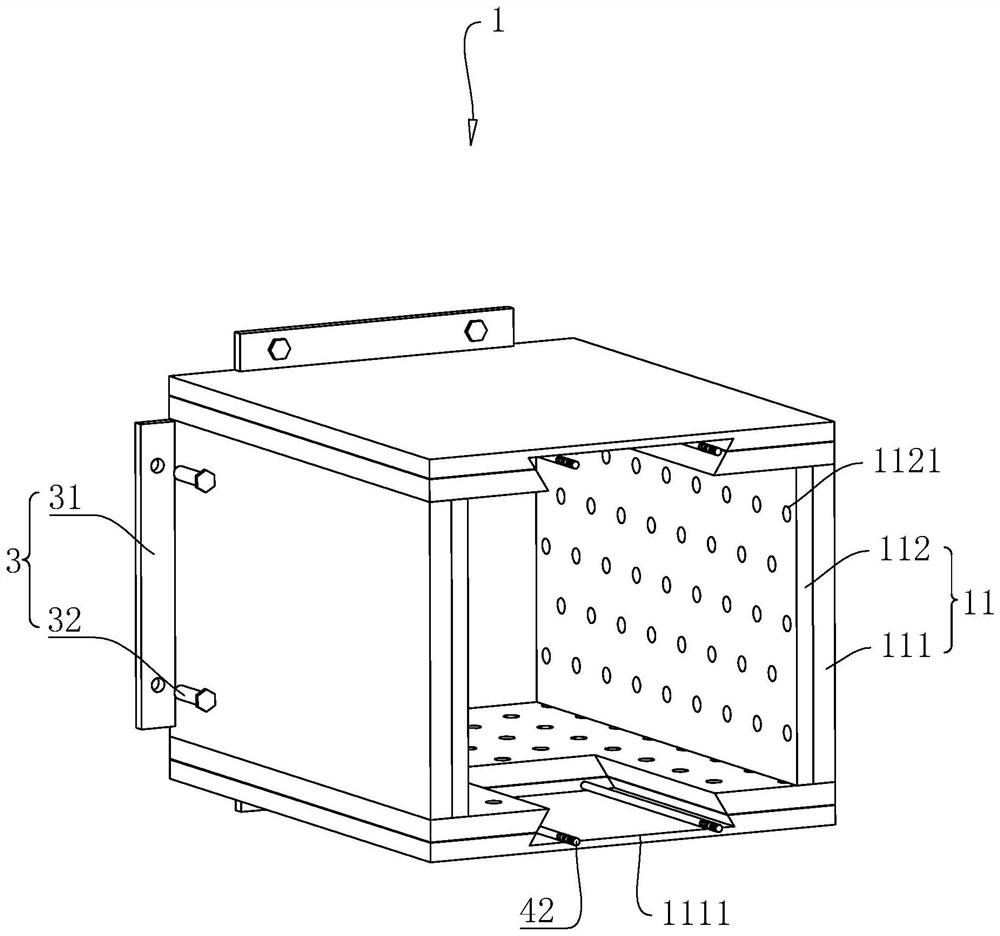

[0039] refer to figure 1 , The noise reduction device includes a sound insulation mechanism 1 and a noise reduction mechanism 2. The sound insulation mechanism 1 is arranged around the periphery of the noise source, so as to reduce the noise of the noise source and reduce the propagation range of the noise. The noise reduction mechanism 2 is arranged on the sound insulation mechanism 1 to eliminate and reduce the noise passing through the sound insulation mechanism 1, and further improve the noise reduction effect of the noise reduction device.

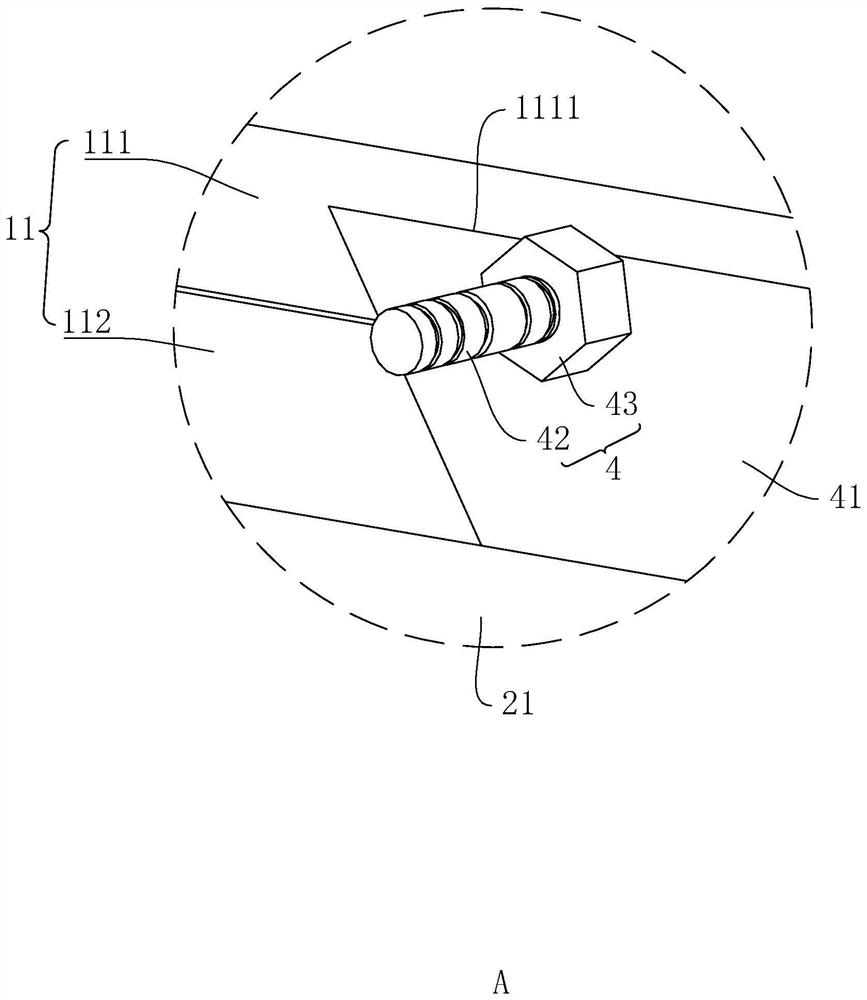

[0040] refer to figure 2 with image 3 , The sound insulation mechanism 1 includes multiple sets of sound-absorbing pieces 11, and in this embodiment, the number of sound-absorbing pieces 11 may be four sets. Each set of soun...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap