Front sun shield of automobile

A technology for sun visors and automobiles, which is applied in the field of auto parts. It can solve the problems of poor strength of the front sun visor, affect driving vision, and short service life, etc., and achieve the effect of firm structure, reduced transmission intensity, and not easy to age

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

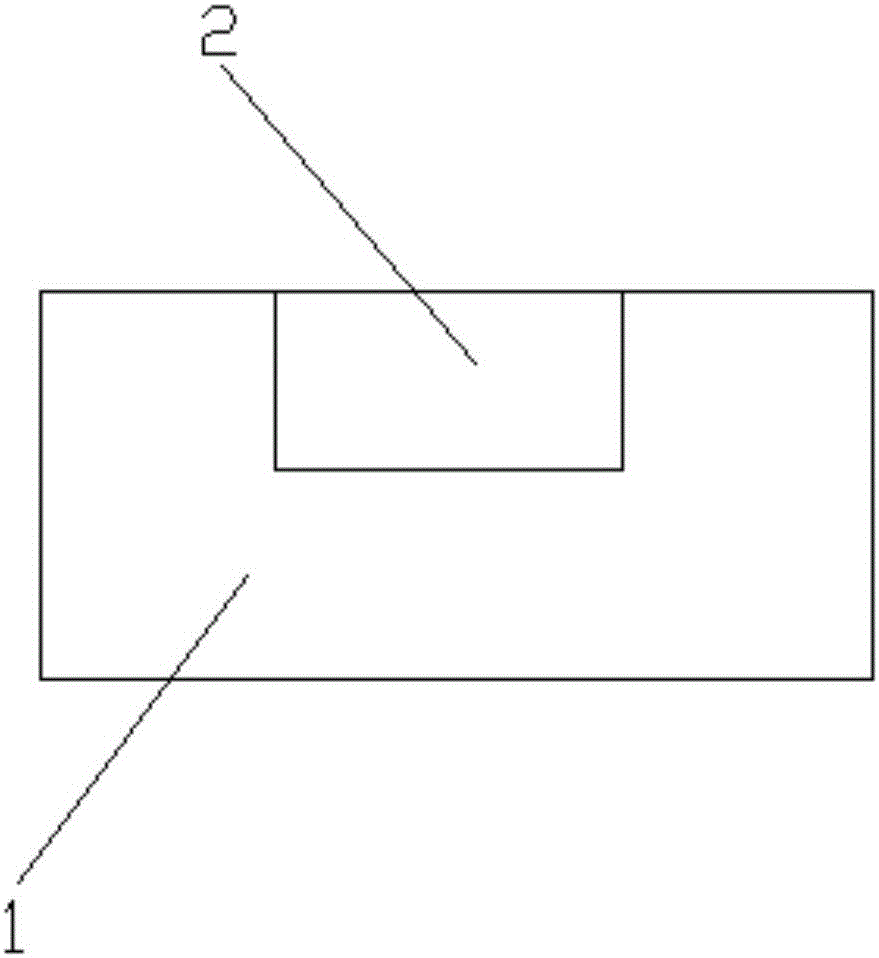

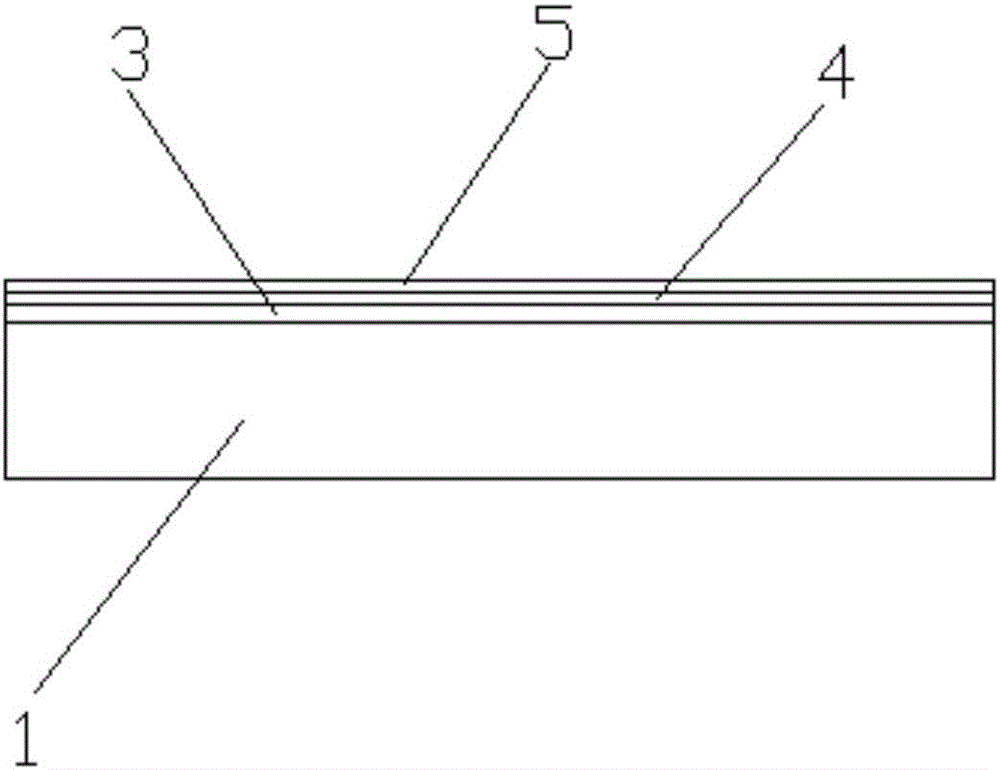

[0014] combine figure 1 , figure 2 , The invention discloses a car front sun visor, comprising a sun visor substrate 1 and a flat mirror 2; the sun visor substrate 1 is made of an acrylic plate; the thickness of the sun visor substrate 1 is preferably 0.3-3.5cm. The plane mirror 2 is mounted on the sun-shading substrate 1 and located on the backlight surface of the sun-shading substrate 1 ; the plane mirror 2 is preferably located on the upper side of the sun-shading substrate 1 . The light-facing surface of the sunshade substrate 1 is sequentially coated with a heat-insulating coating 3 and a reflective coating; a sun-proof polyester film 5 is pasted on the outside of the reflective coating; the heat-insulating coating 3 is indium oxide Tin coating; the reflective coating is metallic silver reflective coating.

[0015] In order to further improve sunshade and sunscreen performance while taking light transmittance into consideration, the thickness of the heat-shielding coat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com