Linear transport system with minimum transport pitch

A technology of transportation system and transportation path, which is applied in the direction of propulsion system, transportation and packaging, conveyor, etc., and can solve the problems of difficult manufacturing of transportation components, weak propulsion, small interaction surface, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

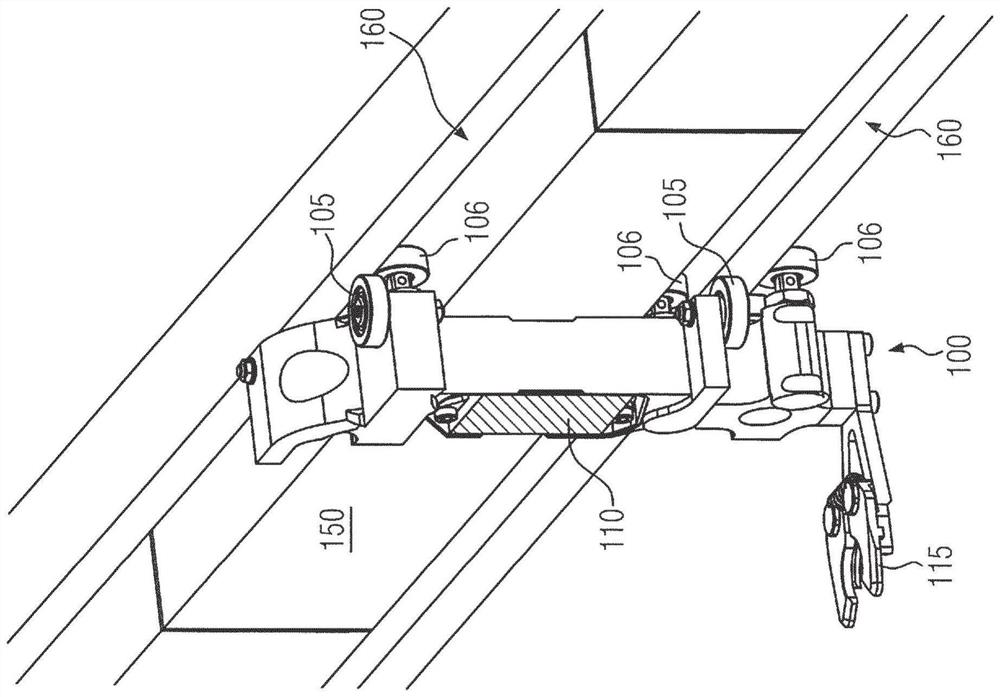

[0051] Exemplary embodiments of transport elements guided on one side as known from the prior art are in figure 1 shown in . The transport element 100 shown here has a secondary part 110 which, as known per se, carries a sequence of magnets on the side facing the long stator 150 , which interact with the electrical winding of the long stator. Since the long stator 150 is only arranged on one side of the transport element 100, the transport element is kept at Arranged on the guide rail 160 on one side. The transport element 100 shown as an example is movably supported on the side of a guide rail 160 of a long-stator linear motor via running rollers 106 and guide rollers 105 .

[0052] However, the transport element can also have running rollers and guide rollers on the side opposite the guide rail 160 in order to be guided on the opposite guide rail in the branching region of the switch. Correspondingly, the secondary part can also have magnets or poles of magnets on both si...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com