Dry ice generating and cleaning device

A cleaning device, dry ice technology, applied in cleaning methods and utensils, cleaning methods using liquids, carbon compounds, etc., can solve the problems of low use efficiency of dry ice pellets, melting of dry ice pellets, etc., to prevent secondary cleaning of objects to be cleaned, Easy to store, uniform size effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

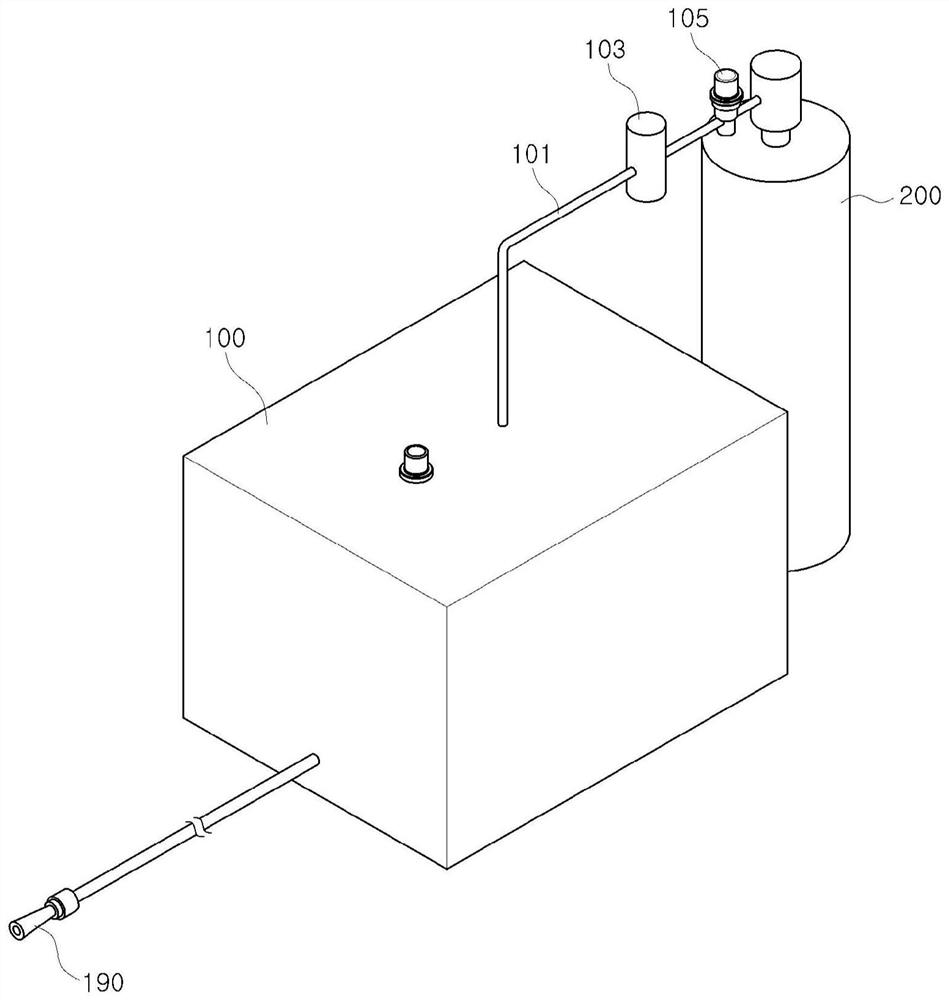

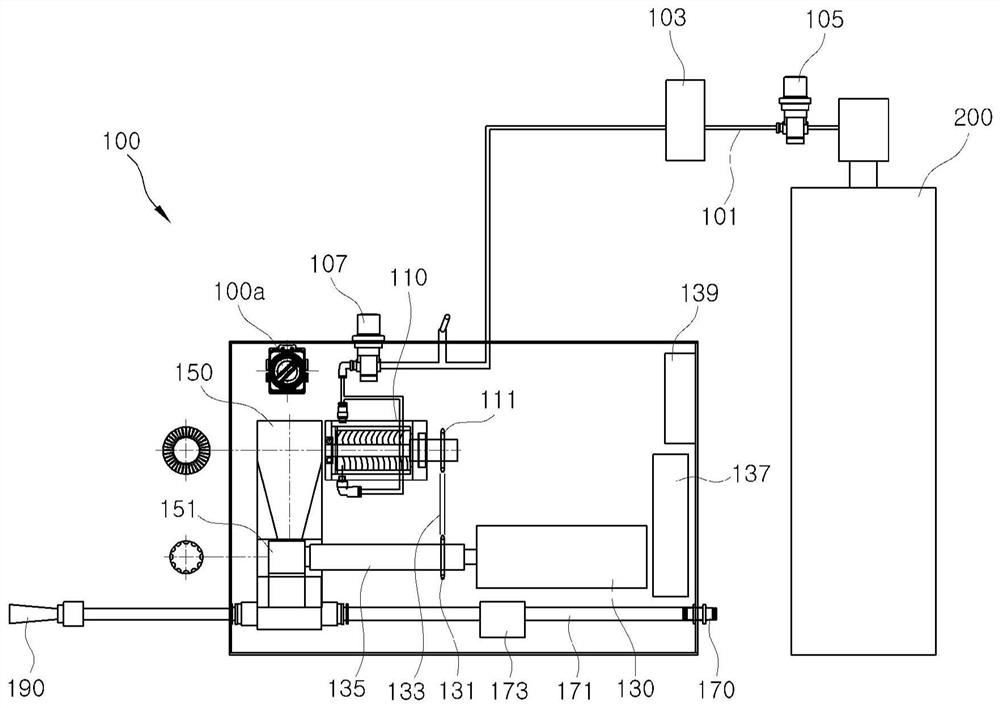

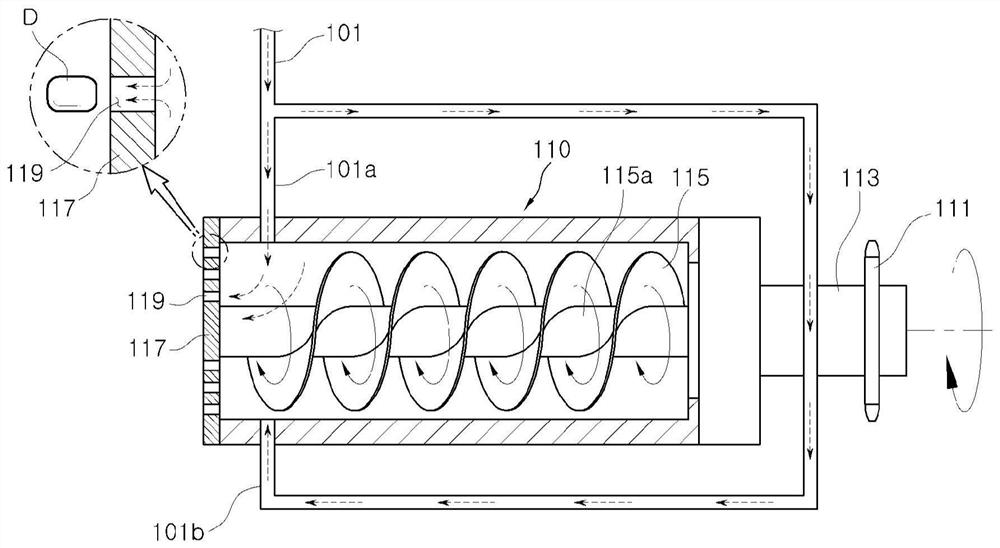

[0043] Such as figure 1 , figure 2 As shown, the dry ice generation and cleaning device according to an embodiment of the present invention includes a supply tank 200 containing liquefied carbon dioxide and a chamber 100 for generating dry ice and cleaning it.

[0044] The chamber 100 is equipped with a housing space in which a structure for generating and ejecting dry ice can be installed, and can be equipped with a switch 100a for controlling the generation and ejection of dry ice on the outside.

[0045] Also, the chamber 100 may be protrudingly provided with a nozzle 190 on the outside so that dry ice can be ejected.

[0046] The supply tank 200 is provided with a connection pipe 101 between the chamber 100 and the supply tank 200 in order to supply liquefied carbon dioxide to the chamber 100 , and a first regulator 103 , a second regulator 107 and a connection valve 105 may be provided in the connection pipe.

[0047] The first regulator 103 is provided near the supply...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com