Coupling

A coupling and bearing technology, applied in couplings, elastic couplings, mechanical equipment, etc., can solve the problems of low efficiency, stress, system imbalance, etc., and achieve the effect of reducing friction and wear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

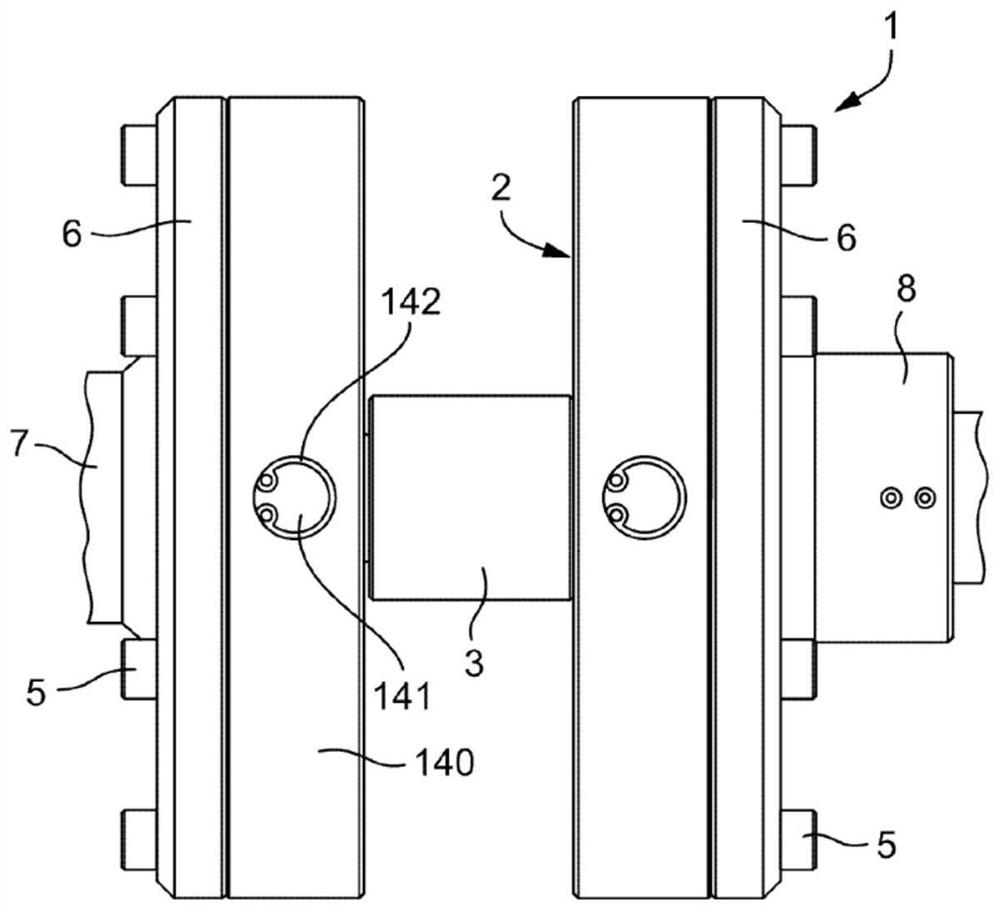

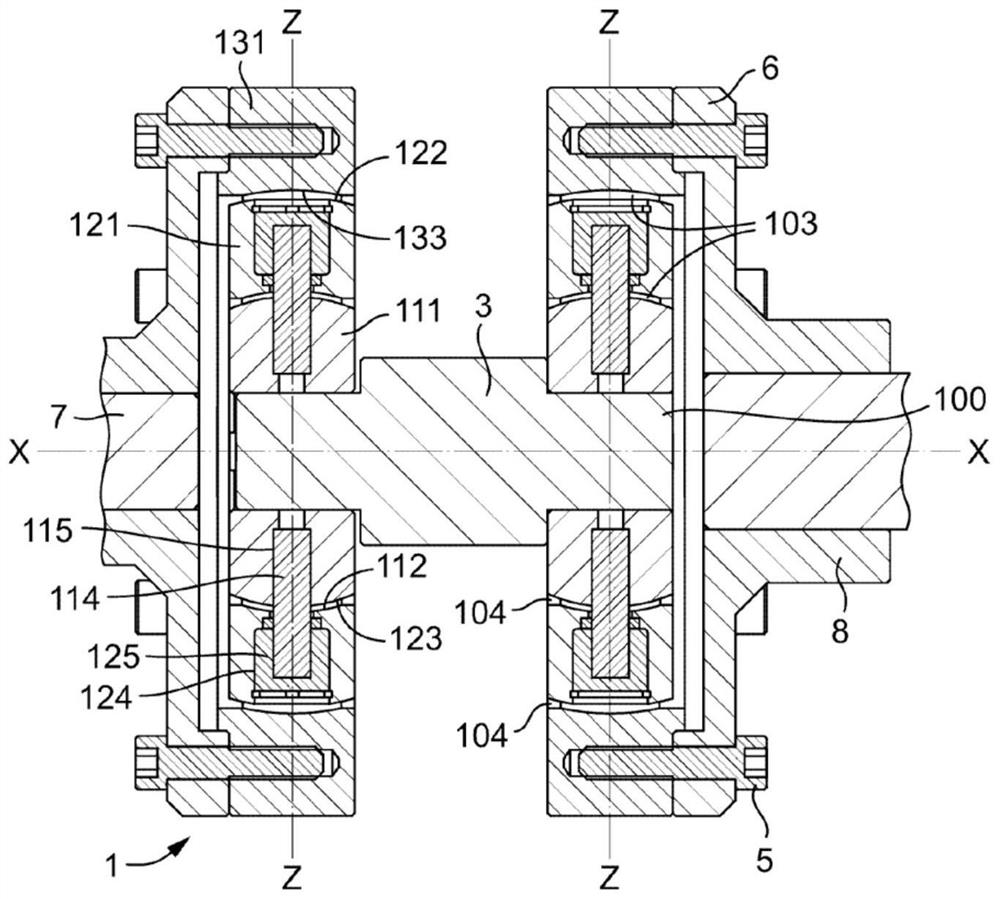

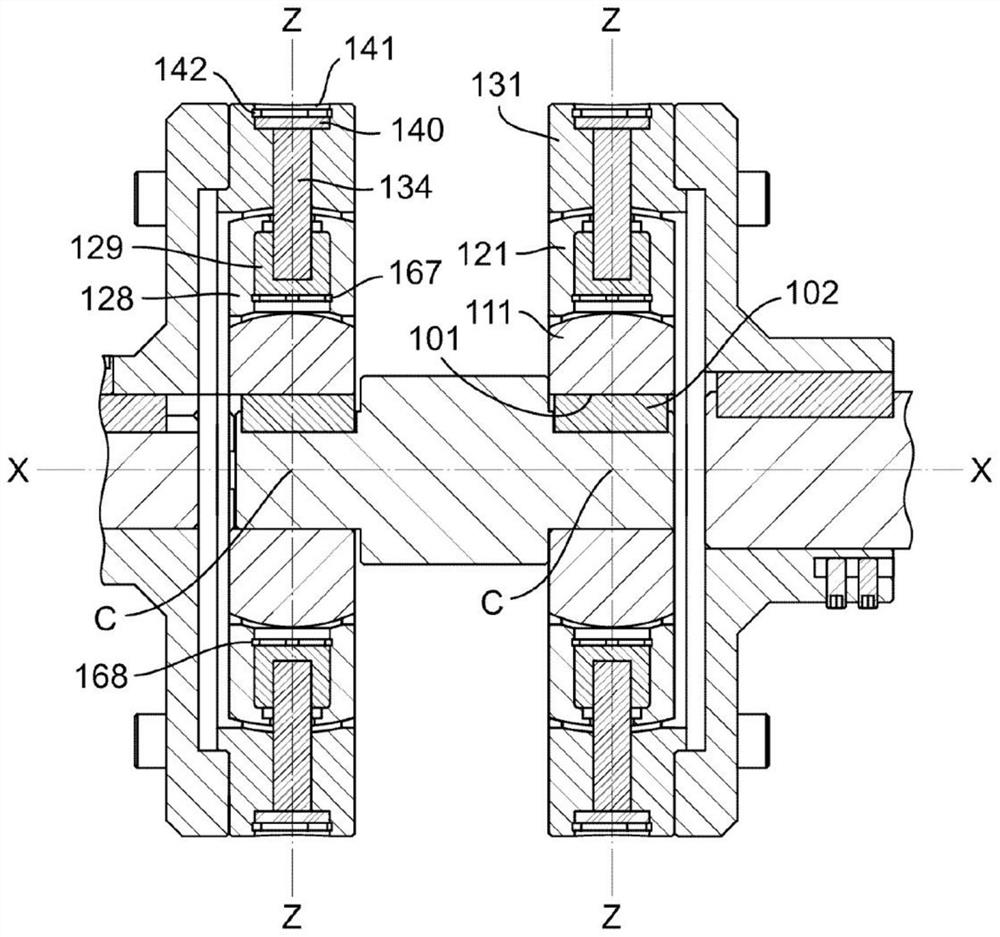

[0032] Figure 1 to Figure 4 Two example couplings 1 and 2 of the invention are shown joined by a shaft 3 used as a replacement for a Carden shaft.

[0033] Each of the couplings 1 and 2 includes an inner ring member 111 , a middle ring member 121 and an outer ring member 131 . The center of the inner member 111 is located on the central axis X. As shown in FIG. The inner member 111 has an outer convex spherical surface 112 , which is a convex spherical surface centered at point C on the central axis X .

[0034] The inner annular member 111 has a central aperture 100 to receive the shaft 3 . The central aperture 100 has a keyway 101 which is engaged by a corresponding key 102 on the shaft 3 . Alternatively, the ends of the shaft member 3 may have splines to engage corresponding splines around the central aperture.

[0035] The intermediate annular member 121 has an inner concave spherical surface 123 which is a spherical segment complementary to the outer convex spherical...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com