Double faced adhesive tape pressure maintaining work station for adhesive tape pasting and film tearing production

A technology of double-sided tape and sticking, which is applied in the field of double-sided tape pressure-maintaining stations for the production of adhesive and tearing films, can solve the problems of poor use performance of pressure-holding stations, inability to apply adhesive and pressure-holding control, and troublesome operation. To achieve the effect of adding glue, simple structure and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

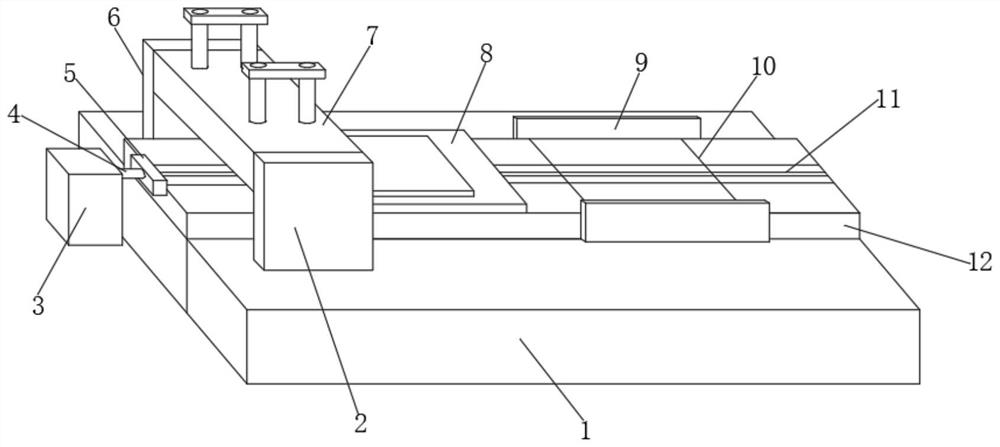

[0028] Such as Figure 1-6 As shown, a double-sided adhesive pressure maintaining station for adhesive tearing film production includes an adhesive seat 1, the upper end of the adhesive seat 1 is positioned and installed with a carrier assembly line 12, and the upper end of the carrier assembly line 12 is provided with an adhesive tape The vehicle 8 is equipped with a slide rail 11 on the inside of the vehicle assembly line 12, the vehicle buffer seat 10 is installed at the tail end of the vehicle assembly line 12, and the two ends of the vehicle buffer seat 10 are equipped with a baffle plate 9 and a glue seat 1 No. 2 support frame 2 and No. 1 support frame 6 are respectively installed at the positions on both sides of the carrier assembly line 12 at the front end.

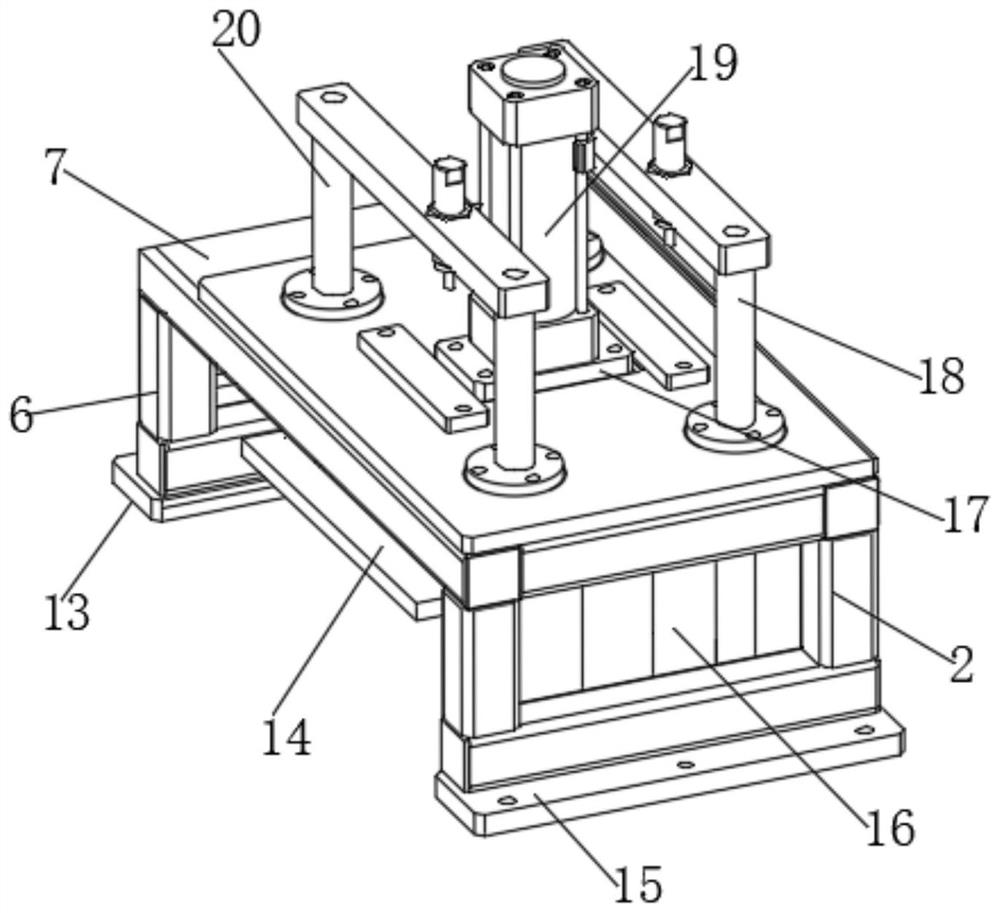

[0029] Further, a No. 2 positioning seat 15 is installed between the No. 2 support frame 2 and the glue base 1, and a No. 1 positioning seat 13 is installed between the No. 1 support frame 6 and the No. 1 positio...

Embodiment 2

[0033] On the basis of Example 1, as Figure 1-6 As shown, a double-sided adhesive pressure maintaining station for adhesive tearing film production includes an adhesive seat 1, the upper end of the adhesive seat 1 is positioned and installed with a carrier assembly line 12, and the upper end of the carrier assembly line 12 is provided with an adhesive tape The vehicle 8 is equipped with a slide rail 11 on the inside of the vehicle assembly line 12, the vehicle buffer seat 10 is installed at the tail end of the vehicle assembly line 12, and the two ends of the vehicle buffer seat 10 are equipped with a baffle plate 9 and a glue seat 1 No. 2 support frame 2 and No. 1 support frame 6 are respectively installed at the positions on both sides of the carrier assembly line 12 at the front end.

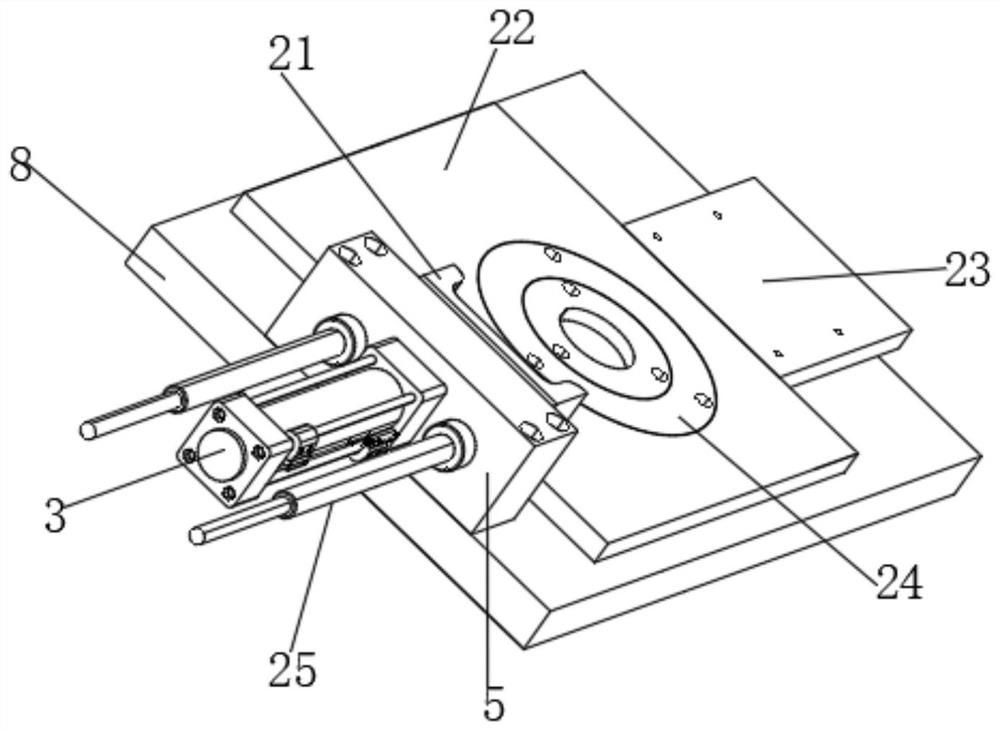

[0034] Further, a vehicle control cylinder 3 is installed at the front end of the glue base 1, and one end of the vehicle control cylinder 3 is connected to a drive rod 4, a slider 5, and th...

Embodiment 3

[0037] On the basis of embodiment one and embodiment two, such as Figure 1-6 As shown, a double-sided adhesive pressure maintaining station for adhesive tearing film production includes an adhesive seat 1, the upper end of the adhesive seat 1 is positioned and installed with a carrier assembly line 12, and the upper end of the carrier assembly line 12 is provided with an adhesive tape The vehicle 8 is equipped with a slide rail 11 on the inside of the vehicle assembly line 12, the vehicle buffer seat 10 is installed at the tail end of the vehicle assembly line 12, and the two ends of the vehicle buffer seat 10 are equipped with a baffle plate 9 and a glue seat 1 No. 2 support frame 2 and No. 1 support frame 6 are respectively installed at the positions on both sides of the carrier assembly line 12 at the front end.

[0038] Further, the bottom position of the drive cylinder 19 is connected with a cylinder body 26, the bottom of the cylinder body 26 is connected with a lifting...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com