Patents

Literature

37results about How to "Good pressure retention" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

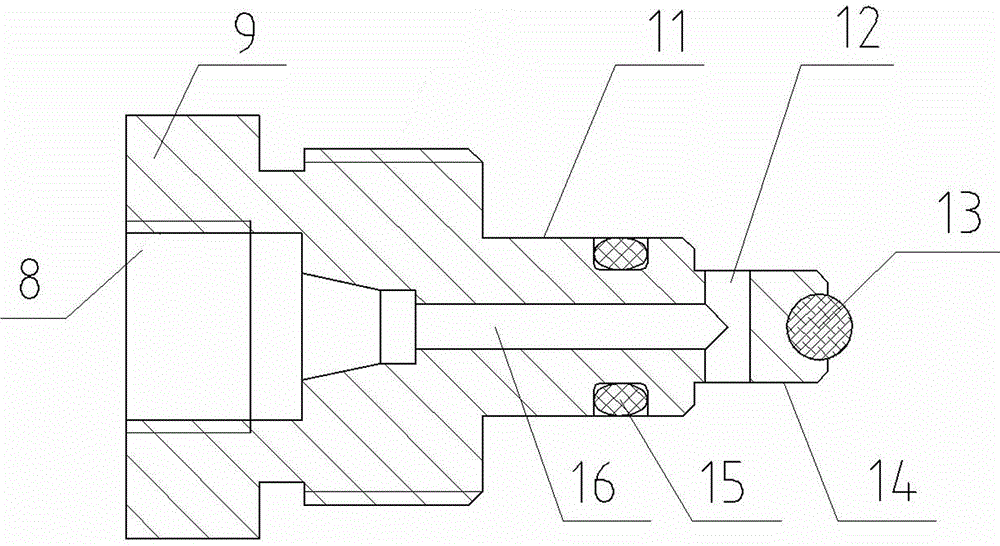

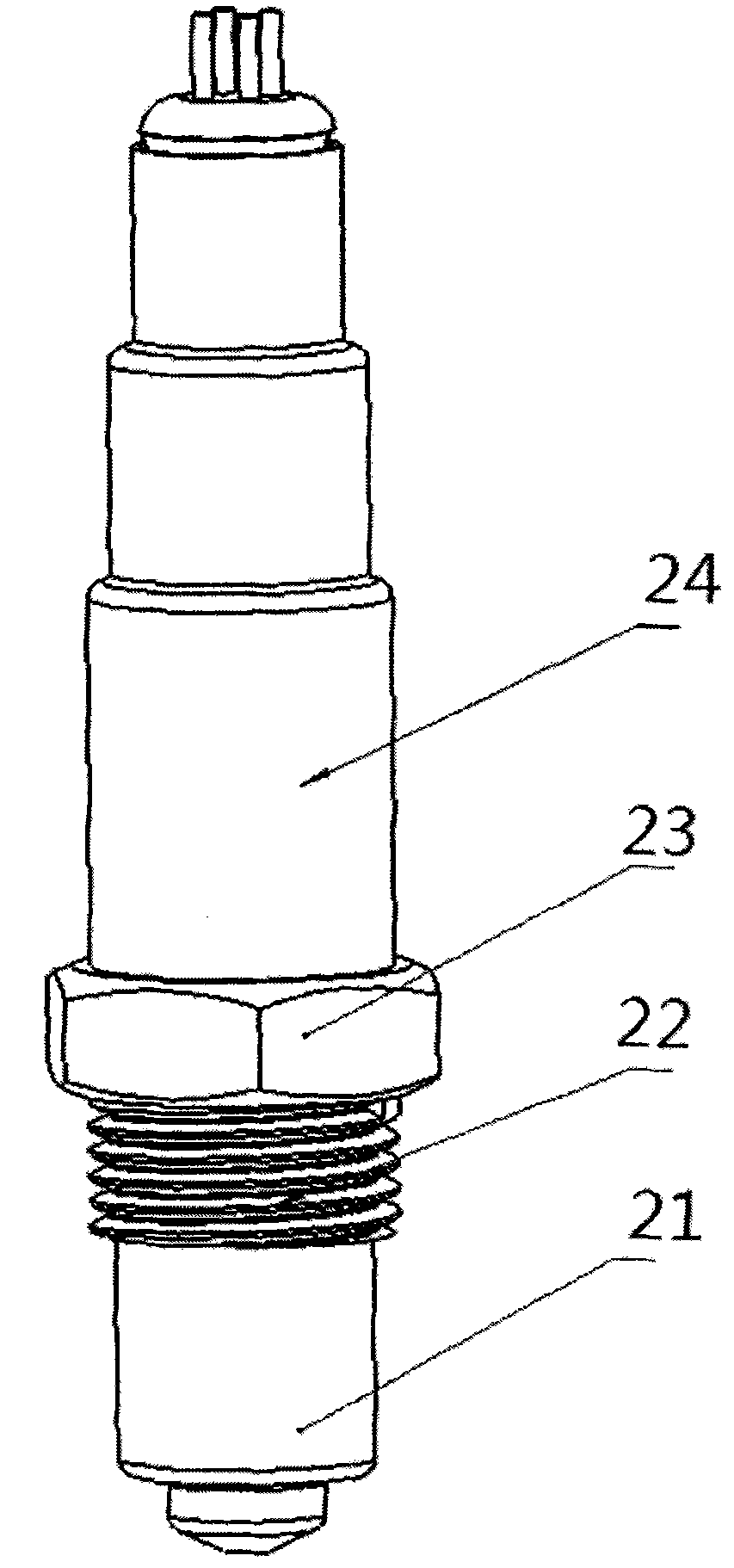

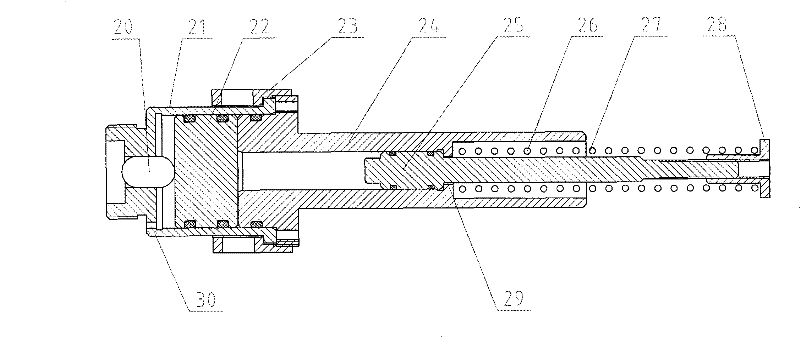

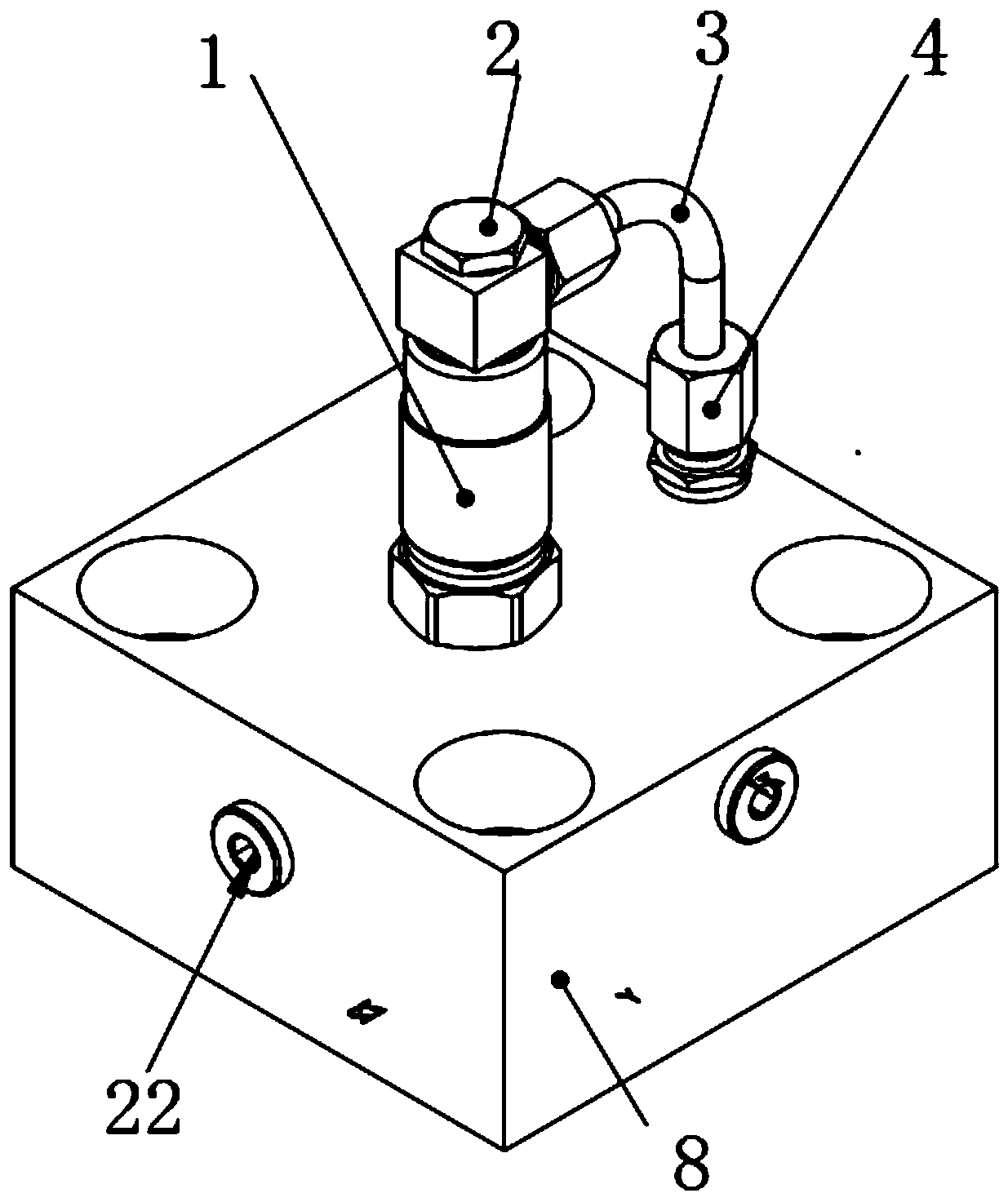

Liquid pressure-maintaining and sampling tube

InactiveCN104792578ASimple structureEasy to operateWithdrawing sample devicesEngineeringSampling valve

The invention discloses a liquid pressure-maintaining and sampling tube which comprises a connector, two cavities and two sampling valves, wherein the two cavities are respectively connected with the two ends of the connector; a communicating hole is formed in the connector and communicated with the two cavities, and ladder-shaped through holes are an outer end hole, a sealing hole, a flow guide groove and a flow guide hole from outside to inside in sequence and are formed in the two cavities; each sampling valve is composed of a valve body, a sealing shaft and a valve rod which are connected in sequence, matched with the corresponding ladder-shaped through hole through threads and fixed in the ladder-shaped through hole, each sealing shaft is in close fit with the corresponding sealing hole, a ball is propped against the end part of each flow guide hole, and pistons are respectively arranged in the two cavities. The liquid pressure-maintaining and sampling tube disclosed by the invention can realize spontaneous sampling without an additional drive device, is simple in structure, convenient to operate, good in pressure-maintaining property and reliable in sampling and can be recycled.

Owner:ZHEJIANG UNIV

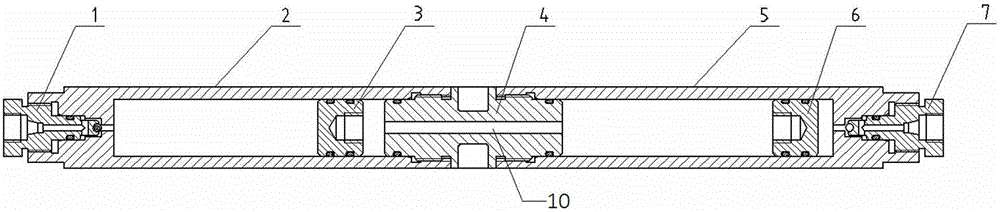

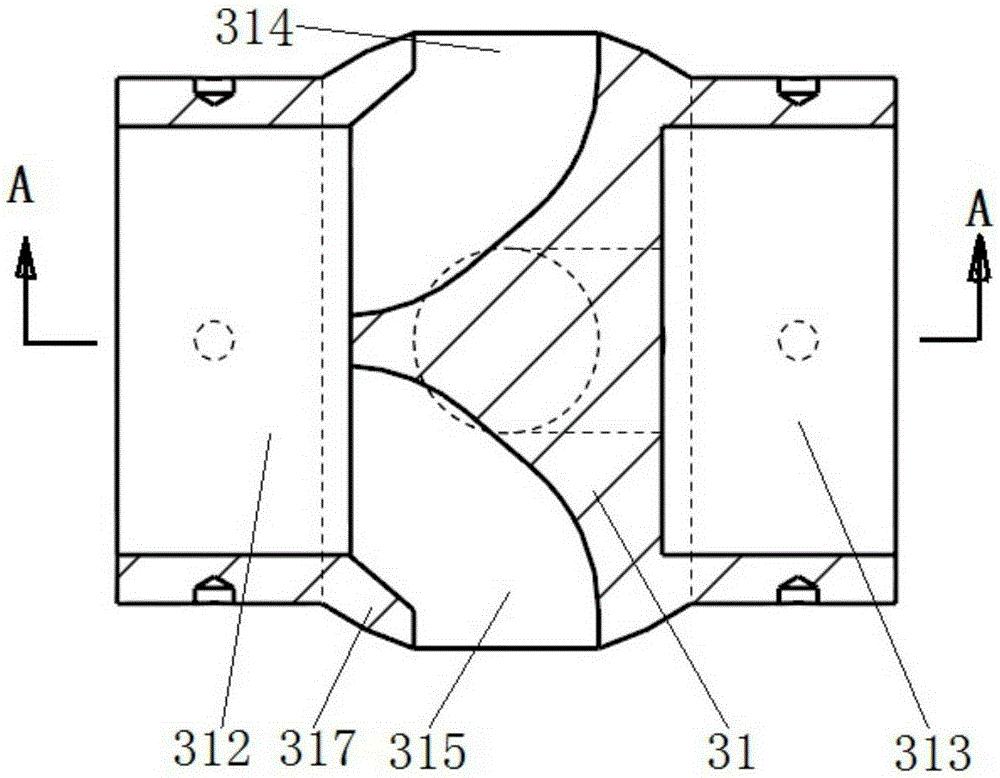

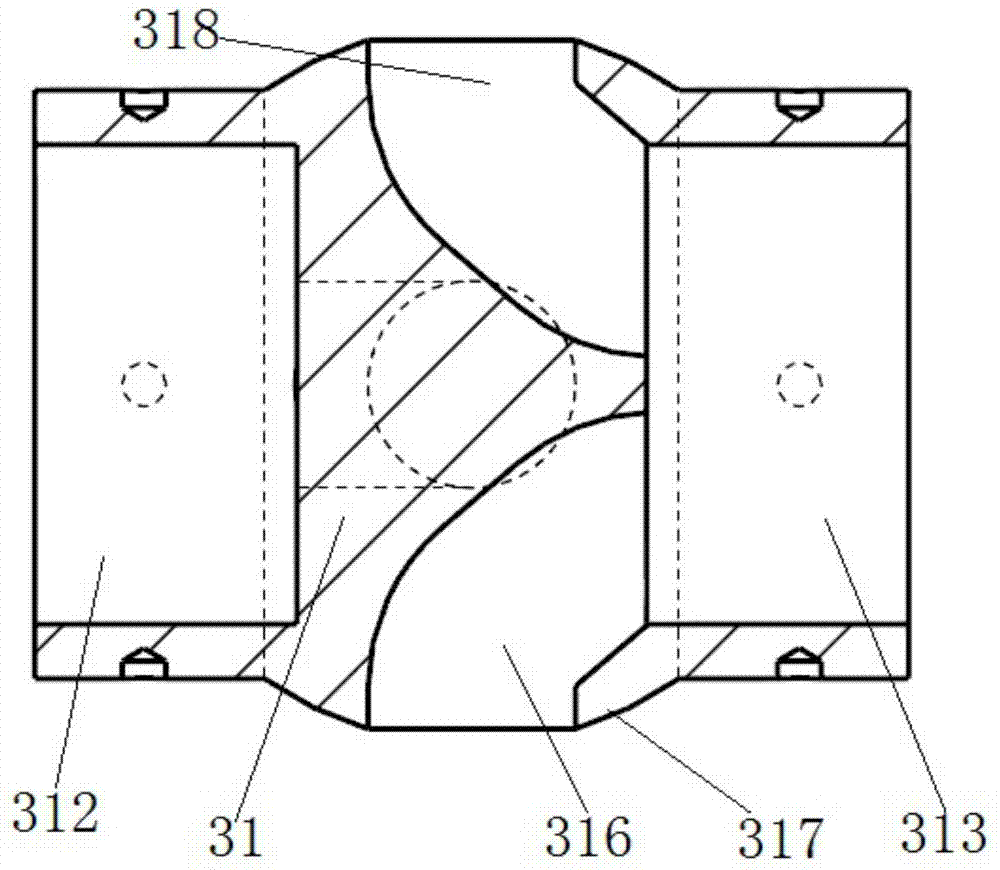

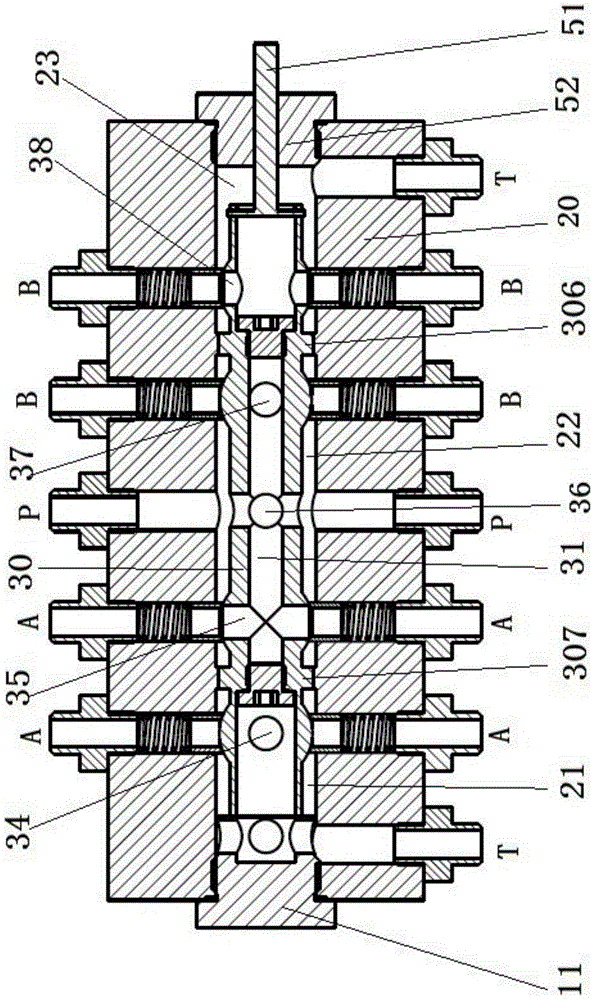

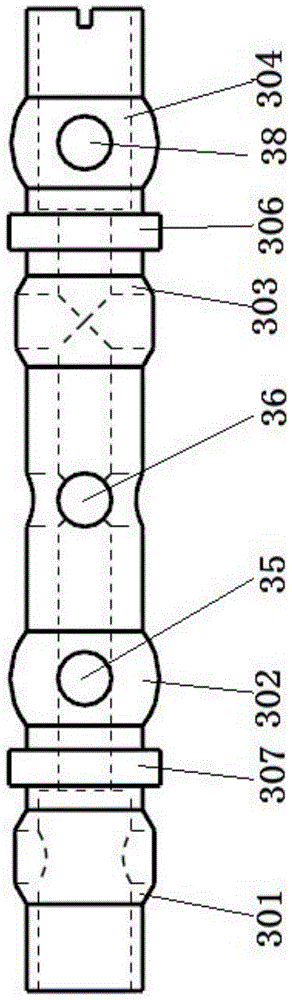

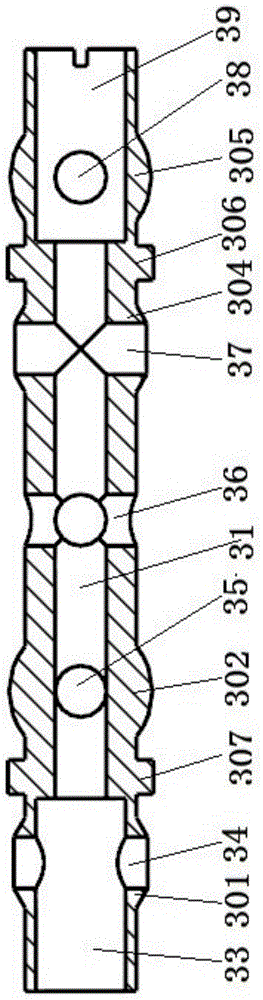

Rotary valve type valve rod and control valve

ActiveCN105298963ASimplify processing difficultyReduce processing difficultyPlug valvesServomotor componentsRotary valveControl valves

The invention relates to a rotary valve type valve rod and a control valve in order to overcome the defects of difficult machining and high fabrication cost of existing rotary valve type valve rods. The rotary valve type valve rod comprises a plurality of valve rod sections; valve rod oil channels are designed in the valve rod sections; the adjacent valve rod sections are sequentially and fixedly connected in the axial direction; the positions, on the axial end faces of the valve rod sections, of the valve rod oil channels are communicated with the outside or with the valve rod oil channels in the adjacent valve rod sections; some valve rod sections are provided with spherical surface joints which are provided with annular spherical surfaces surrounding the valve rod sections; each annular spherical surface is provided with a valve rod oil opening which is communicated with the corresponding valve rod oil channel. The valve rod is mainly composed of the multiple valve rod sections, the machining difficulty of the valve rod sections is low, and molding for forming the valve rod oil channels is simple. Meanwhile, the structures of part of the multiple valve rod sections forming the valve rod can be made to be identical, the interchangeability can be greatly improved, and the machining difficulty can be greatly reduced.

Owner:LIUZHOU LIUGONG HYDRAULIC COMPONENTS +1

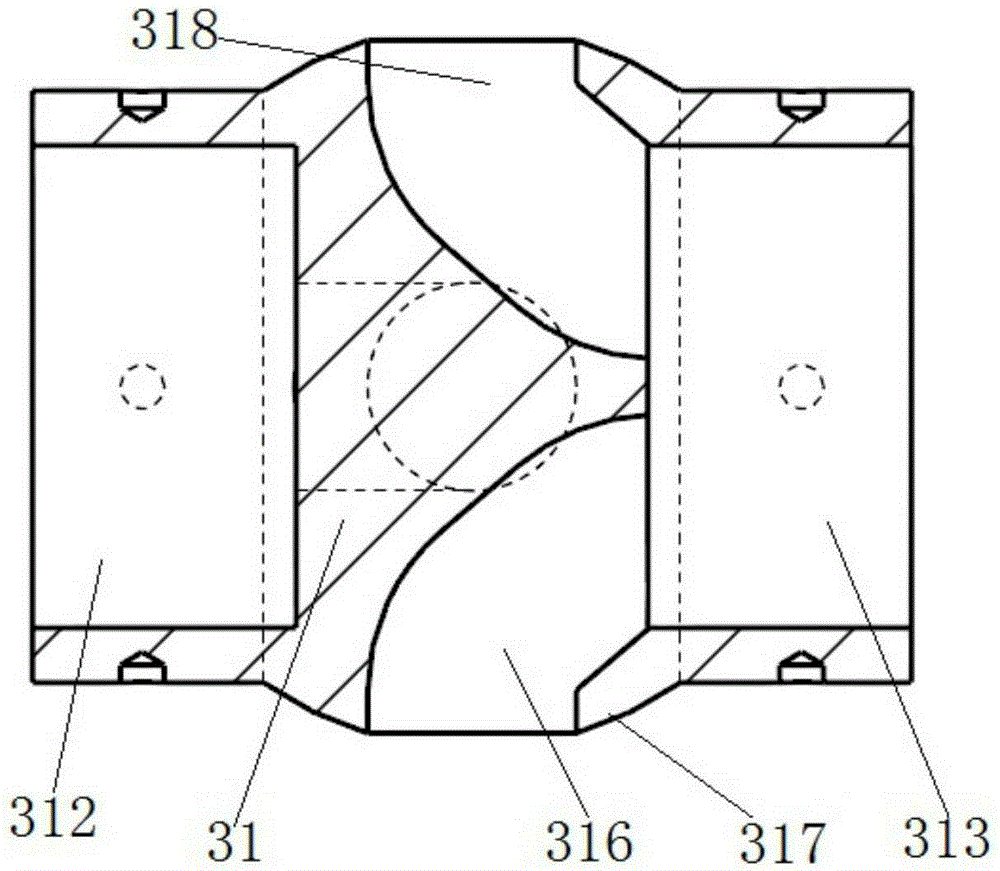

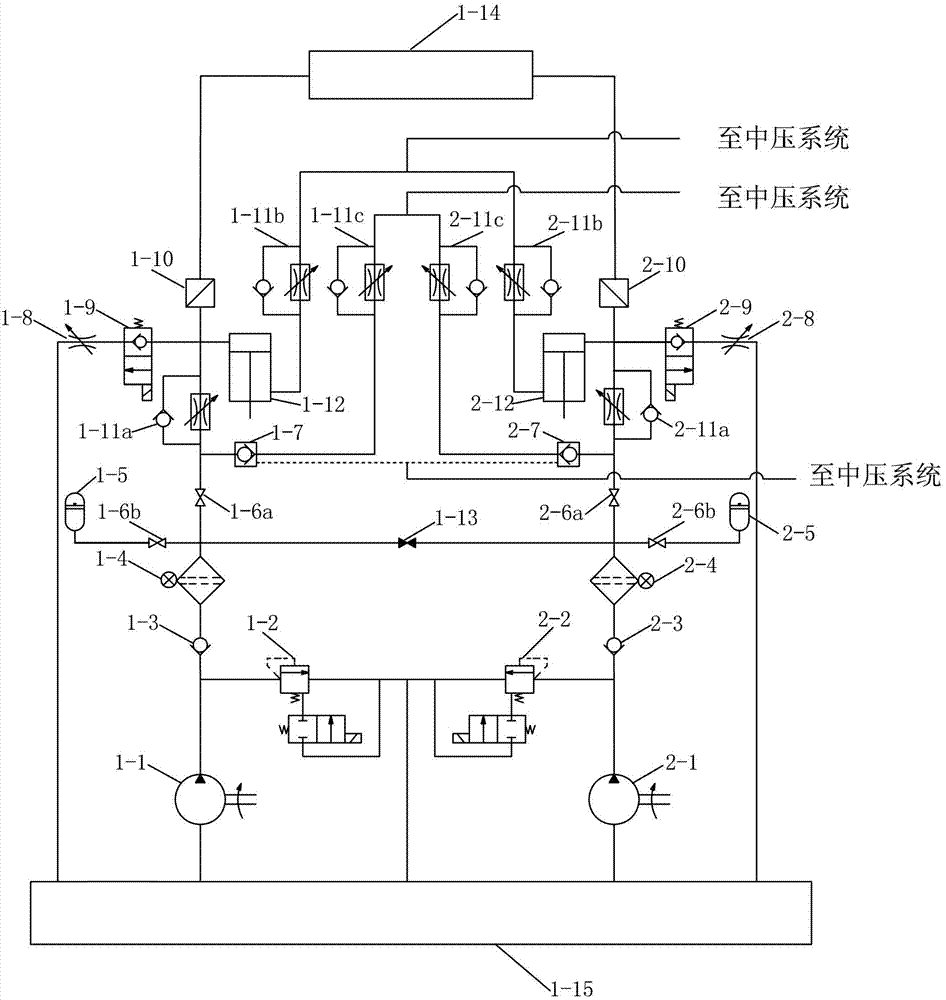

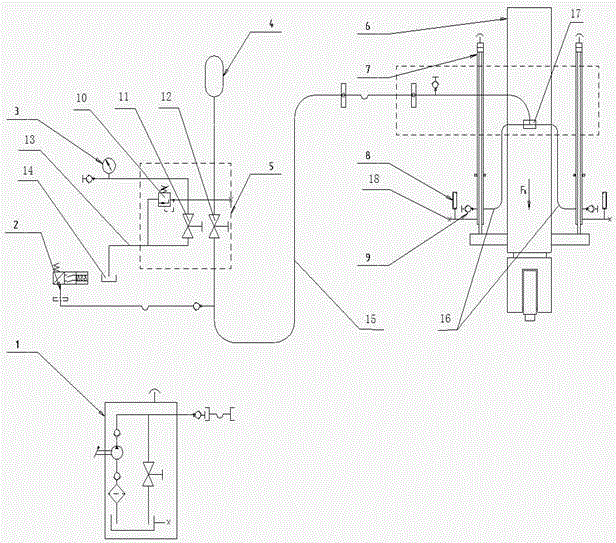

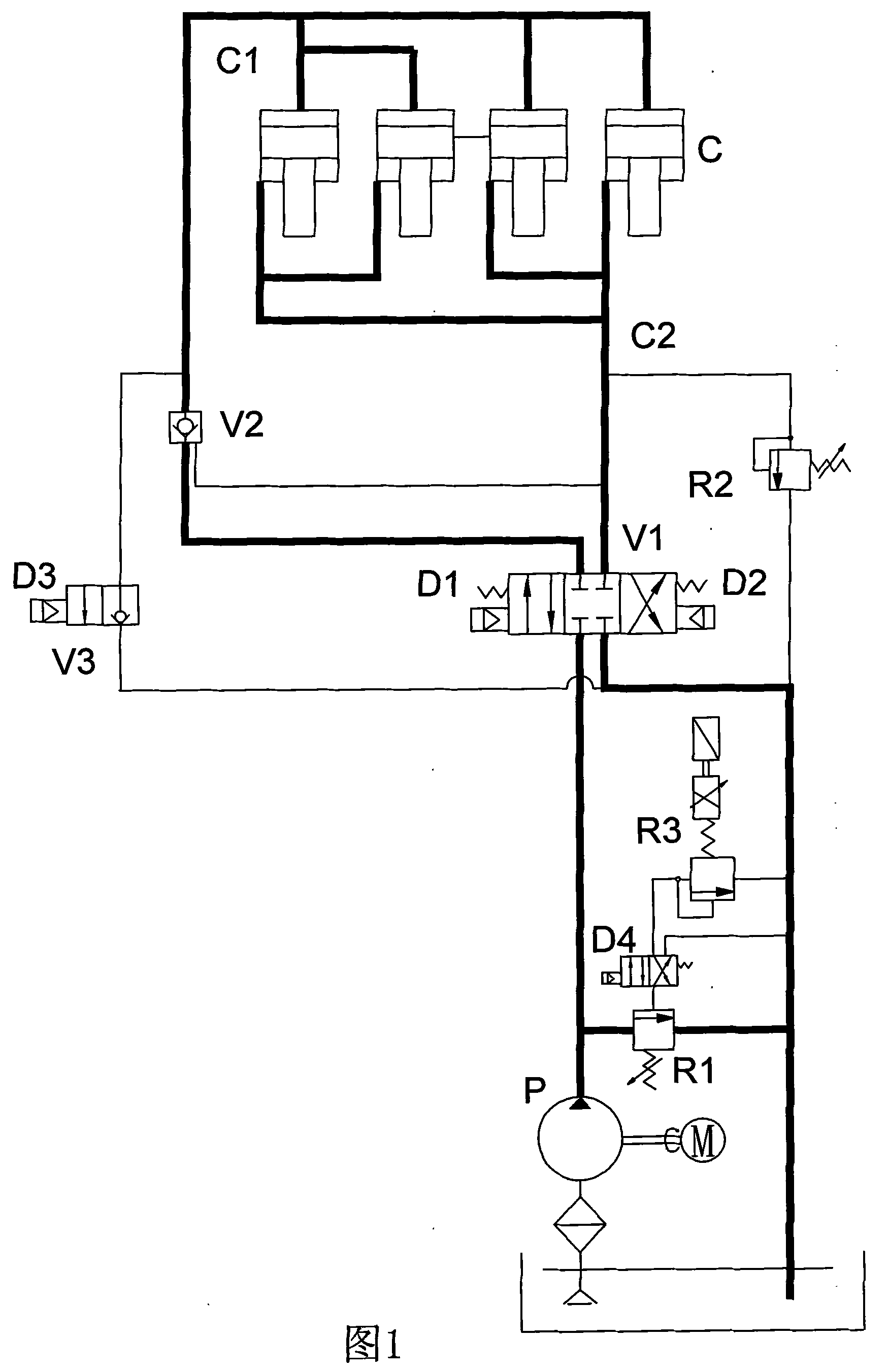

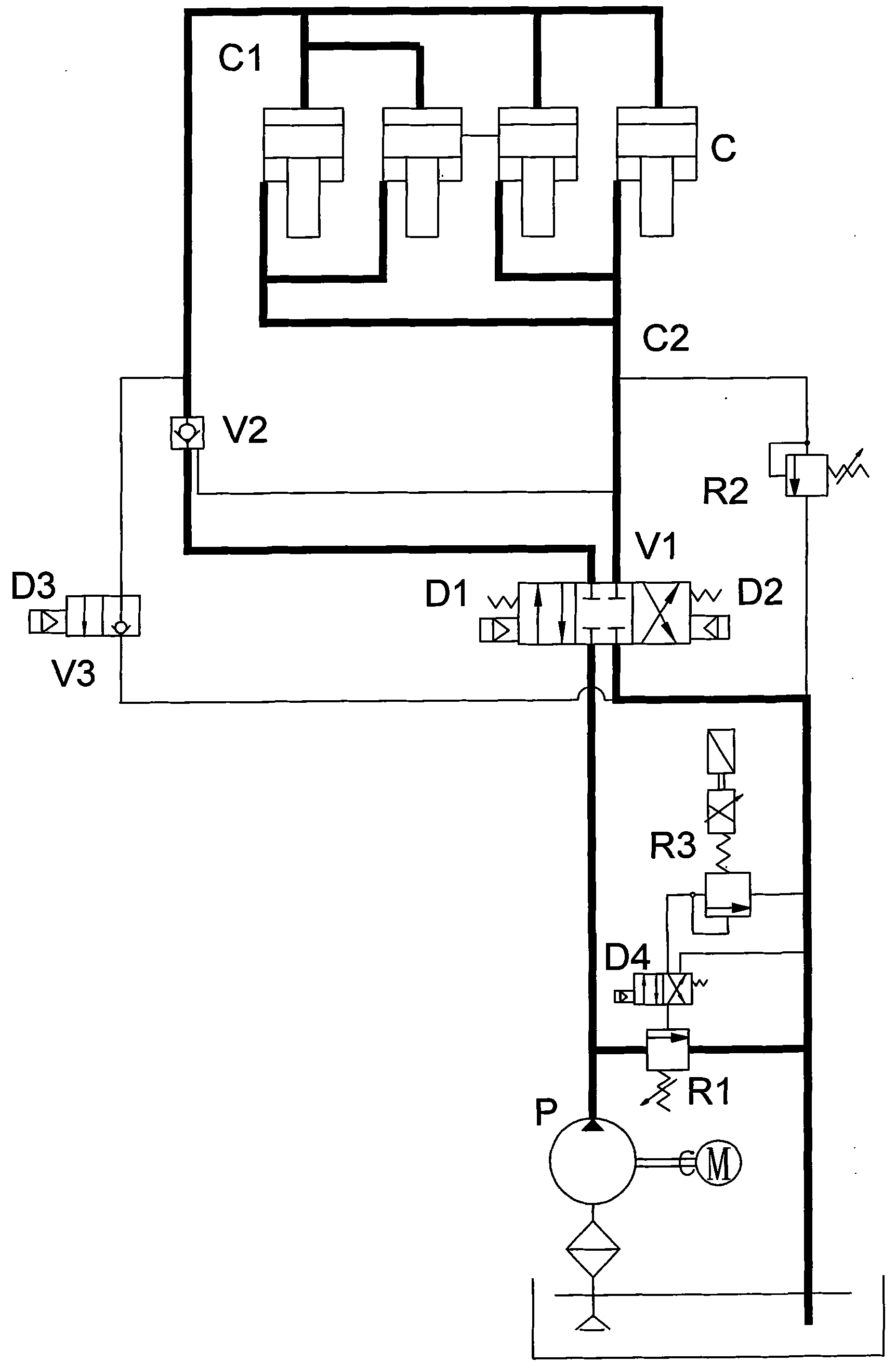

High pressure model-locked loop of double movable plate direct press injection machine

The invention relates to a high pressure die-locking circuit of a dual-motion plate direct pressure injection machine, comprising an oil pump which is driven by an electric motor, an electromagnetic reversing valve, an electromagnetic switch valve, overflow valves, a hydraulic control check valve and a high pressure die-locking oil cylinder; the electric motor drives the oil pump; the oil outlet of the oil pump is connected with the electromagnetic reversing valve; one working oil nozzle of the electromagnetic reversing valve is connected with the high pressure chamber of the high pressure die-locking oil cylinder through the hydraulic control check valve; another working oil nozzle of the electromagnetic reversing valve is connected with the recovery chamber of the high pressure die-locking oil cylinder; the oil outlet of the oil pump and the recovery chamber of the high pressure die-locking oil cylinder are both provided with the overflow valves; the non-rod chamber of the high pressure die-locking oil cylinder is connected with an oil tank through the electromagnetic switch valve. The proposal sufficiently considers the working characteristics of the dual-motion direct pressing injection machine and optimizes and simplifies the high pressure die-locking control oil path, and the invention is the high pressure die-locking circuit of the dual-motion direct pressing injection machine with more reasonable structure.

Owner:广东佳明机器有限公司

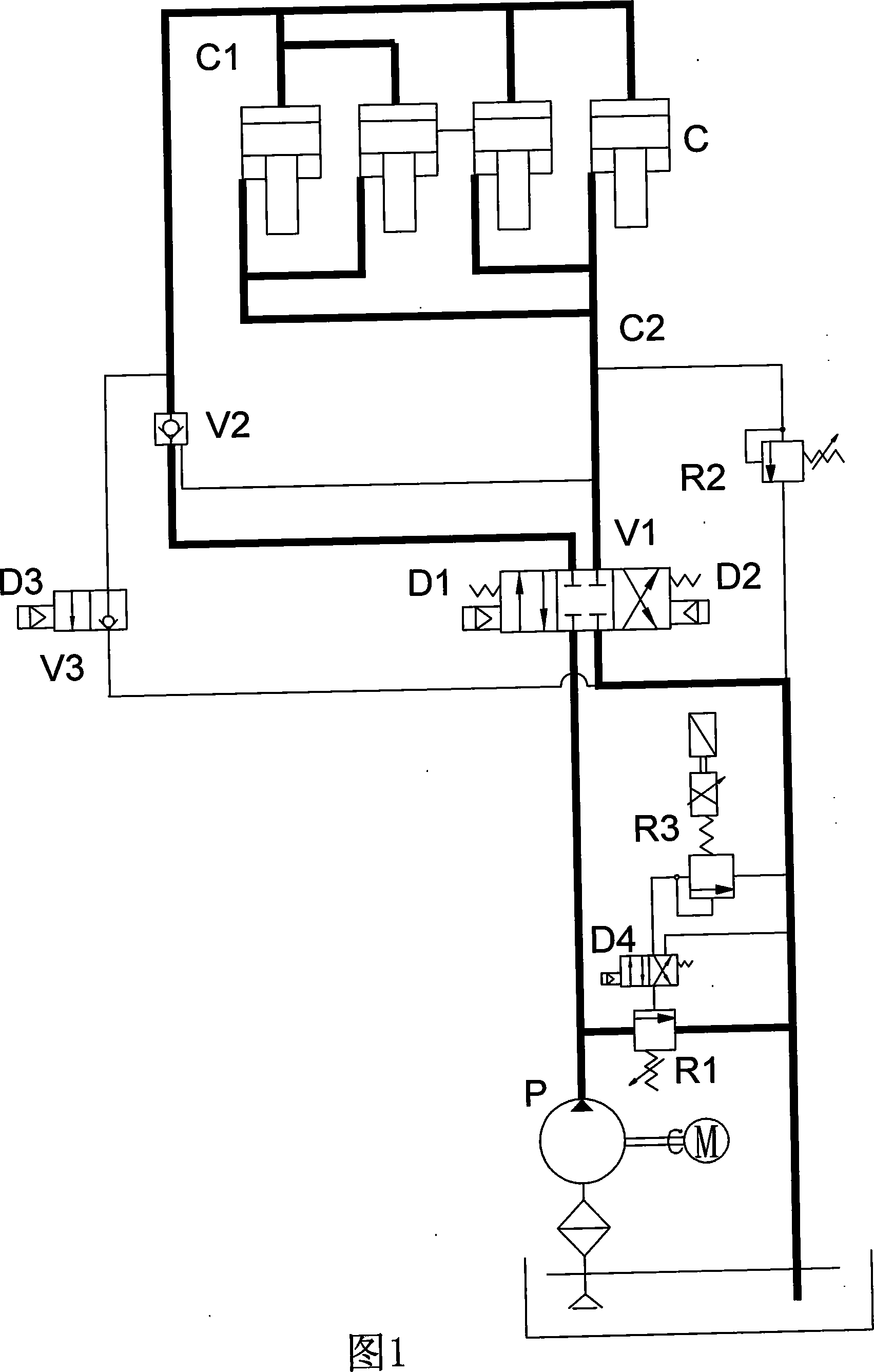

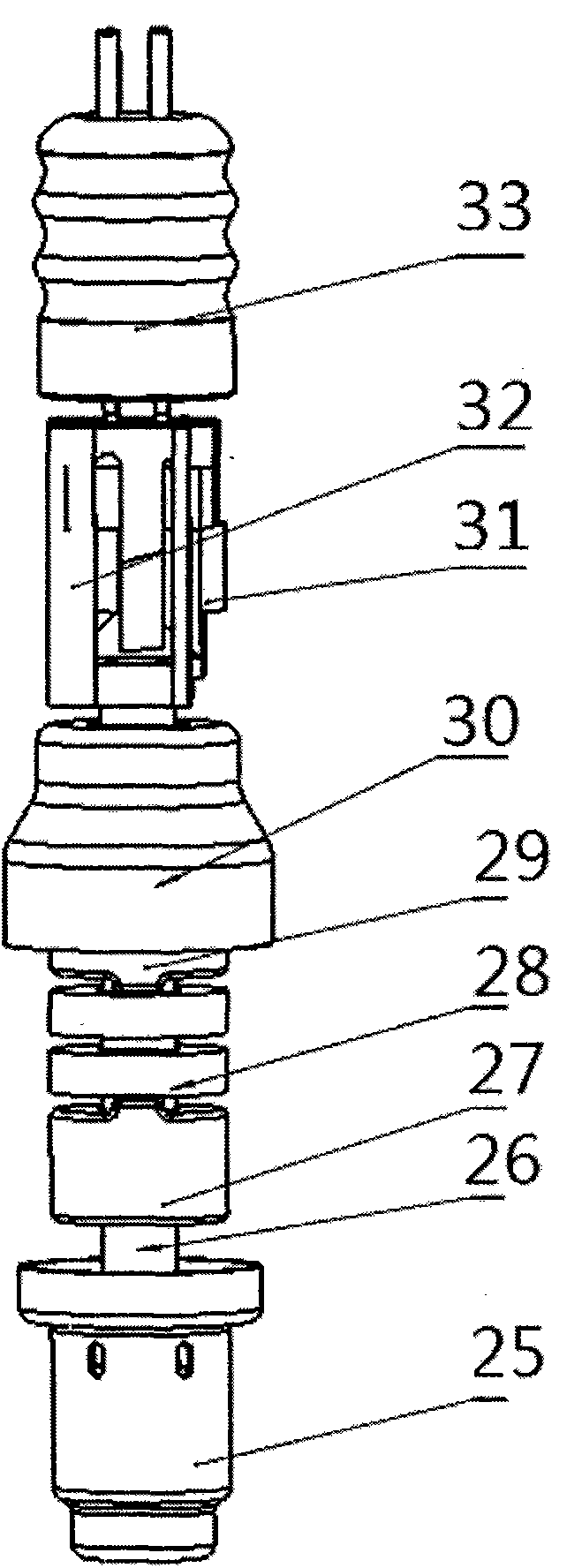

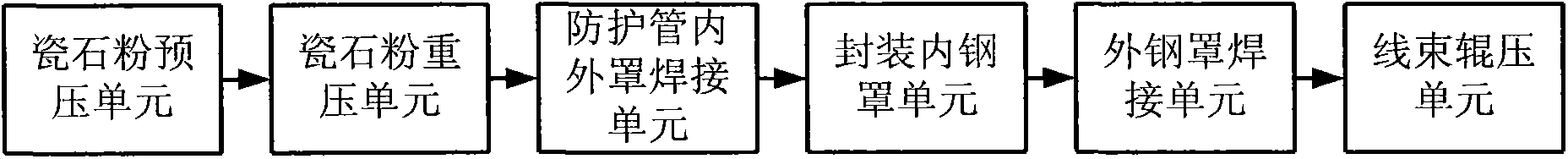

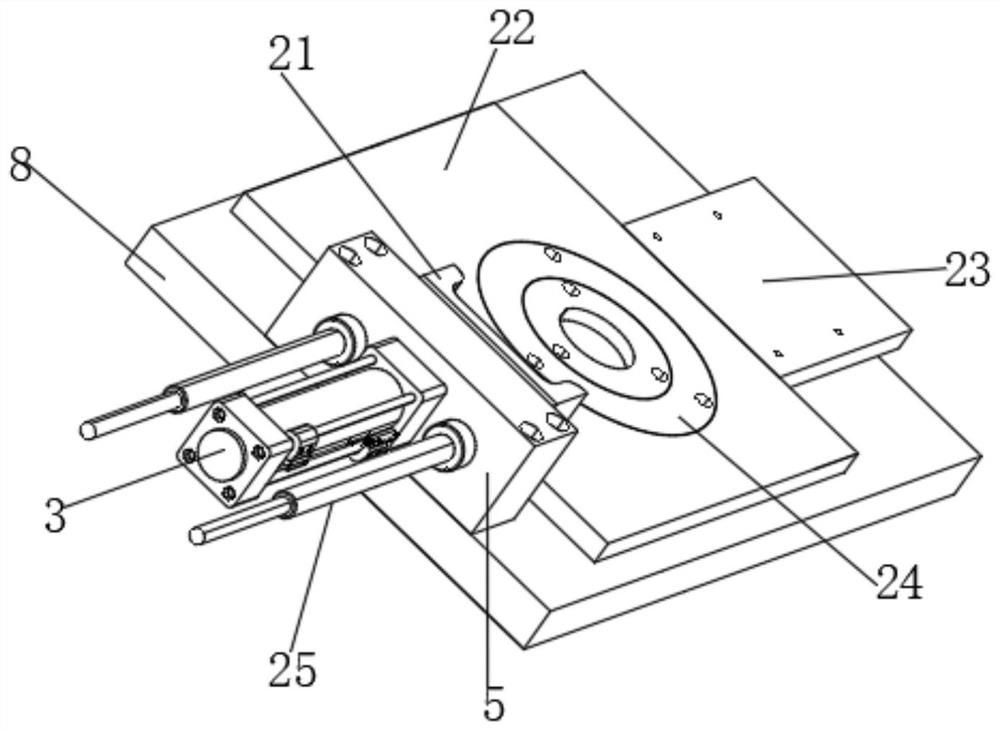

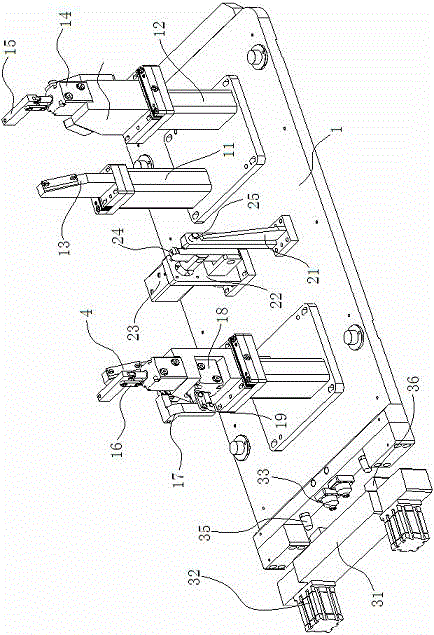

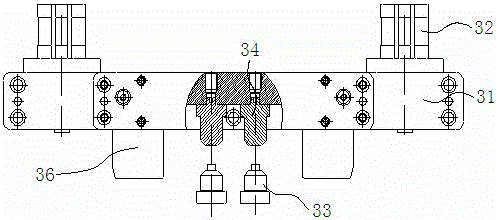

Automatic production line device for packaging oxygen sensor

ActiveCN103949891ARealize the assemblyIn line with the status quo of production technologyOther manufacturing equipments/toolsProduction lineOxygen sensor

The invention provides an automatic production line device for packaging an oxygen sensor. The automatic production line device comprises a China stone powder pre-pressing unit, a China stone powder repressing unit, a protective inner and outer cover welding unit, an inner steel cover packaging unit, an outer steel cover welding unit and a wire harness rolling unit, wherein the structures of the protective inner and outer cover welding unit and outer steel cover welding unit are the same, a laser beam is used for welding a protective pipe inner cover, a protective pipe outer cover and an outer steel cover with a hexagonal base together so as to protect an interior sensor chip. According to the automatic production line device, the units are sequentially connected according to the assembling technology of the oxygen sensor, and semi-automatic and full-automatic assembling of the oxygen sensor product is realized, so that the product quality can be stabilized and improved, the working conditions are improved, the occupied area for production is reduced, the production cost is reduced, and the production cycle is shortened.

Owner:WENZHOU UNIVERSITY

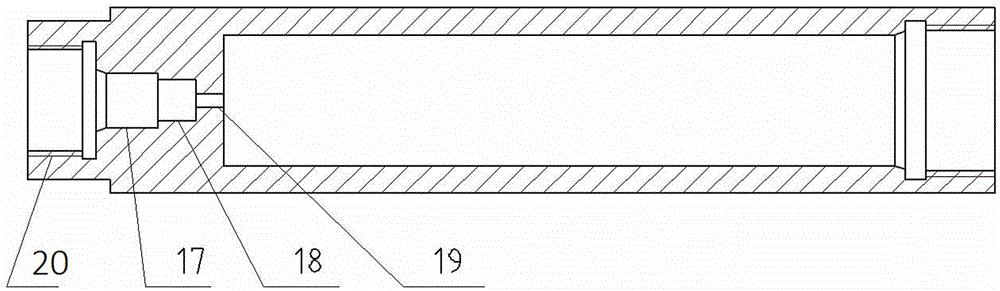

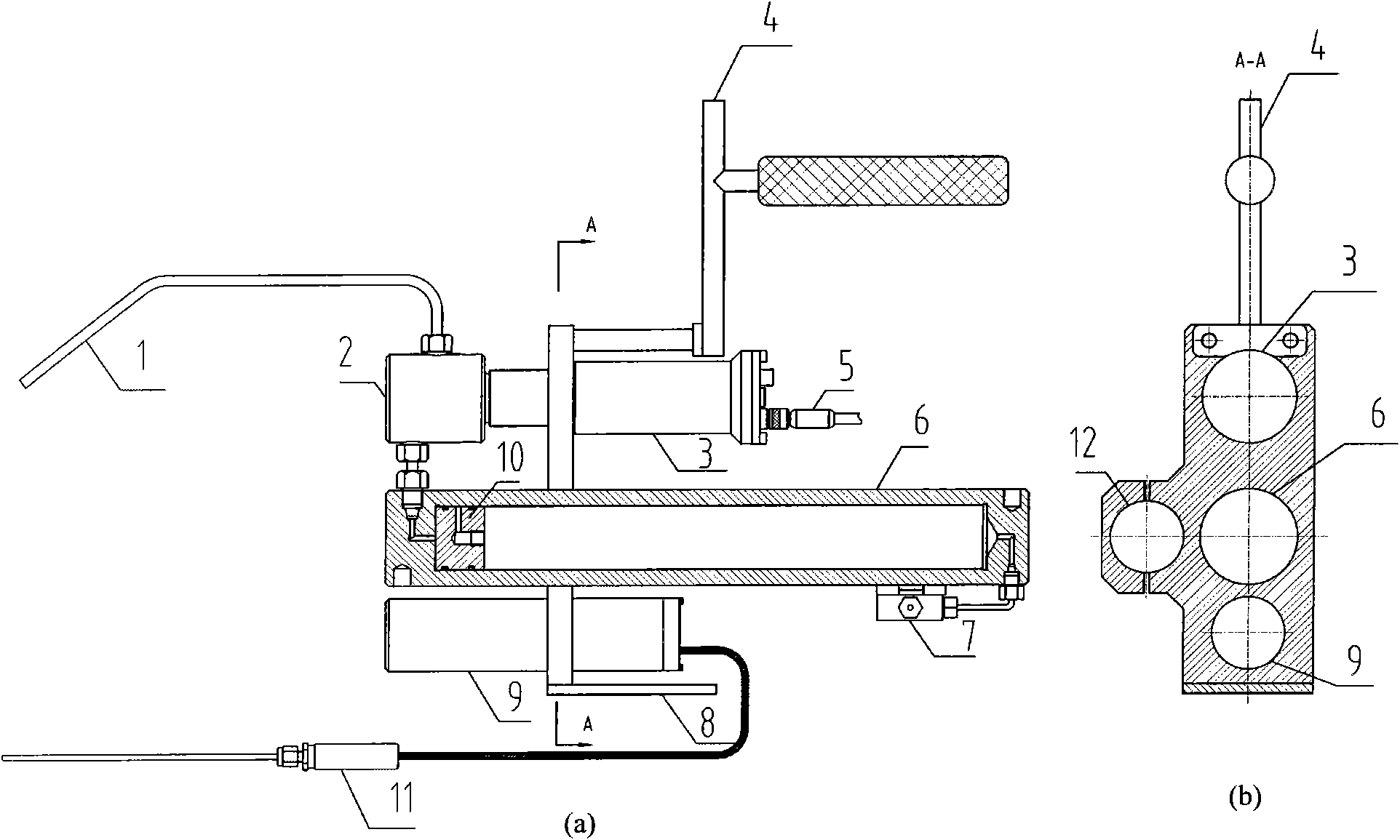

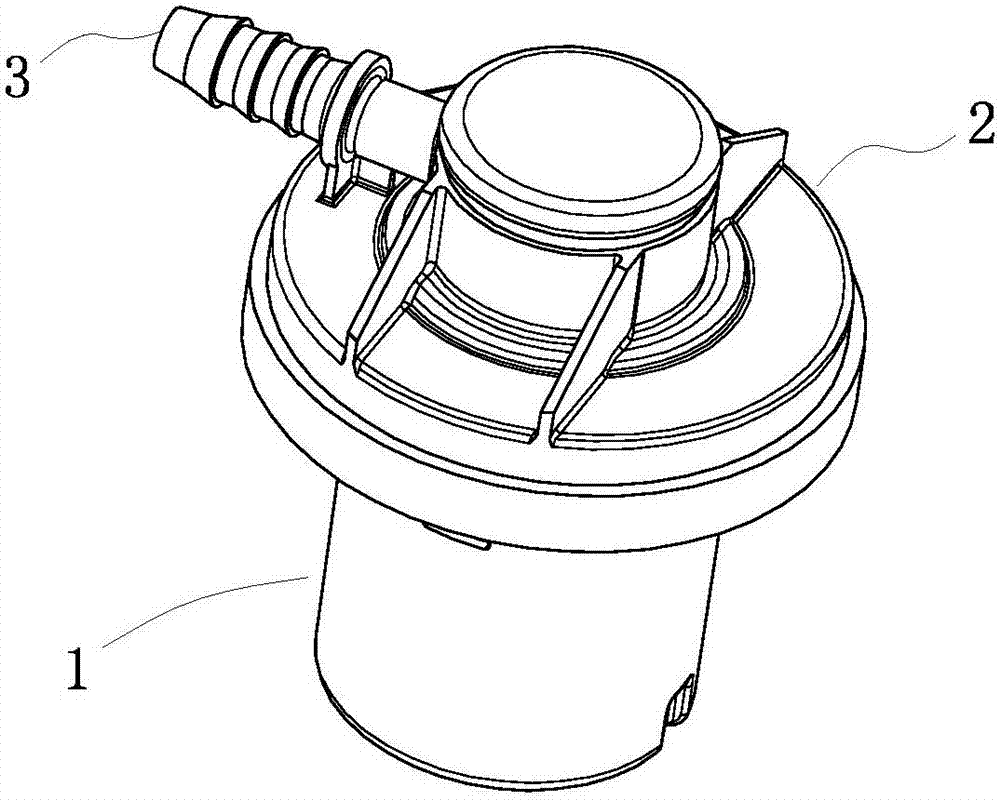

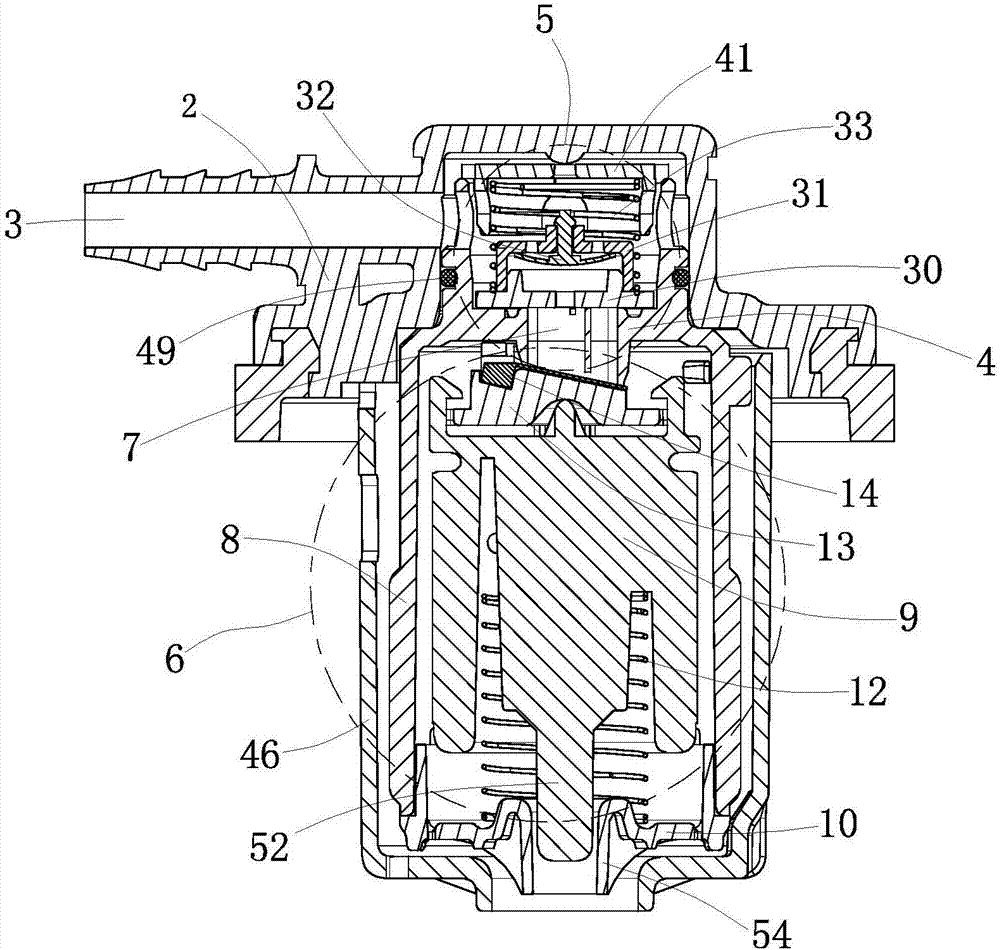

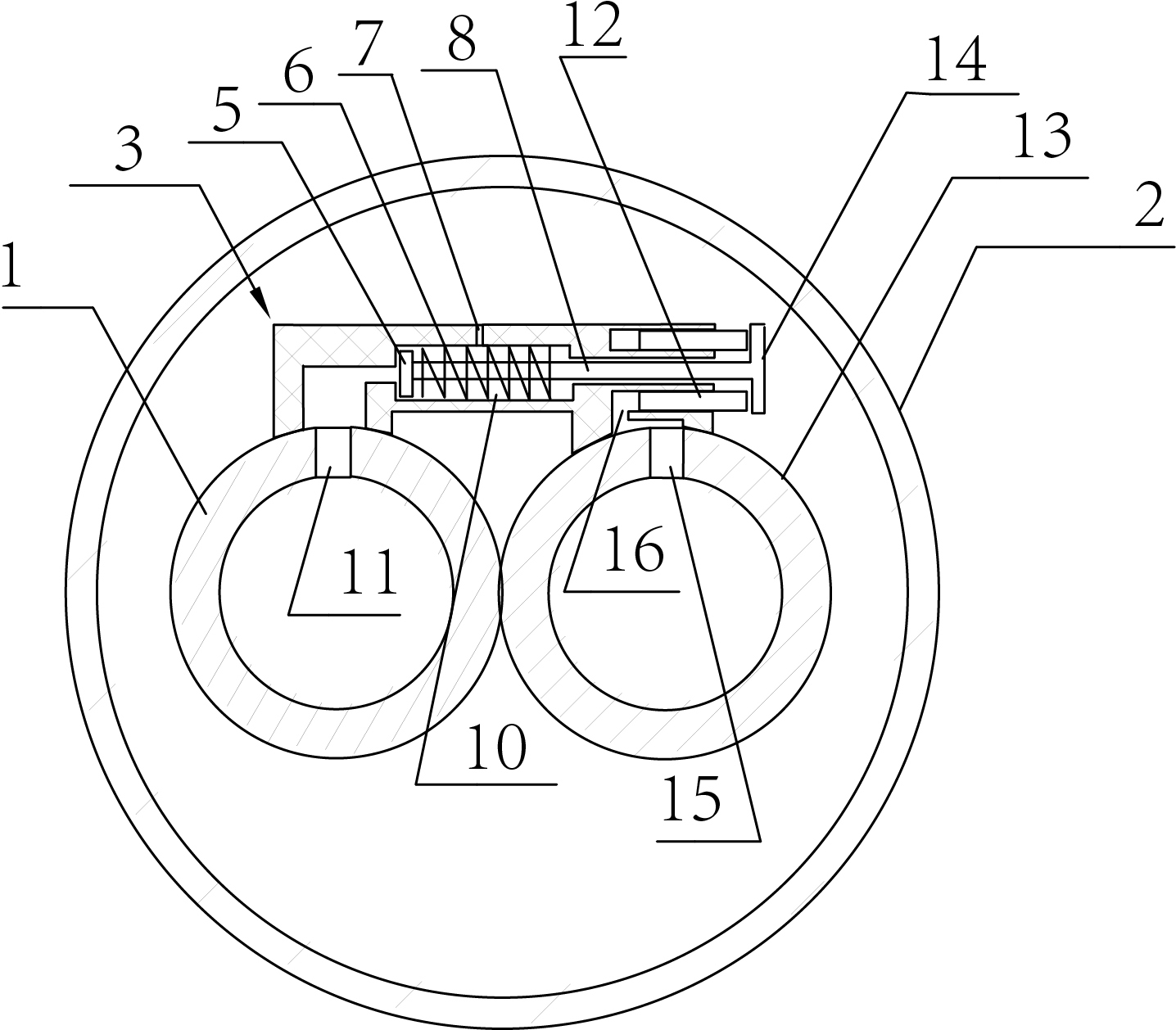

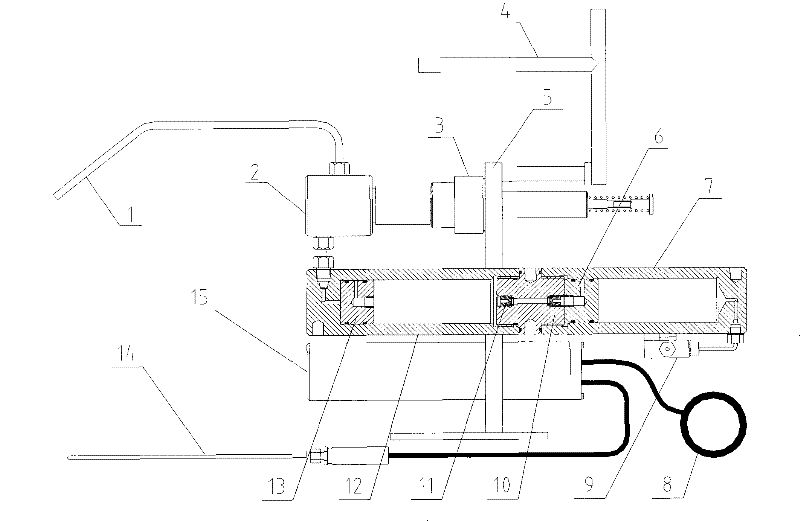

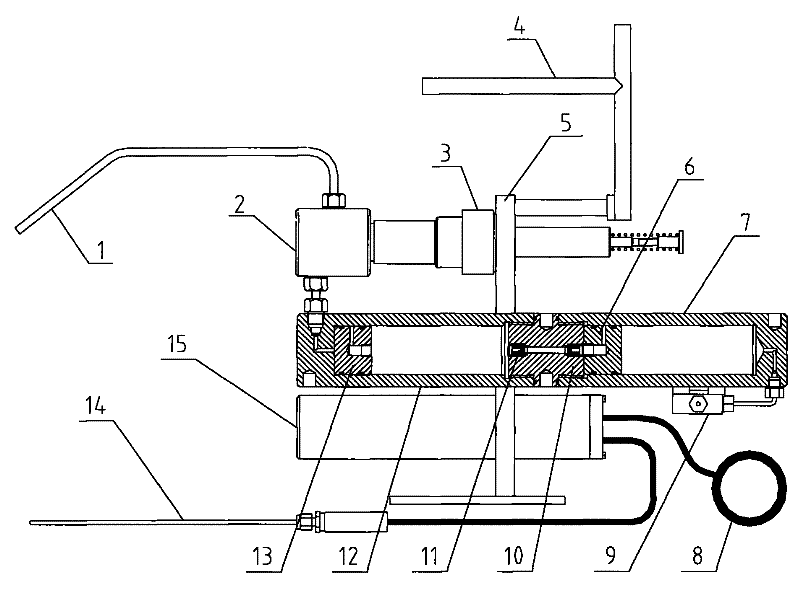

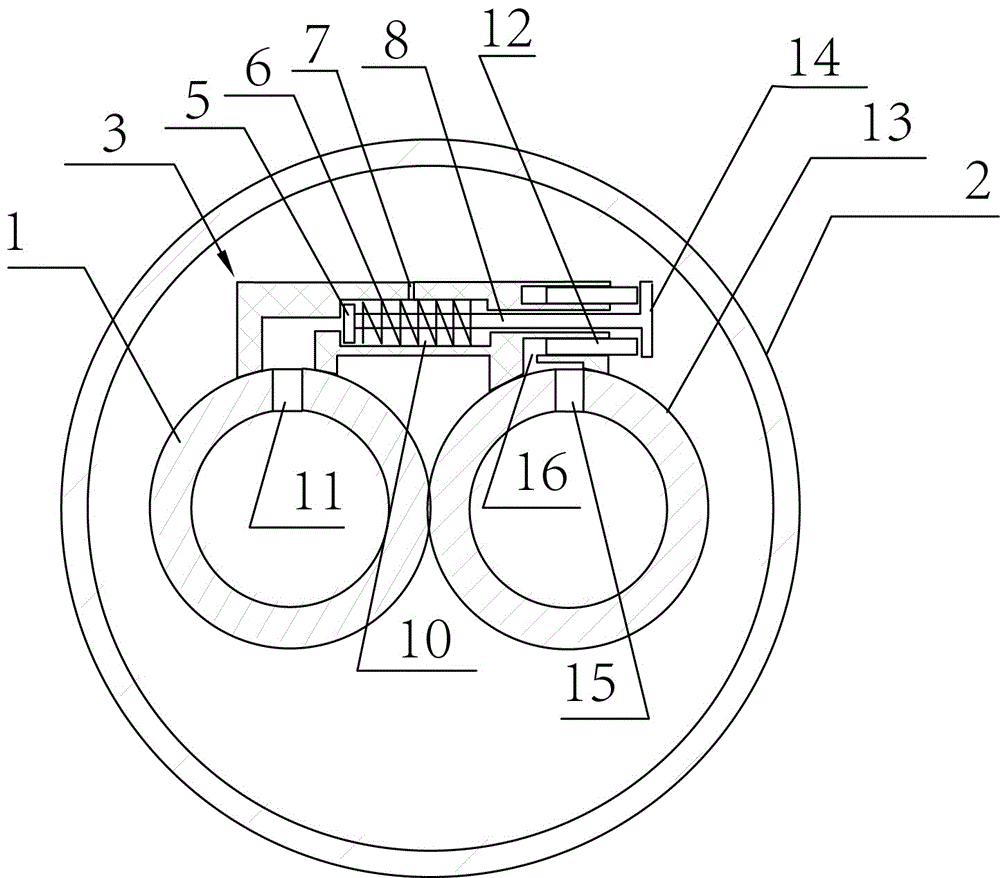

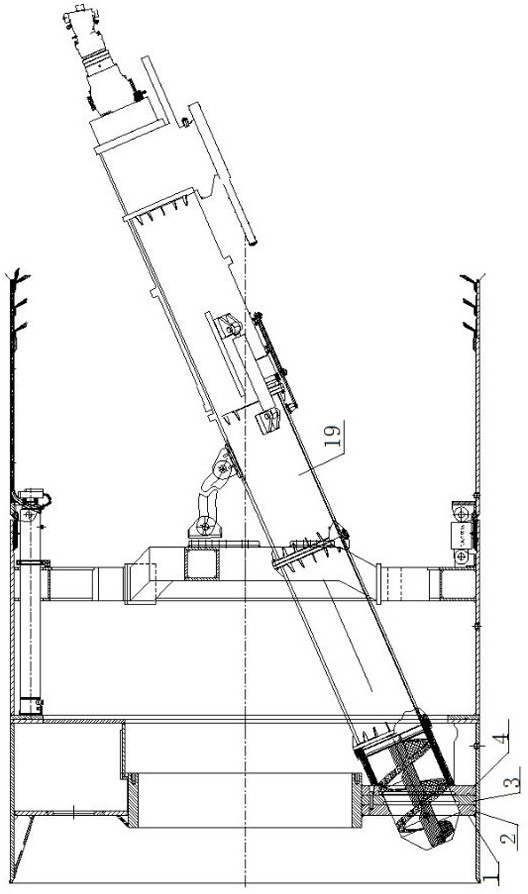

Automatic sampler of submarine hydrothermal solution

InactiveCN101975682AGood pressure retentionCompact structureThermometer detailsWithdrawing sample devicesShallow seaManipulator

The invention discloses an automatic sampler of submarine hydrothermal solution, comprising an opened valve cavity, a sampling cavity, a temperature measuring circuit cavity, and a temperature displaying circuit cavity, which are arranged on a support. In the sampler of the invention, an electronic-controlled trigger mechanism arranged in the opened valve cavity is used for controlling the sampling valve to realize the automatic sampling. The sampler can measure and display the temperature of the hydrothermal solution in real time during the sampling process, thereby facilitating the finding of the optimal sampling point. The sampler has compact overall structure and small size, is suitable for the operation of a diver or a bathyscaphe manipulator, and can meet the requirement of hydrothermal solution sampling in the shallow sea and the deep sea.

Owner:ZHEJIANG UNIV

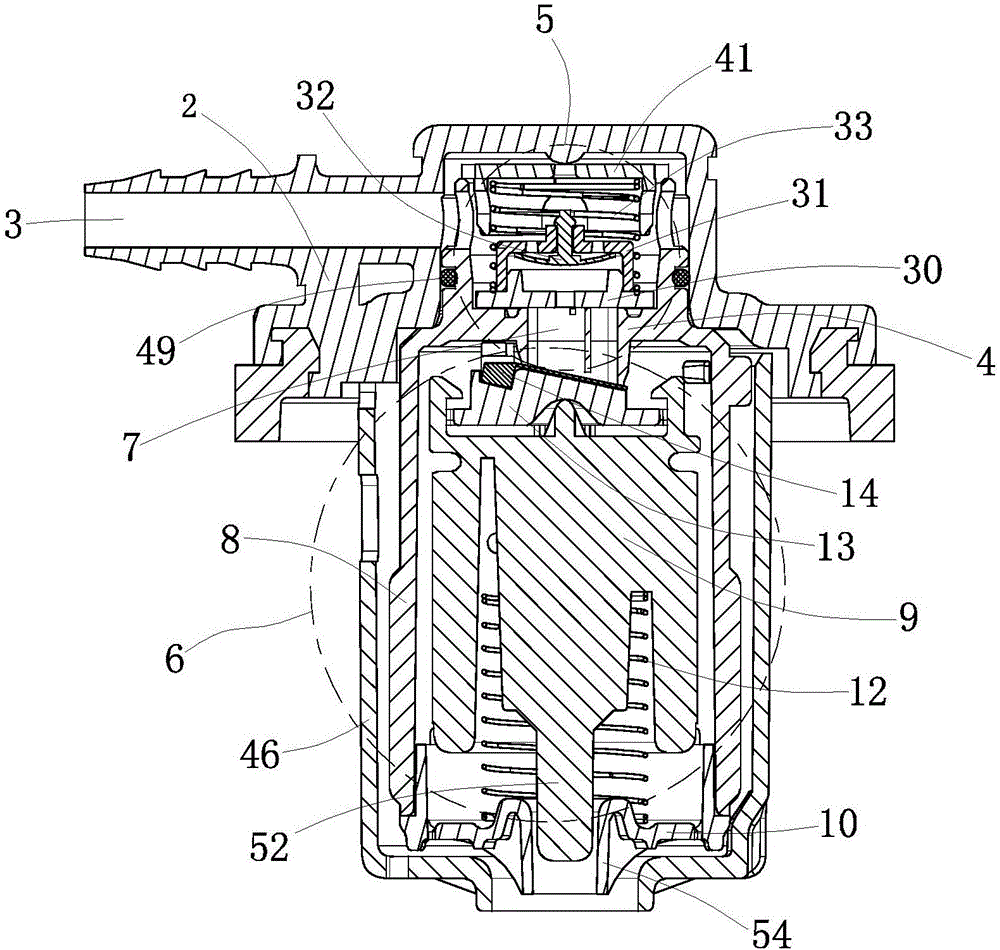

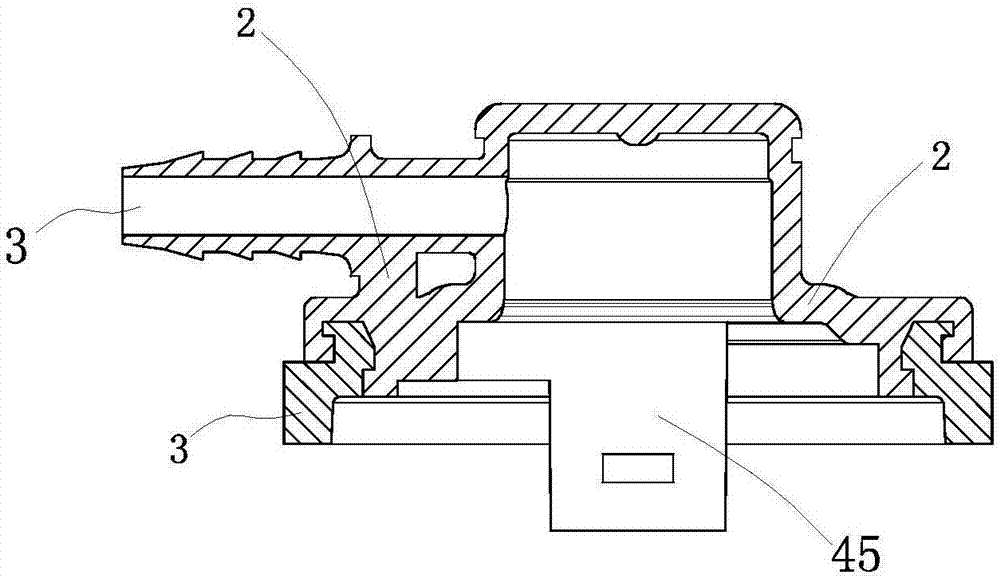

Ventilation stop valve

InactiveCN106812984AImprove job stabilityImprove controllabilityEqualizing valvesSafety valvesExhaust valveEngineering

The invention provides a ventilation stop valve. The ventilation stop valve comprises a valve body (1) and a valve cover (2); the valve body (1) includes a shell (8) provided with an isolation wall (4) inside, a ventilation valve (5) positioned above the isolation wall (4), and a stop valve (6) positioned below the isolation wall (4); the ventilation valve (5) includes a pressure maintaining base (30), a pressure maintaining cover (31), an umbrella-shaped rubber piece (32) and a pressure maintaining spring (33); an upper convex ring (18) is arranged on the isolation wall (4), and is provided with a small gap (19); the ventilation valve includes an independent one-way exhaust valve and an independent one-way air replenishing valve; the working stability and the controllability of the ventilation valve are improved; and the pressure maintaining performance of the pressure maintaining mechanism is better.

Owner:慈溪市华龙电子有限公司

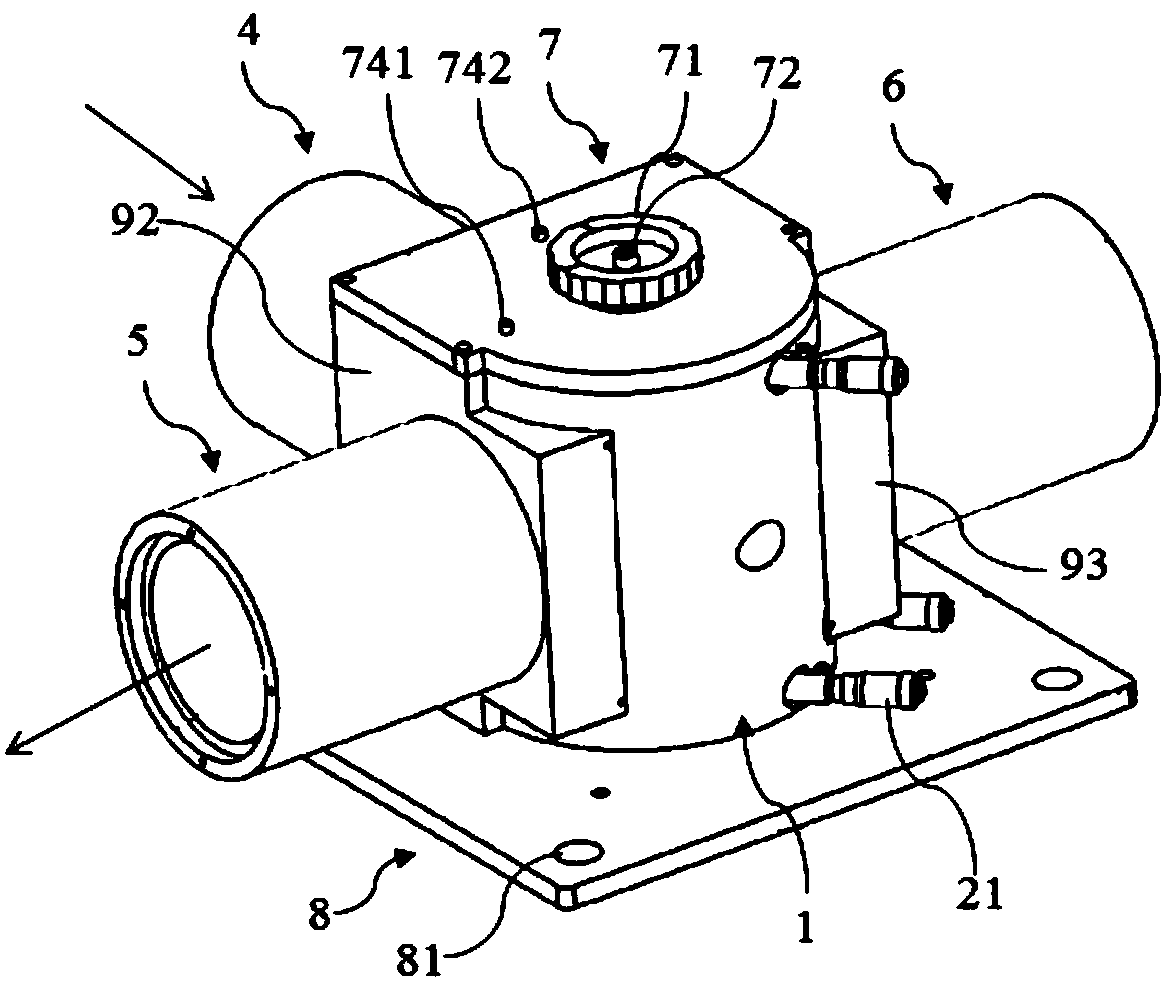

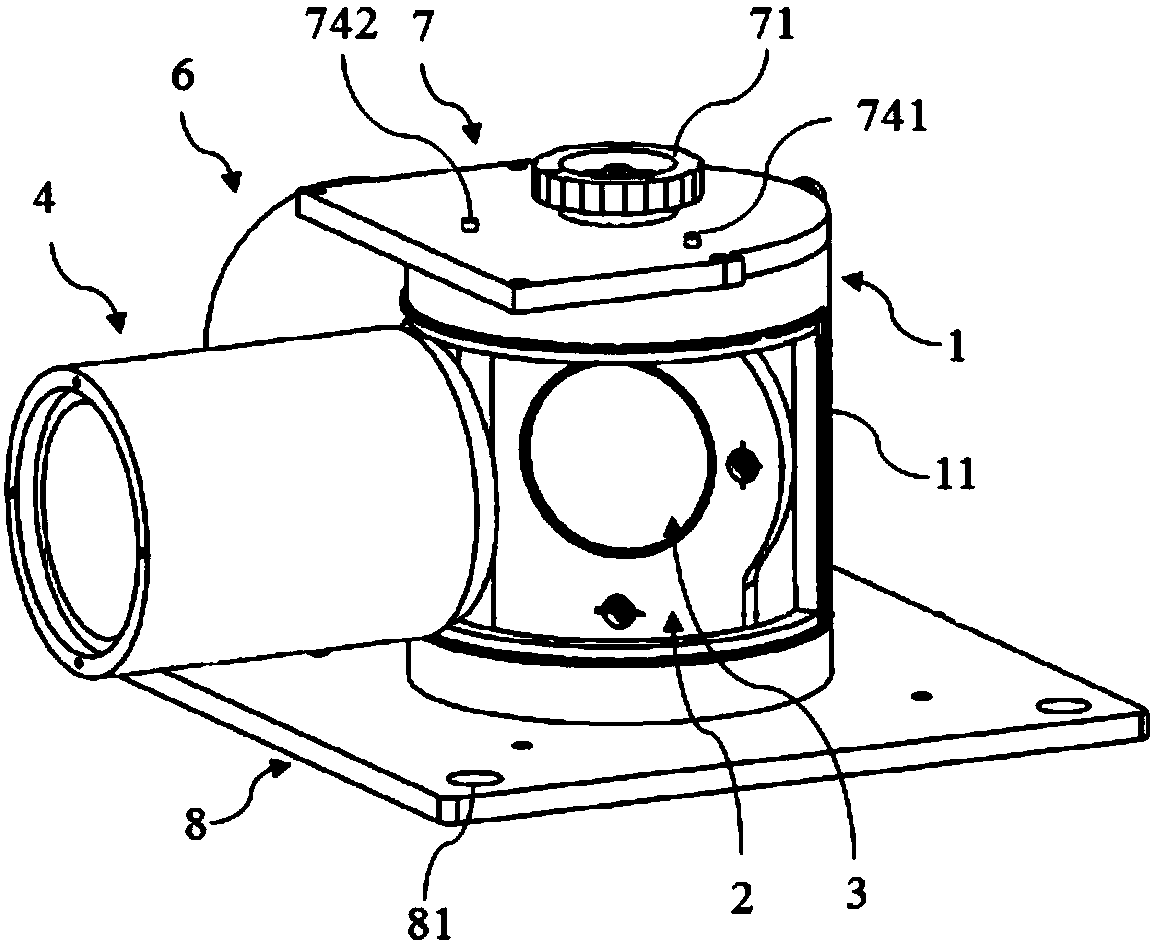

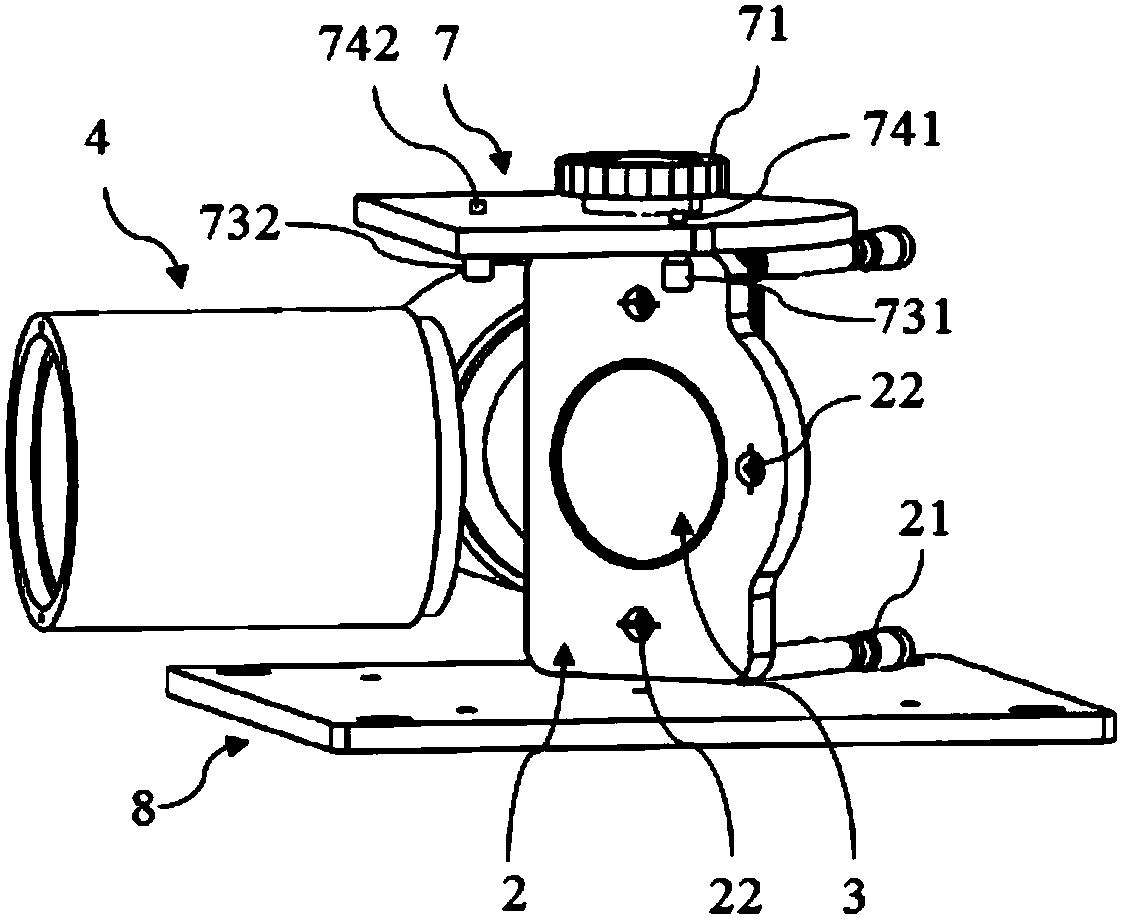

Optical path transmitting and reversing device and optical performance parameter detection system

PendingCN108106999AQuick switchGood pressure retentionMaterial analysis by optical meansEngineeringHollow cylinder

The invention provides an optical path transmitting and reversing device. The optical path transmitting and reversing device comprises a input light cylinder, a reversing cylinder, an optical bracket,a first output light cylinder, a second output light cylinder, a top plate and a bottom plate, wherein the reversing cylinder is a partially hollow cylinder; the reversing cylinder is fixedly mountedon the bottom plate; the optical bracket is mounted inside the reversing cylinder; a reflector is fixedly mounted on the optical bracket; multiple side plates connected with the input light cylinder,the first output light cylinder and the second output light cylinder respectively are arranged around the reversing cylinder; the top plate is mounted on the top of the reversing cylinder; a turnplate capable of rotating the reversing cylinder is arranged on the top plate; a limiting mechanism is further arranged on the top plate, and the limiting mechanism can limit the optical bracket to be ina first state or a second state different from the first state. The invention further provides an optical performance parameter detection system comprising the optical path transmitting and reversingdevice.

Owner:ACAD OF OPTO ELECTRONICS CHINESE ACAD OF SCI

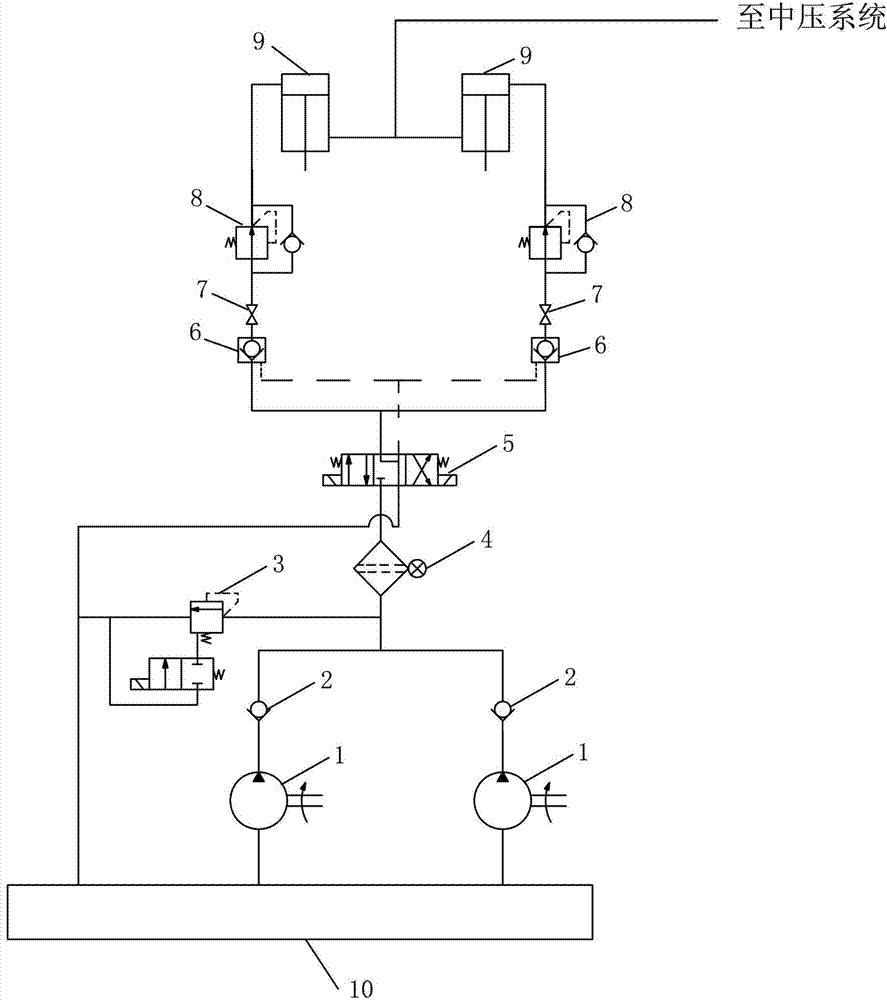

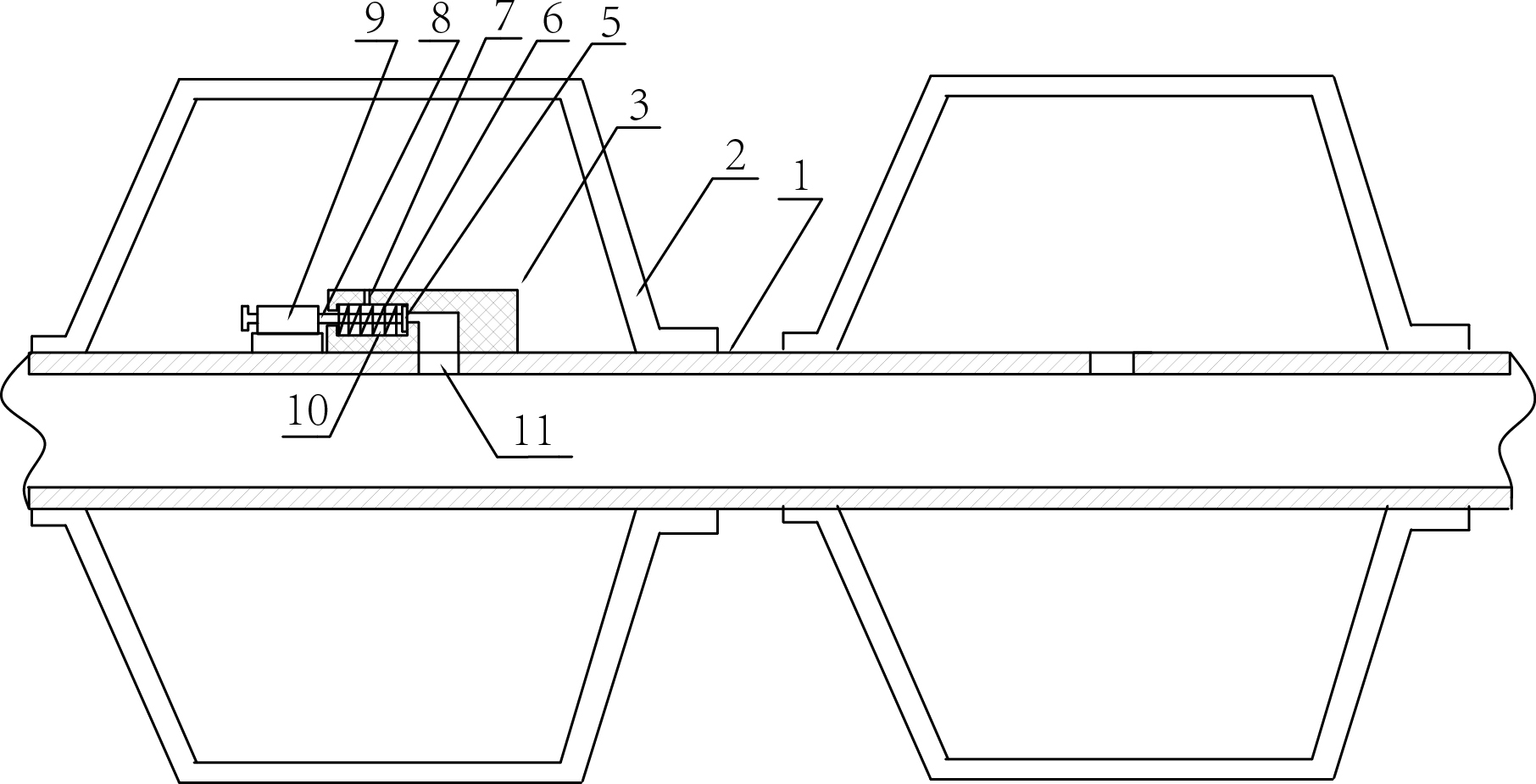

Dual-roll rolling machine hydraulic pressing down system and operation method thereof

InactiveCN103111471AGood pressure retentionReduce consumptionRoll force/gap control deviceSystem pressureThrottle

The invention relates to a dual-roll rolling machine hydraulic pressing down system and an operation method thereof and belongs to the technical field of hydraulic system pressurizing. The system comprises two symmetrical oil circuits. Each oil circuit comprises a plunger pump, a pressing down oil cylinder, an electromagnetic overflow valve, a one-way valve, a filter, an energy accumulator, an electromagnetic ball valve, a throttling valve, a first one-way throttling valve, a pressure sensor and the like. Due to the fact that the one-way valve, a hydraulic one-way valve and the electromagnetic ball valve in the work circuit of the hydraulic pressing down system is good in pressurizing performance and the energy accumulator can supplement system pressure, the system is long in pressurizing time, stable in pressure and reliable in pressurizing. In the mean time, a plunger stops during pressurizing, up and down waving of pressure during operation is eliminated completely, plate shape quality is improved greatly, and power consumption during production is saved.

Owner:浙江远景铝业有限公司

Vent shut-off valve

InactiveCN106949275AImprove job stabilityImprove controllabilityOperating means/releasing devices for valvesEqualizing valvesEngineeringRubber sheet

Provided is a vent cut-off valve, comprising a valve body (1) and a valve cover (2), the valve body (1) comprising a casing (8) with a partition wall (4) inside and a ventilator located above the partition wall (4). Valve (5), the cut-off valve (6) positioned at the bottom of the partition wall (4), the partition wall (4) offers a fluid channel hole (7), the bottom is provided with a floating core (9), and the top of the floating core (9) is in contact with the partition wall ( 4) There is a sealing mechanism between them, the sealing mechanism includes a sealing seat (13) and a rubber sealing sheet (14) installed on the floating core (9), an arc boss (15) is arranged on the floating core (9), the sealing seat (13) The corresponding arc recesses (16) for inserting the arc bosses (15) are provided below, so that the sealing seat (13) can flexibly swing in any direction, and the rubber sealing sheet (14) passes through the fixing buckle (27) Installed on the sealing seat (13), a small gap (19) is provided on the upper convex ring (18) of the partition wall (4); the sealing performance and stability are improved, and the pressure maintaining performance of the pressure maintaining mechanism is better.

Owner:慈溪市华龙电子有限公司

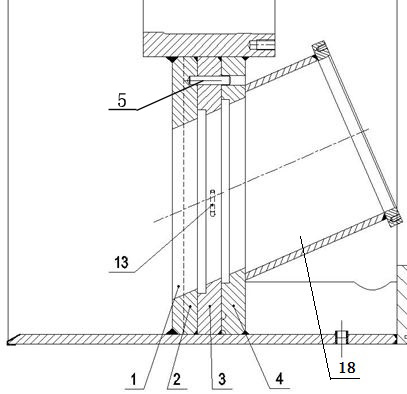

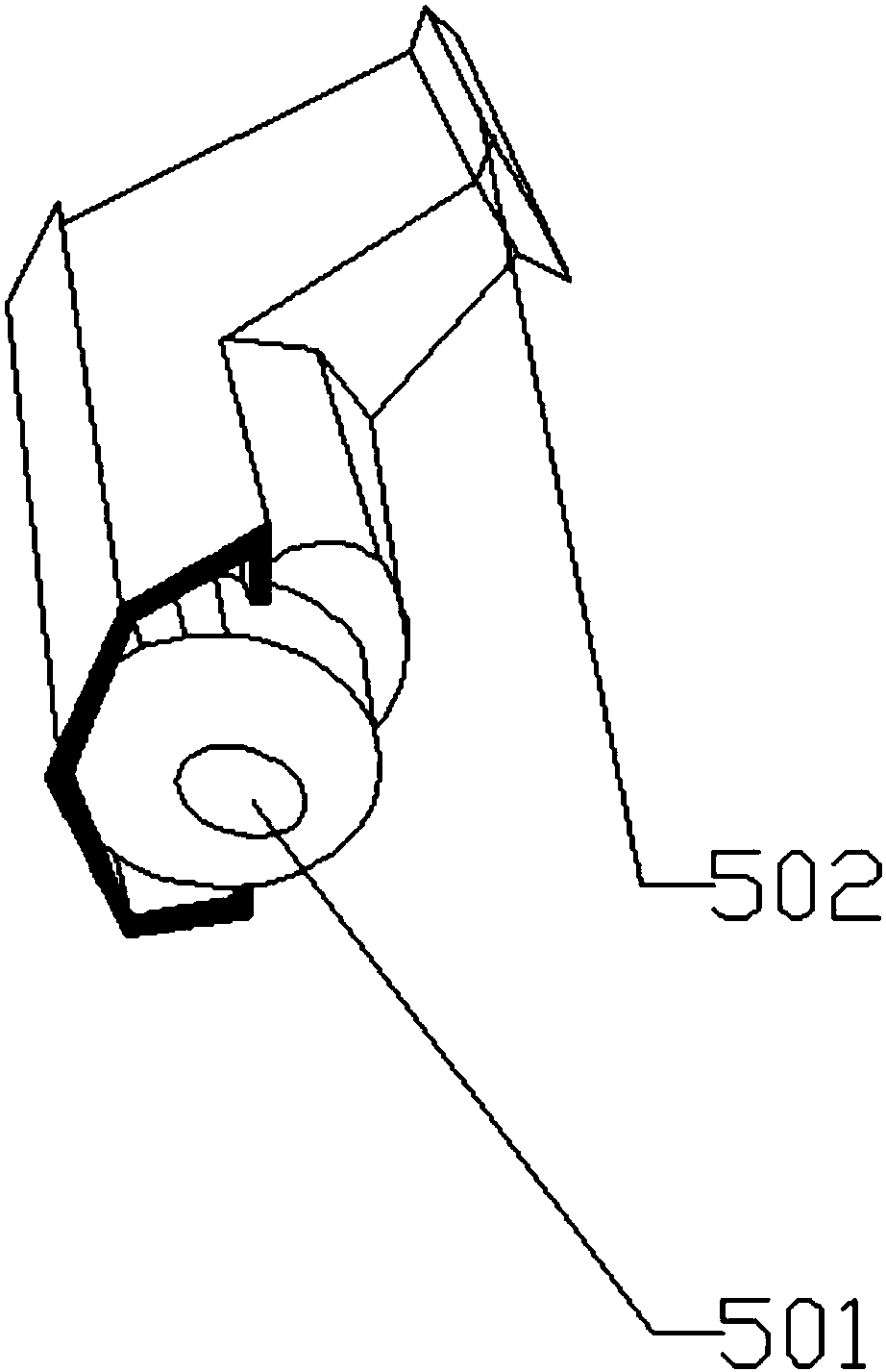

Gas-liquid balancing device for vertical ram milling head

ActiveCN103302548AAvoid mechanical accidentsGood pressure retentionMechanical apparatusMaintainance and safety accessoriesSafety valveMachine tool

The invention provides a gas-liquid balancing device for a vertical ram milling head, which can realize balance of a machine ram. The invention adopts the following technical scheme that the gas-liquid balancing device for the vertical ram milling head comprises two balancing cylinders, an energy accumulator and an overflowing and throttling structure; the two balancing cylinders are respectively arranged on both sides of the ram milling head; the energy accumulator is simultaneously connected with oil outlet pipelines of the two balancing cylinders through a main pipeline by a three-way connecting mechanism; the energy accumulator is provided with an oil drainage branch circuit; the overflowing and throttling structure comprises a safety valve, a first control valve and a second control valve; the safety valve and the first control valve are arranged on the oil drainage branch circuit; and the second control valve is arranged on the main pipeline.

Owner:JIER MACHINE TOOL GROUP

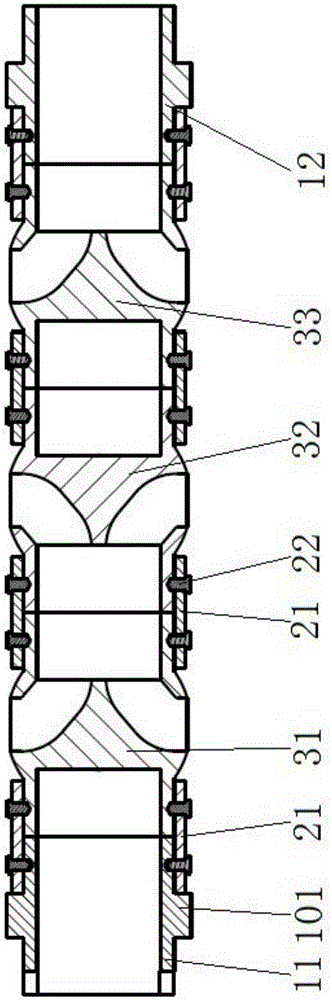

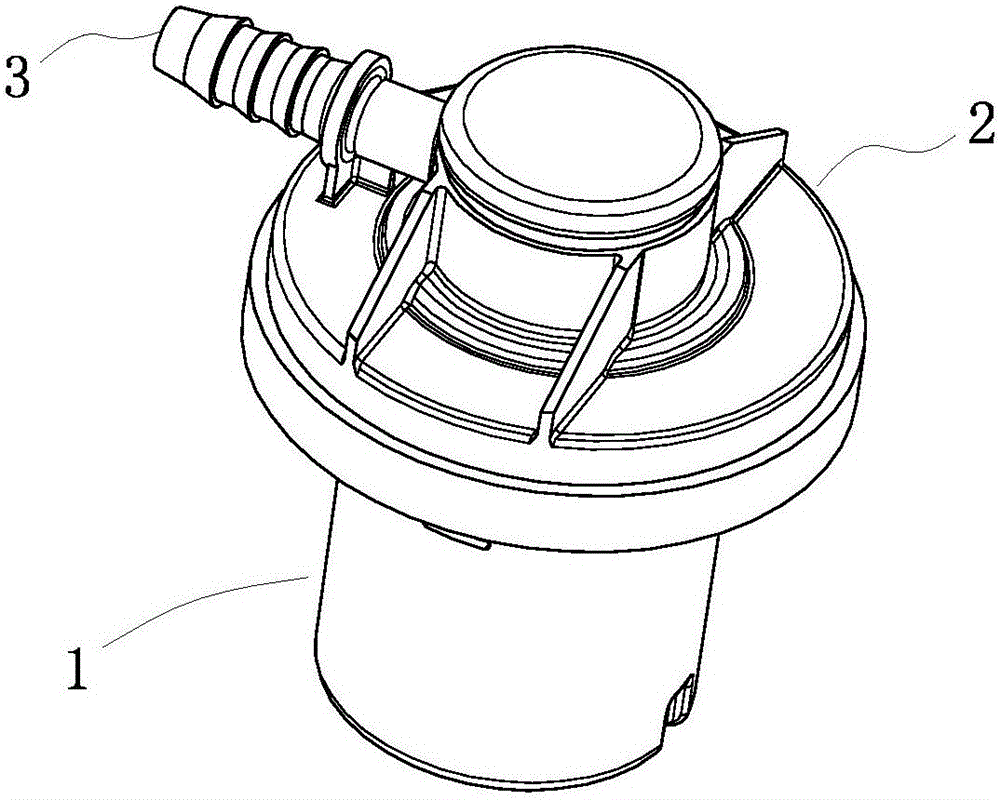

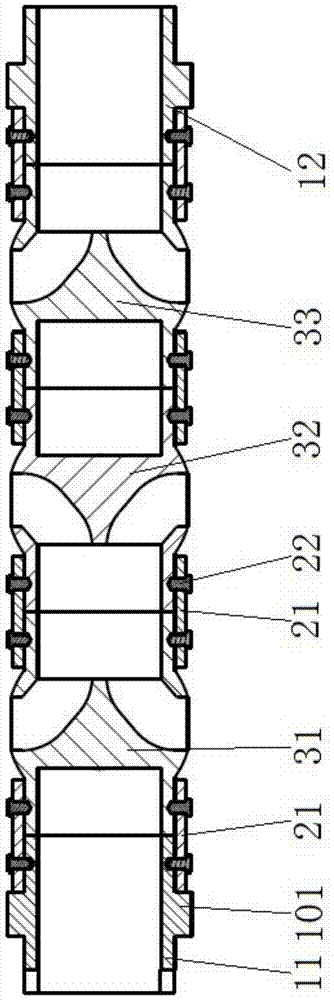

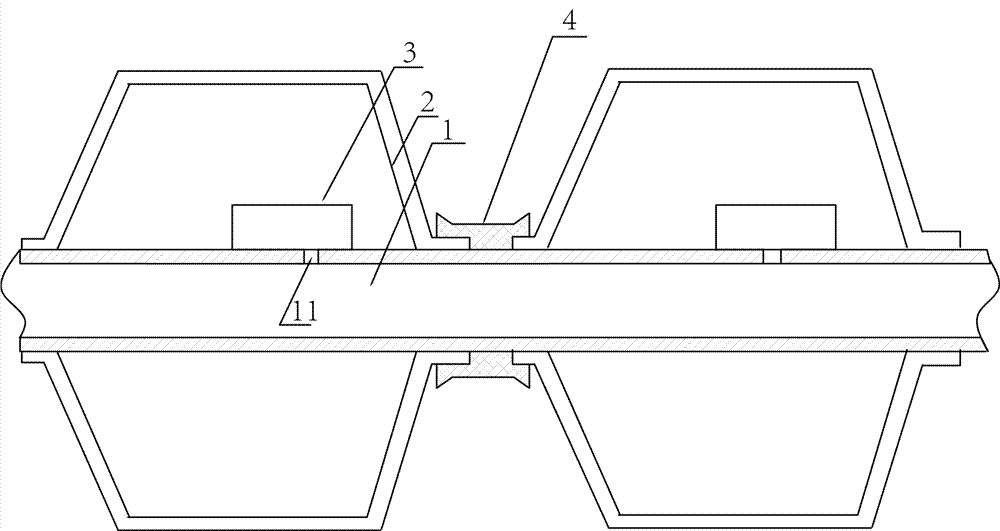

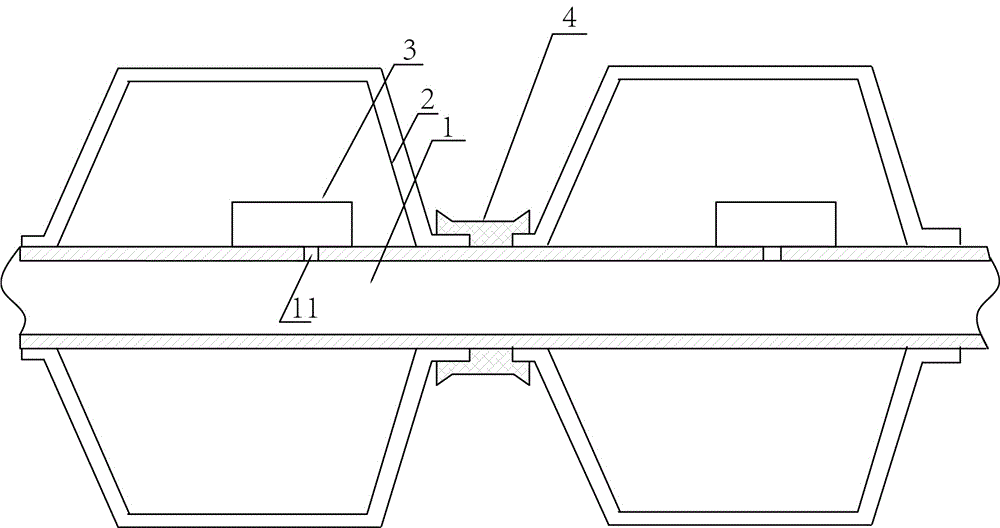

Series-connected air bag

InactiveCN102658857AGood pressure retentionMeet pressure retentionWaterborne vesselsSpecial purpose vesselsEngineeringMechanical engineering

The invention relates to a series-connected air bag. The series-connected air bag comprises an inflation / deflation main pipe (1) and a plurality of air bag units (2) which are sequentially arranged along the inflation / deflation main pipe (1), wherein each air bag unit (2) respectively comprises an inflation / deflation control device (3), and each inflation / deflation control device (3) is respectively connected with an inflation / deflation hole (11) on the inflation / deflation main pipe (1). Inflation and deflation are completed through one main pipe. The series-connected air bag disclosed by the invention has simpler arrangement of a pipeline and can enable the series connection to be long enough according to needs. When more than one of the air bag units has air leakage, the other air bag units are not affected, thus the normal use of the whole series-connected air bag can be ensured.

Owner:吉昌辉

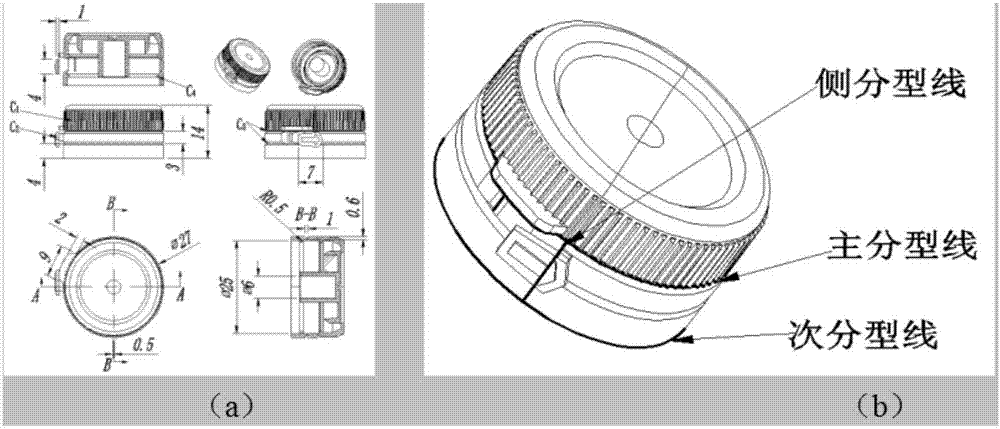

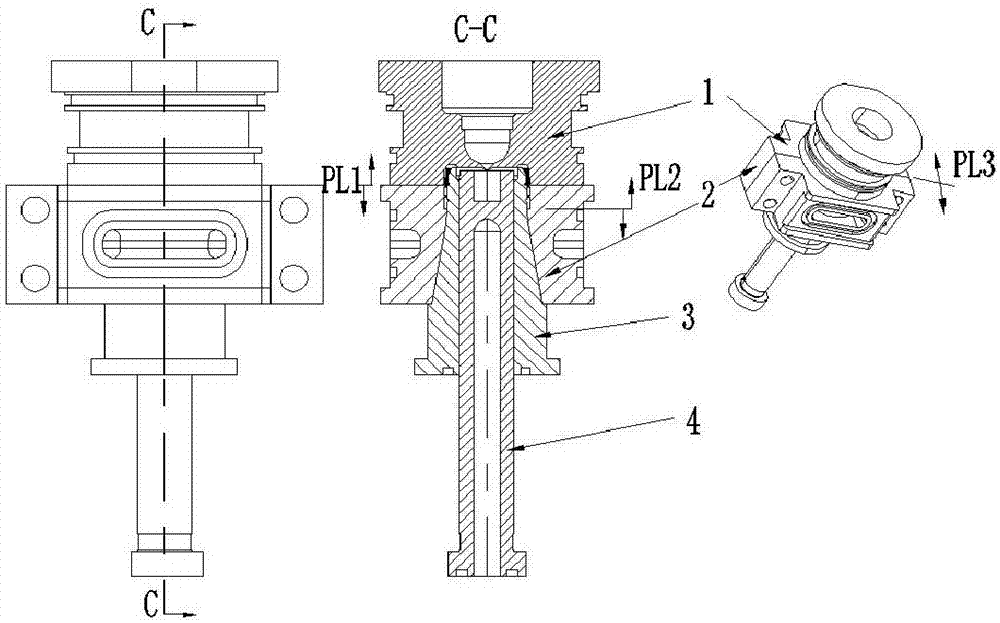

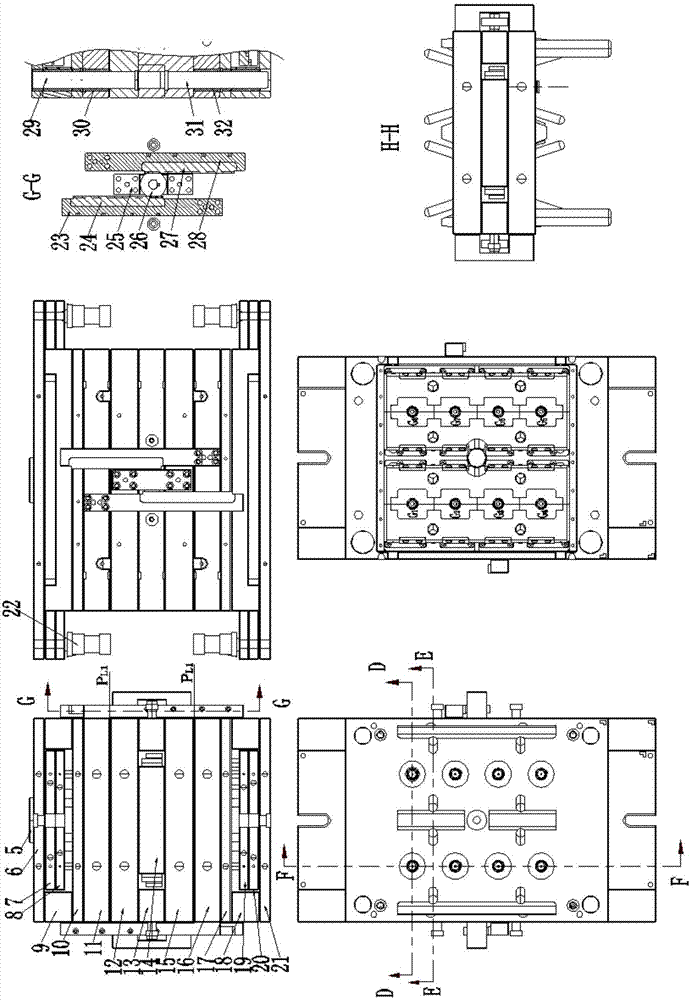

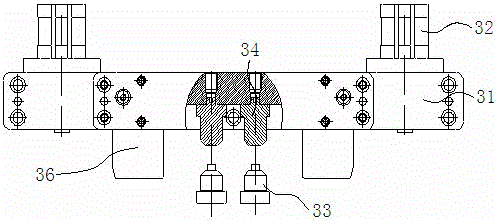

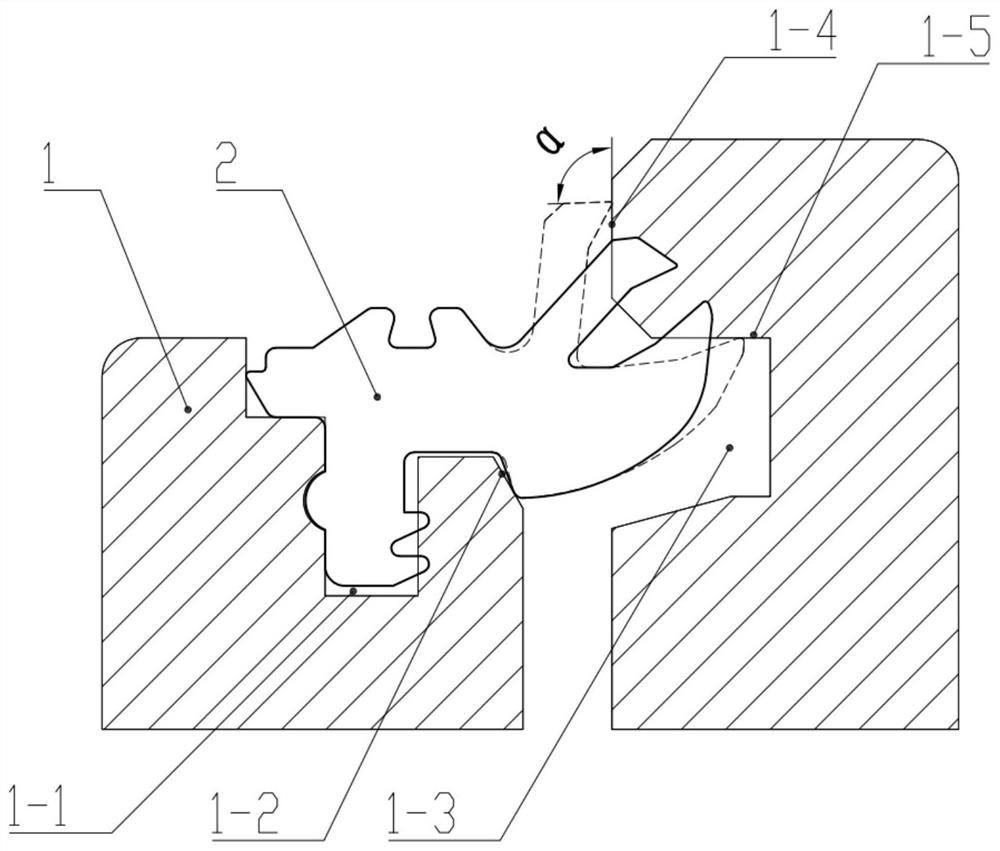

Drug testing reagent kit and manufacturing method thereof

InactiveCN107984699ASimple organizationGuarantee molding qualityDomestic articlesHot runnerBiomedical engineering

The invention relates to the field of medical instrument design and particularly relates to a drug testing reagent kit and a manufacturing method thereof. The drug testing reagent kit comprises a kitbody, a kit cover, a holder, a sleeve, a reagent bottle and a bottle cap, wherein the bottle cap is manufactured by using a bottle cap stack mold type hot runner injection mold. The air tightness andaging resistance of the bottle cap of the reagent bottle, manufactured by the bottle cap stack mold type hot runner injection mold, are greatly improved.

Owner:刘云梦

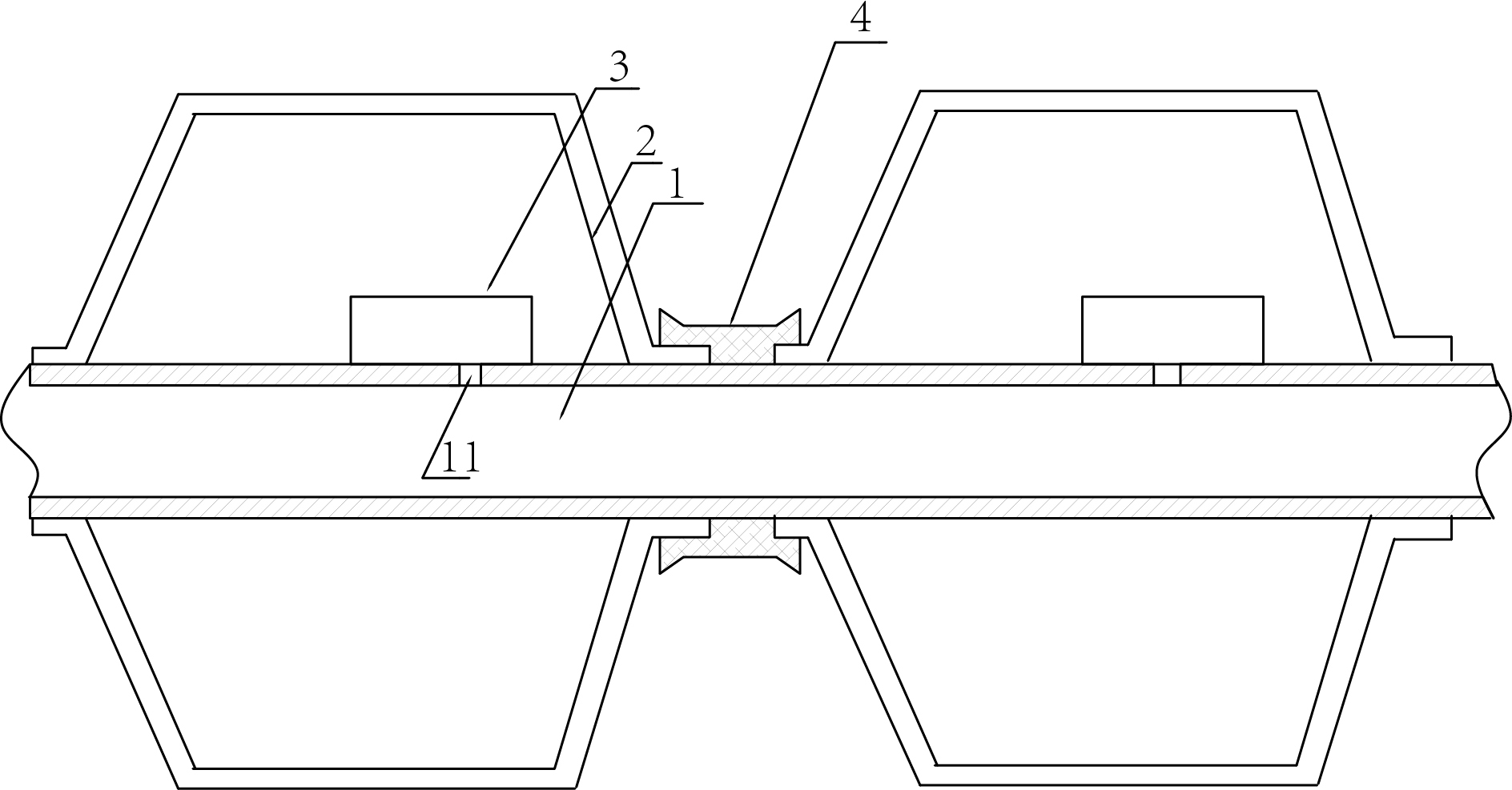

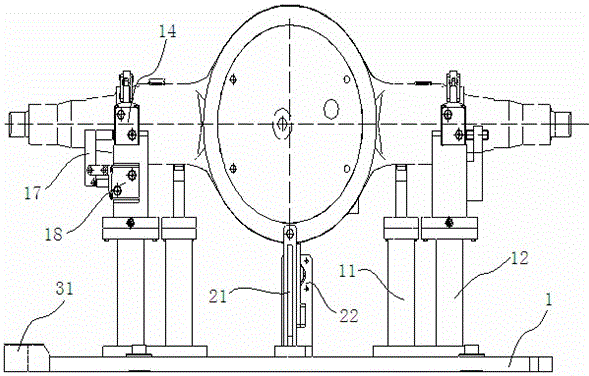

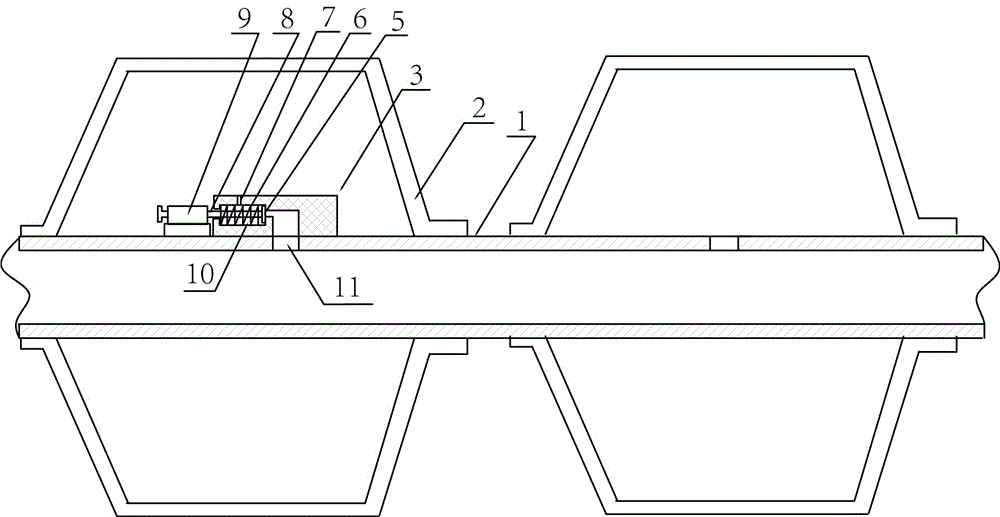

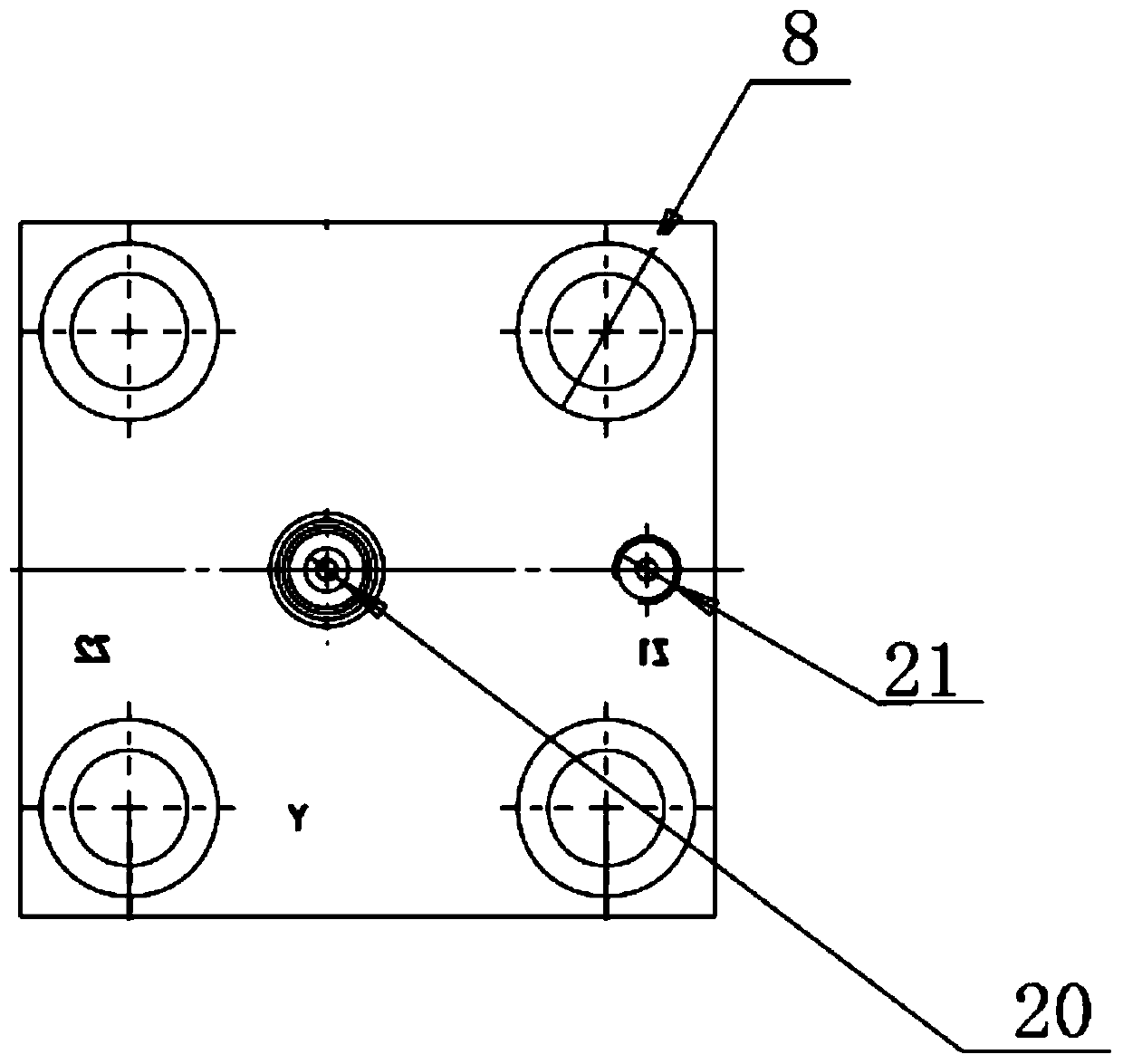

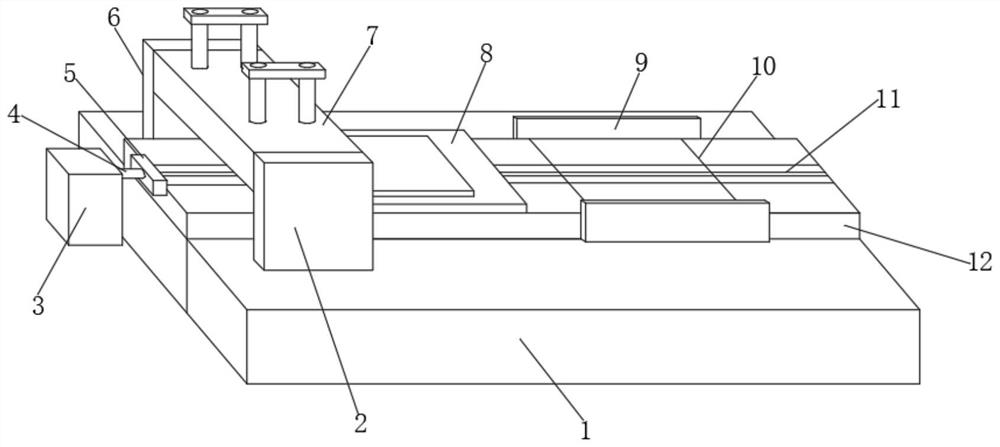

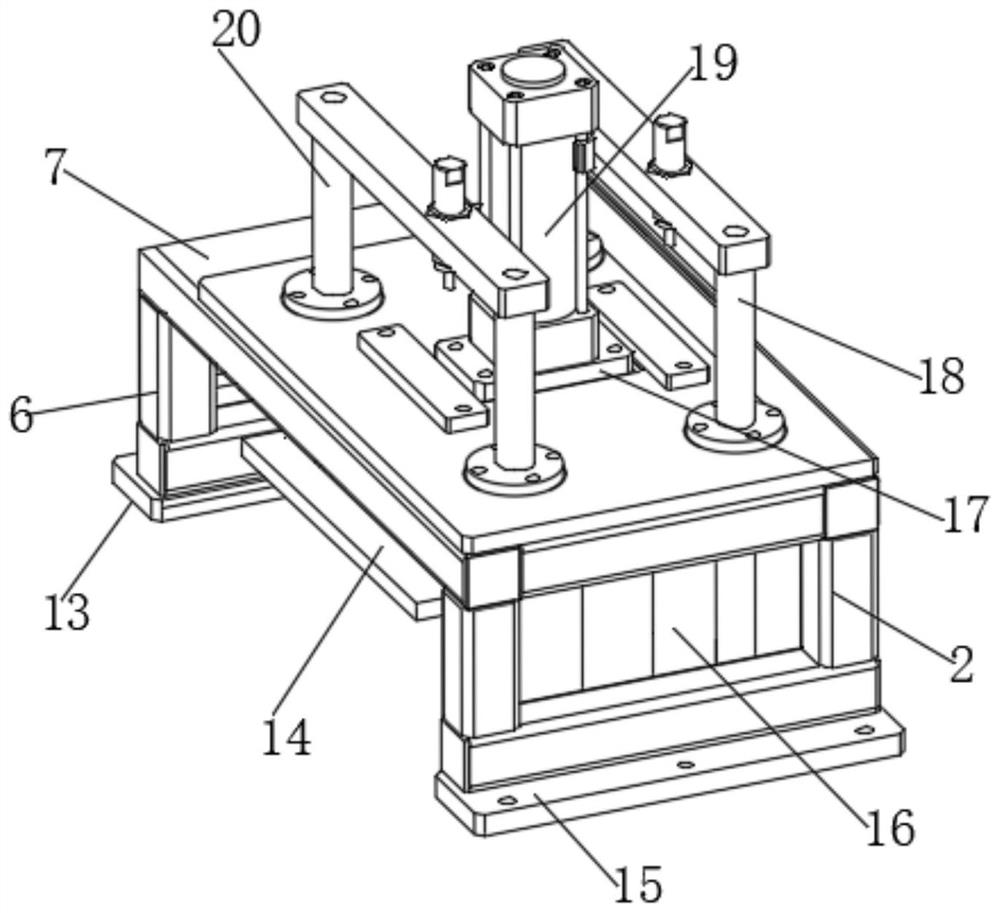

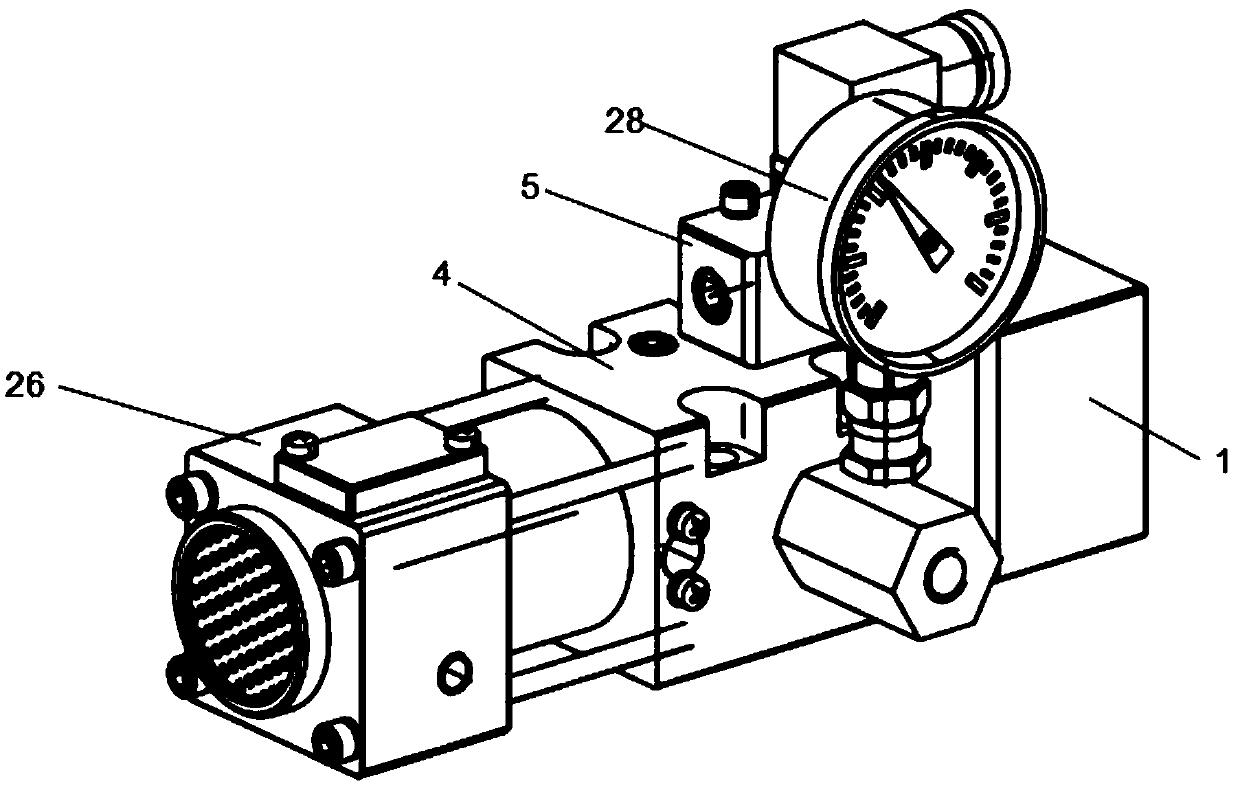

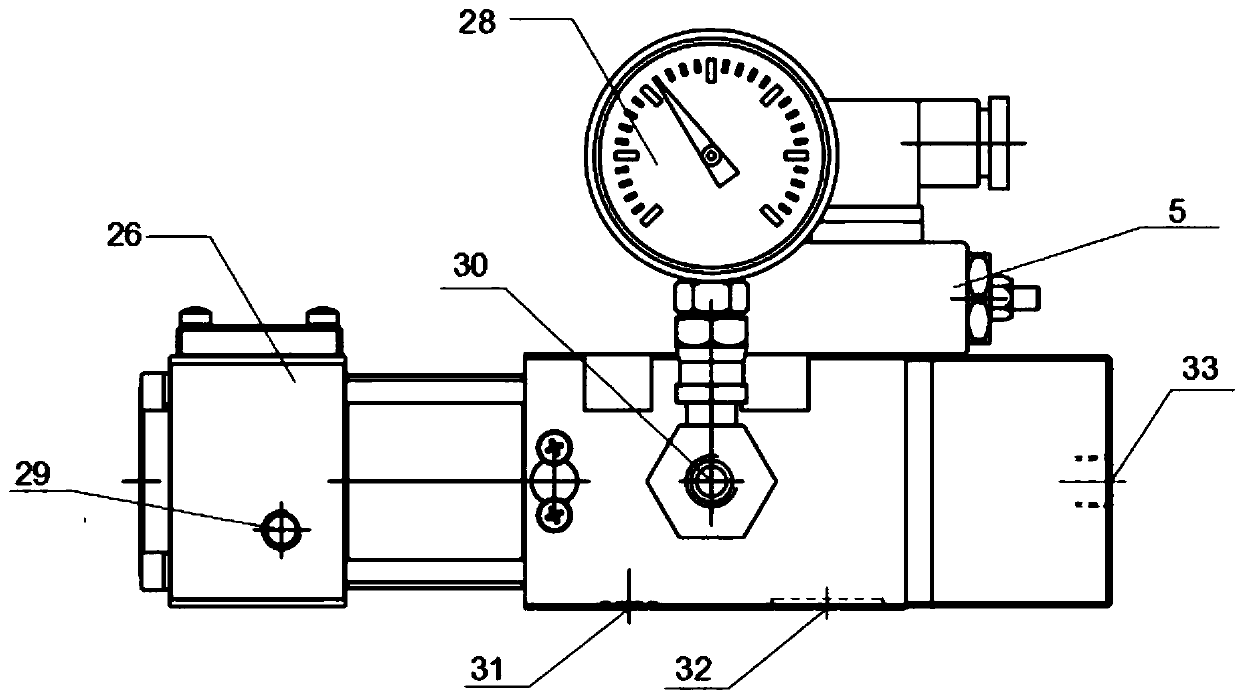

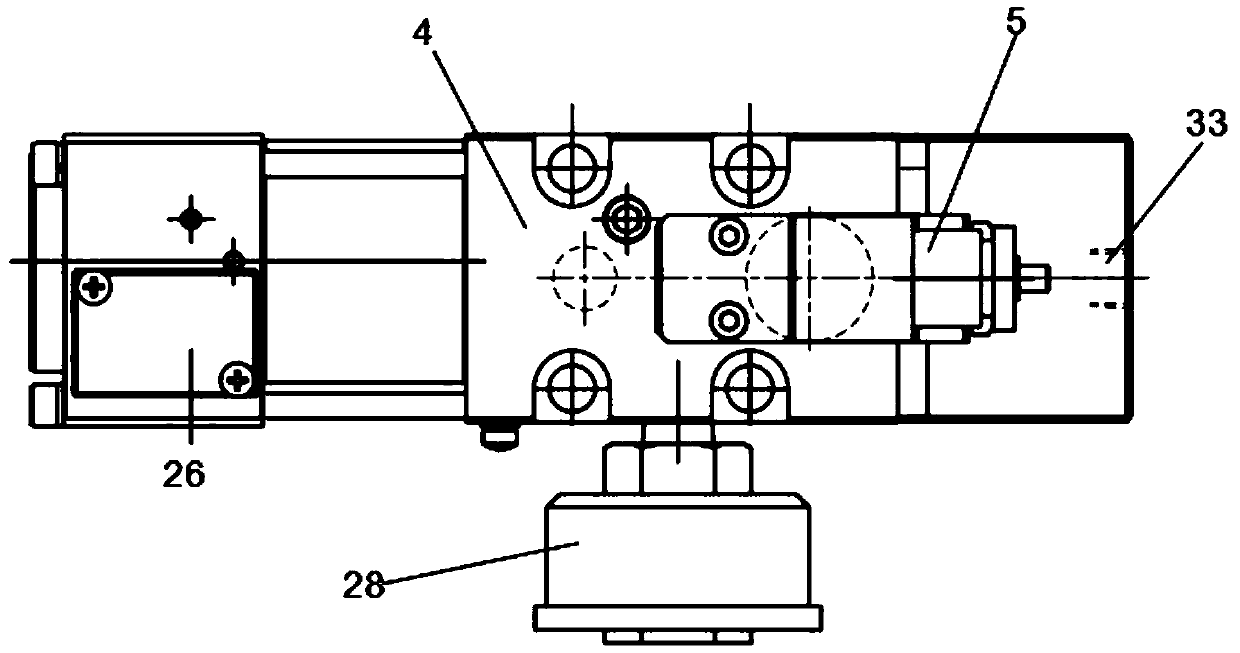

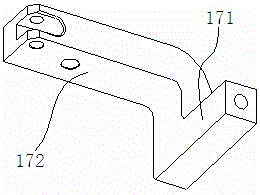

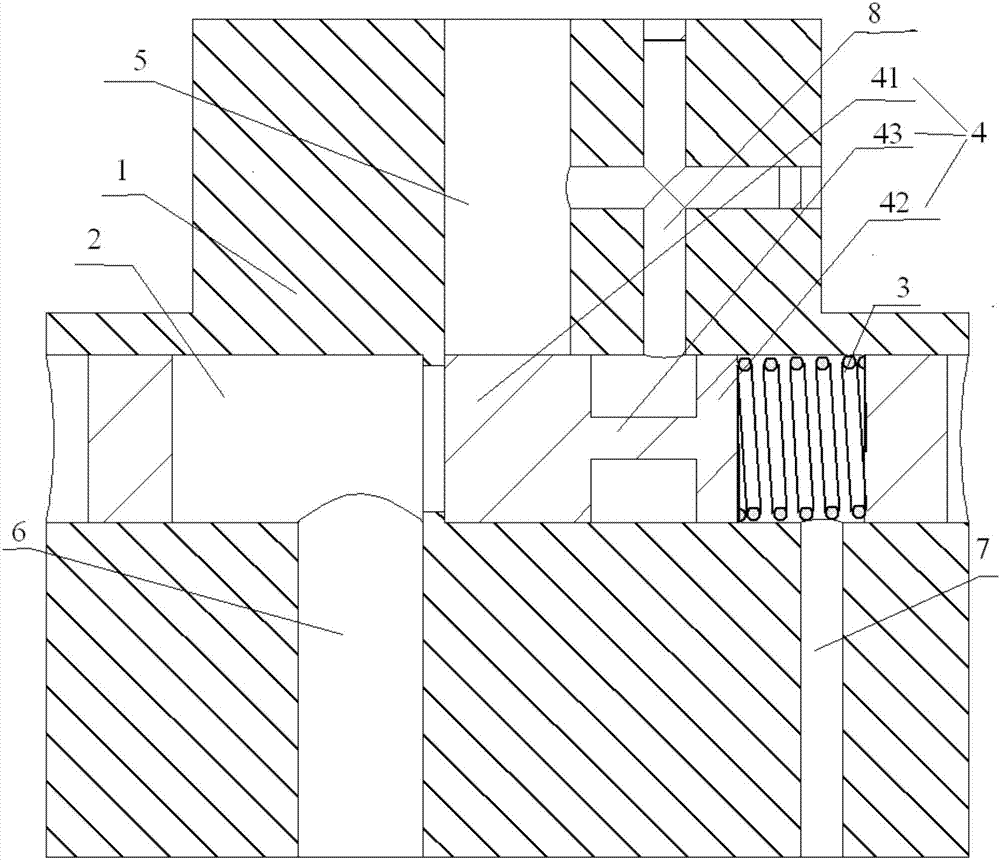

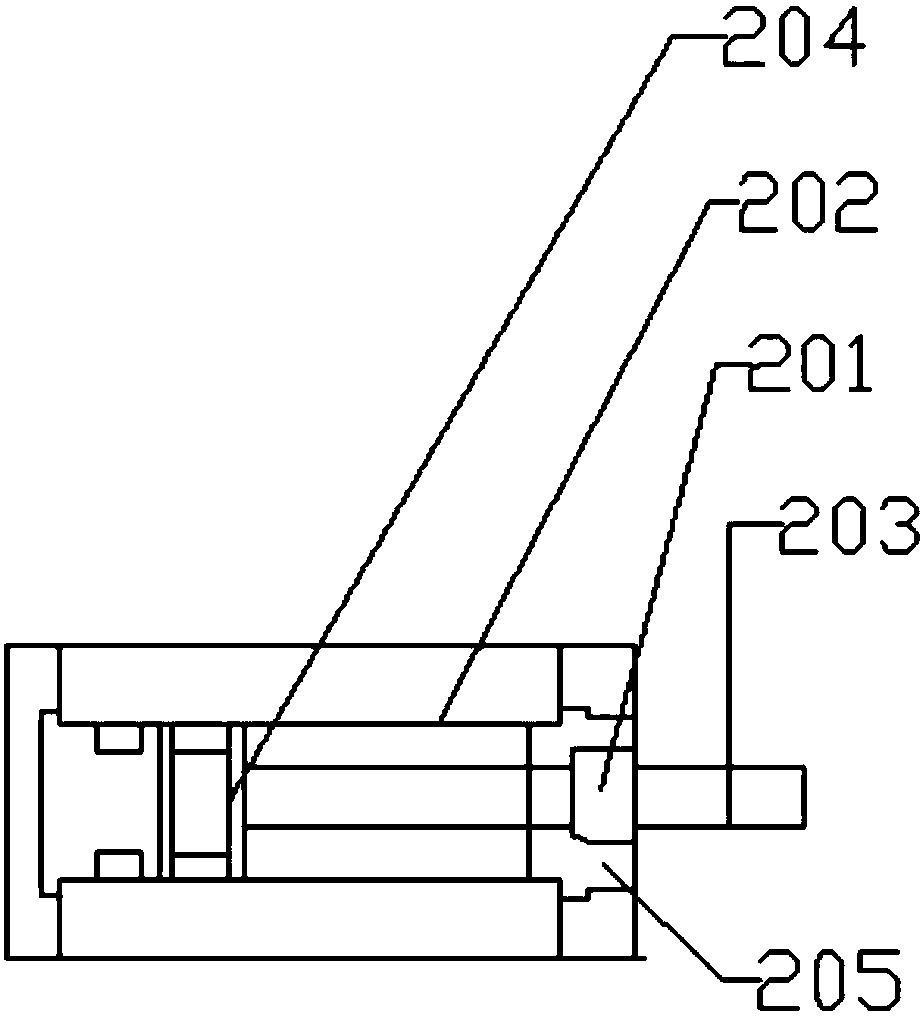

Pressure maintaining fixture of axle housing automation line

The invention discloses a pressure maintaining fixture of an axle housing automation line. The pressure maintaining fixture comprises a fixture body and a clamping device, wherein the fixture body is in a plate structure, and is provided with a hydraulic oil runner inside; the clamping device comprises two V-shaped clamping bases arranged above the fixture body, and a positioning clamper arranged above the fixture body and positioned between the two V-shaped clamping bases; each V-shaped clamping base comprises a static clamping column and a movable clamping column; a first thin oil pressure cylinder and a tension arm driven by the first thin oil pressure cylinder are vertically arranged at the upper end of each movable clamping column; clamping rods for clamping the two ends of an axle housing and second thin oil pressure cylinders for driving the clamping rods are arranged at the outer side of each movable clamping column; and the positioning clampers comprise static positioning blocks and movable positioning blocks. The pressure maintaining fixture of the axle housing automation line can guarantee the clamping force of the fixture to reach the positioning requirement so as to reliably fix the axle housing.

Owner:ANHUI HELI CO LTD

Production method of high-purity dense arsenopyrite electrode

ActiveCN110256079AEliminate interfaceSolve technical problems of galvanic corrosion resultsPyrophylliteBoron nitride

The invention discloses a production method of a high-purity dense arsenopyrite electrode. The production method of the high-purity dense arsenopyrite electrode comprises the steps of selecting arsenopyrite ore particles; cleaning the selected arsenopyrite ore particles, and then drying the arsenopyrite ore particles for use; grinding the dried arsenopyrite ore into powder in meshes of 200 or above, weighing 0.8-1.0 g of the powdery arsenopyrite ore, and after the powdery arsenopyrite ore is compressed into arsenopyrite cylinders in a powder compressing machine, wrapping the arsenopyrite cylinders with silver foil; pressing the arsenopyrite cylinders wrapped with the silver foil into boron nitride to produce boron nitride cylinders which contain the arsenopyrite cylinders wrapped with the silver foil; placing the boron nitride cylinders which contain the arsenopyrite cylinders wrapped with the silver foil into a pyrophyllite lump high-pressure assembly; conducting sintering at high temperature and high pressure in a large-cavity press machine; and stripping off the surface silver foil of a sample subjected to sintering to produce the arsenopyrite electrode. The technical problems that high-temperature and high-pressure electrochemistry experiment research on arsenopyrite requires good pressure maintaining performance of arsenopyrite ore, however, natural arsenopyrite ore hardly meets the condition, and the like are solved.

Owner:INST OF GEOCHEM CHINESE ACADEMY OF SCI

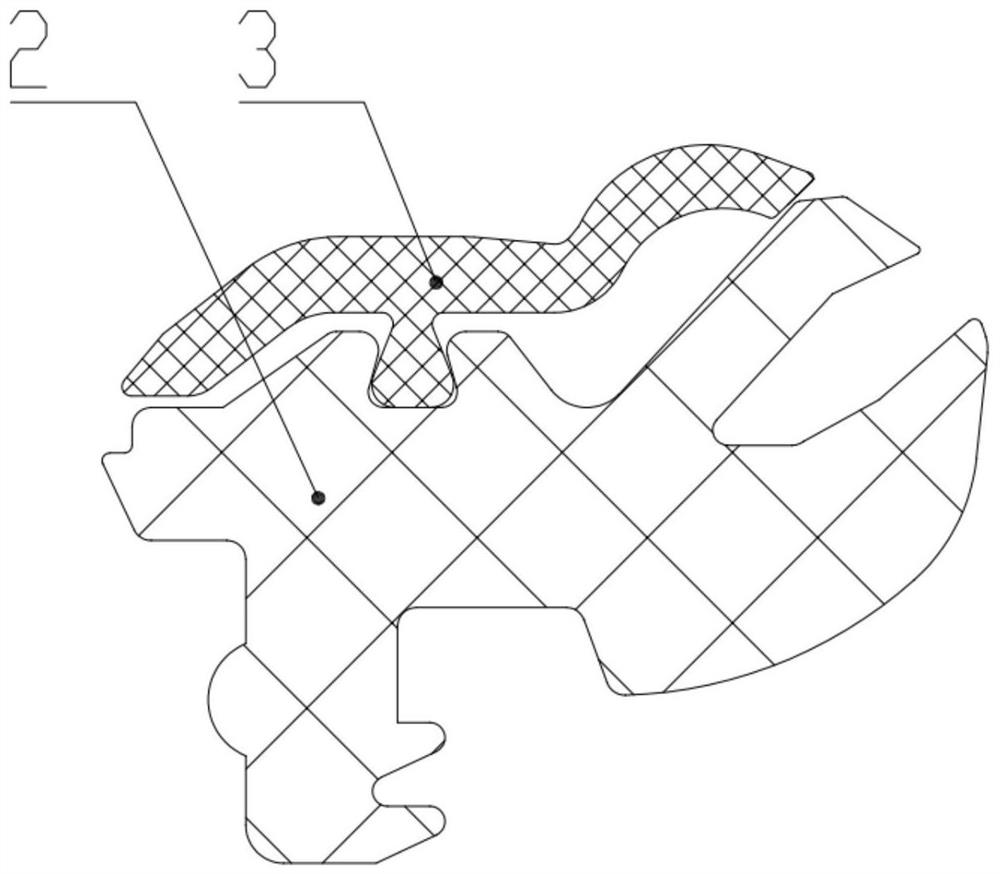

Rubber sealing ring for bearing

PendingCN114542605APrevent leakageEasy to installBearing componentsRenewable energy source integrationEngineeringMechanical engineering

The rubber sealing ring comprises a sealing ring body, a dovetail groove is formed in the upper end of the sealing ring body, a mounting part is arranged at the lower end of the sealing ring body, a triangular fulcrum is arranged at the left end of the sealing ring body, a first sealing limb and a second sealing limb are arranged at the right end of the sealing ring body, and a gap facilitating expansion deformation is reserved between the first sealing limb and the second sealing limb. The front end of the first sealing limb is provided with a first inclined surface and a second inclined surface which intersect to form a sealing lip extending forwards, the sealing lip is in contact fit with a first sealing surface of an inner ring or an outer ring of the bearing, the second sealing limb is matched with a radial groove of the bearing, the upper end surface of the second sealing limb is of a multi-section inclined surface structure, and the lower end surface of the second sealing limb is of an inclined surface and arc structure; the front end of the second sealing limb serves as a sealing lip to be in contact fit with the second sealing face in the radial groove, a protruding blocking shoulder is arranged on the lower side of the second sealing limb, and the blocking shoulder is in contact fit with the blocking shoulder of the fixing groove. The device can effectively prevent leakage of lubricating grease, and has the advantages of good pressure maintaining performance, small rotating torque, convenience in installation and use and the like.

Owner:NANJING ORIENTLEADER TECH CO LTD +1

Gas-liquid balance device of vertical ram milling head

ActiveCN103302548BAvoid mechanical accidentsGood pressure retentionMechanical apparatusMaintainance and safety accessoriesControl valvesSafety valve

Owner:JIER MACHINE TOOL GROUP

Rotary valve stem and control valve

ActiveCN105298963BSimplify processing difficultyReduce processing difficultyPlug valvesServomotor componentsRotary valveEngineering

The invention relates to a rotary valve type valve rod and a control valve in order to overcome the defects of difficult machining and high fabrication cost of existing rotary valve type valve rods. The rotary valve type valve rod comprises a plurality of valve rod sections; valve rod oil channels are designed in the valve rod sections; the adjacent valve rod sections are sequentially and fixedly connected in the axial direction; the positions, on the axial end faces of the valve rod sections, of the valve rod oil channels are communicated with the outside or with the valve rod oil channels in the adjacent valve rod sections; some valve rod sections are provided with spherical surface joints which are provided with annular spherical surfaces surrounding the valve rod sections; each annular spherical surface is provided with a valve rod oil opening which is communicated with the corresponding valve rod oil channel. The valve rod is mainly composed of the multiple valve rod sections, the machining difficulty of the valve rod sections is low, and molding for forming the valve rod oil channels is simple. Meanwhile, the structures of part of the multiple valve rod sections forming the valve rod can be made to be identical, the interchangeability can be greatly improved, and the machining difficulty can be greatly reduced.

Owner:LIUZHOU LIUGONG HYDRAULIC COMPONENTS +1

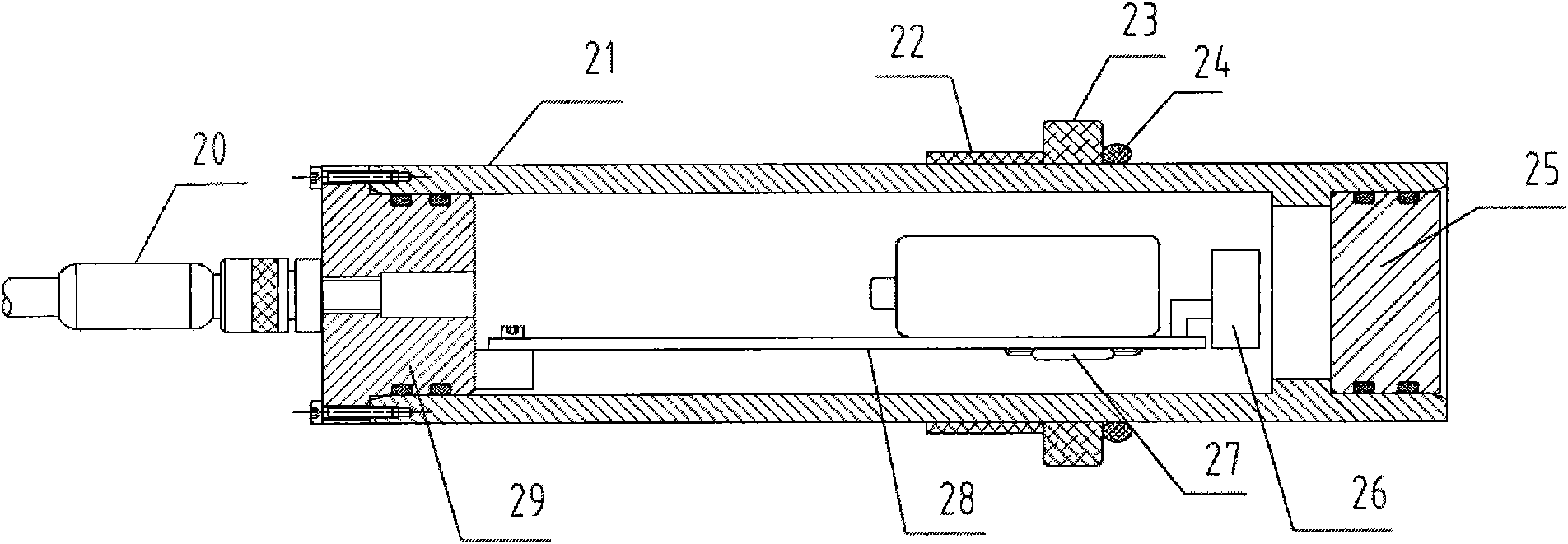

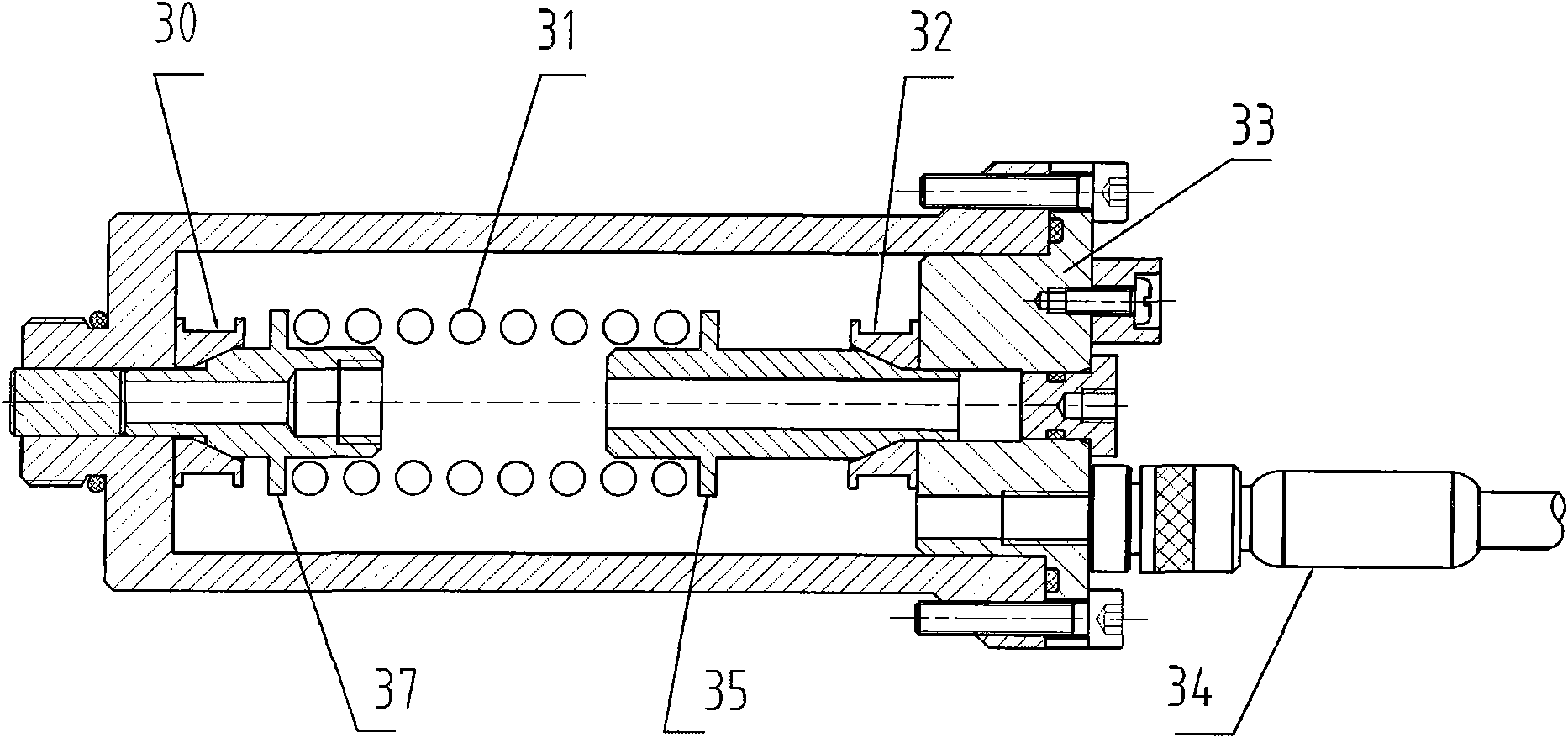

Hydraulic pressure-triggering deep sea hot liquid air-tight sampling instrument

The invention discloses a hydraulic pressure triggered deep sea thermal water air tight sampler comprising a sampling valve, a sampling cavity, an energy storage cavity, a circuit cavity, and a hydraulic pressure trigger mechanism in coaxial connection with the sampling valve. The sampler provided by the invention is characterized in that the sampling valve is turned on and off through hydraulic driving; the trigger mechanism has a simple structure, and the reliability of action is high; and the thrust necessary for turning on the sampling valve can be greatly reduced because the hydraulic pressure trigger mechanism is capable of amplifying force. By utilizing the compressed nitrogen in the energy storage cavity to compensate for pressure, the sampler has excellent pressure maintaining performance. The sampler is integrated with a temperature measurement system, so that the real-time temperature of the thermal water can be obtained during the process of sampling. Furthermore, the sampler with a compact overall structure and a small overall size is suitable for the operation of a manipulator of a deep submergence vehicle.

Owner:ZHEJIANG UNIV

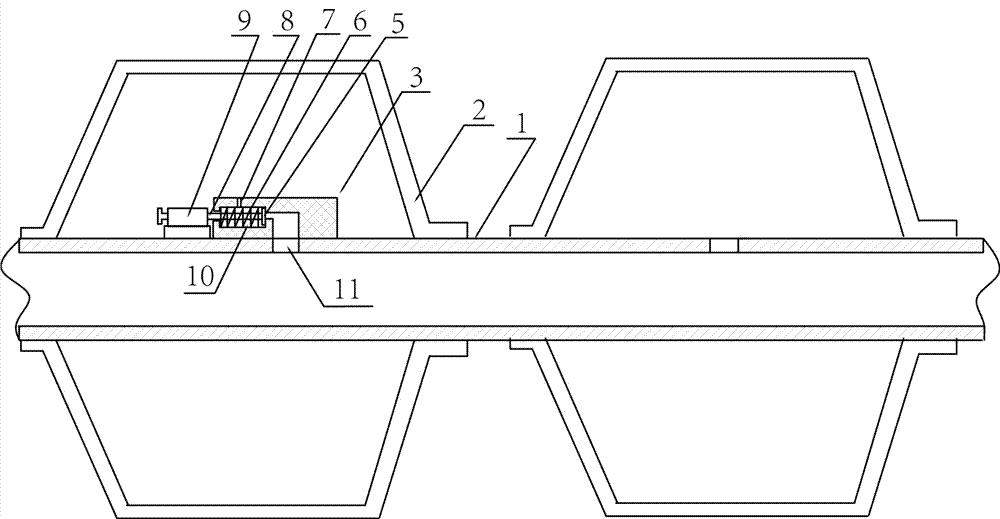

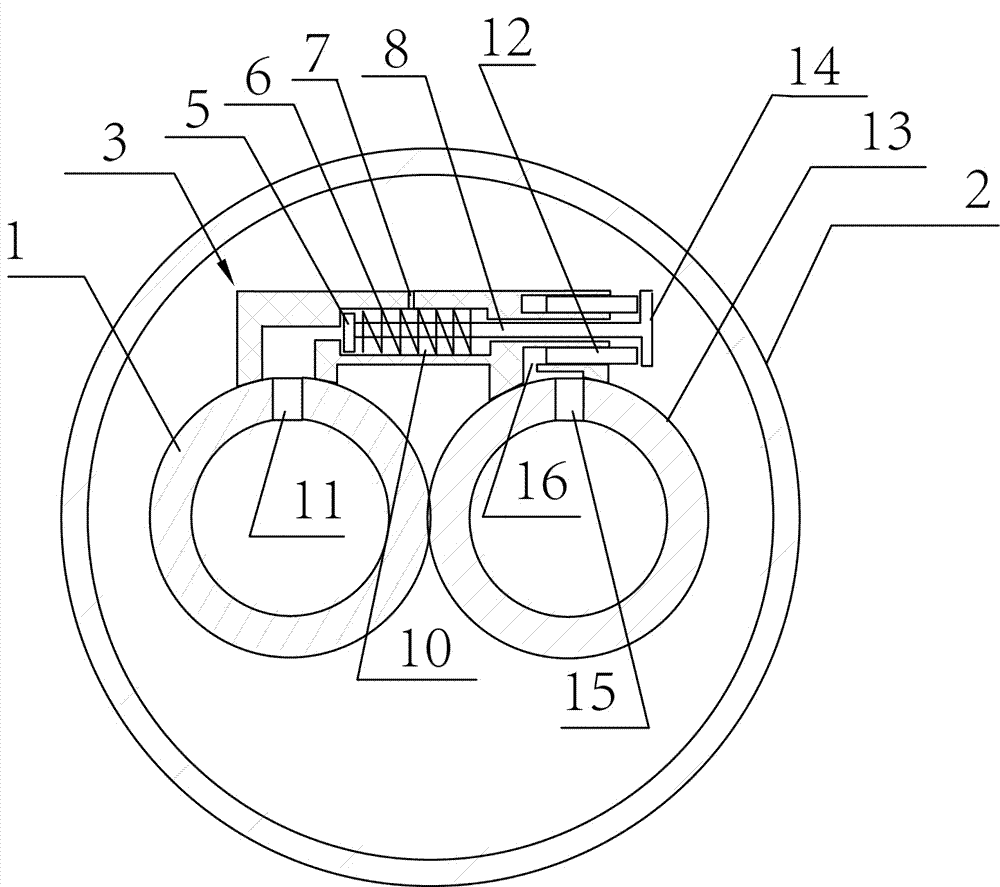

Concatenation airbag with inflating-deflating cavity

ActiveCN103661835AEasy to useGood pressure retentionWaterborne vesselsSpecial purpose vesselsAirbagEngineering

The invention relates to a concatenation airbag with an inflating-deflating cavity. The concatenation airbag comprises an inflating-deflating main pipe (1) and a plurality of airbag units (2) which are sequentially arranged along the inflating-deflating main pipe (1); each airbag unit (2) is provided with an inflating-deflating control device (3), and each inflating-deflating control device (3) is respectively connected with an inflating-deflating pore (11) on the inflating-deflating main pipe (1). The inflation and deflation are completed through one main pipe. The concatenation airbag with the inflating-deflating cavity is simpler in pipeline layout and can be lengthened in a concatenation manner according to the requirement. When one airbag unit leaks the air, the other airbag units are not influenced, and the normal application of the entire concatenation airbag with the inflating-deflating cavity can be guaranteed.

Owner:徐州博创建设发展集团有限公司

Tandem airbags with inflatable and deflated chambers

ActiveCN103661835BEasy to useGood pressure retentionWaterborne vesselsSpecial purpose vesselsEngineeringAirbag deployment

The invention relates to a concatenation airbag with an inflating-deflating cavity. The concatenation airbag comprises an inflating-deflating main pipe (1) and a plurality of airbag units (2) which are sequentially arranged along the inflating-deflating main pipe (1); each airbag unit (2) is provided with an inflating-deflating control device (3), and each inflating-deflating control device (3) is respectively connected with an inflating-deflating pore (11) on the inflating-deflating main pipe (1). The inflation and deflation are completed through one main pipe. The concatenation airbag with the inflating-deflating cavity is simpler in pipeline layout and can be lengthened in a concatenation manner according to the requirement. When one airbag unit leaks the air, the other airbag units are not influenced, and the normal application of the entire concatenation airbag with the inflating-deflating cavity can be guaranteed.

Owner:徐州博创建设发展集团有限公司

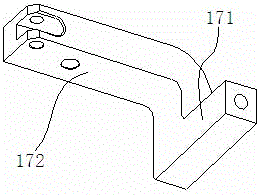

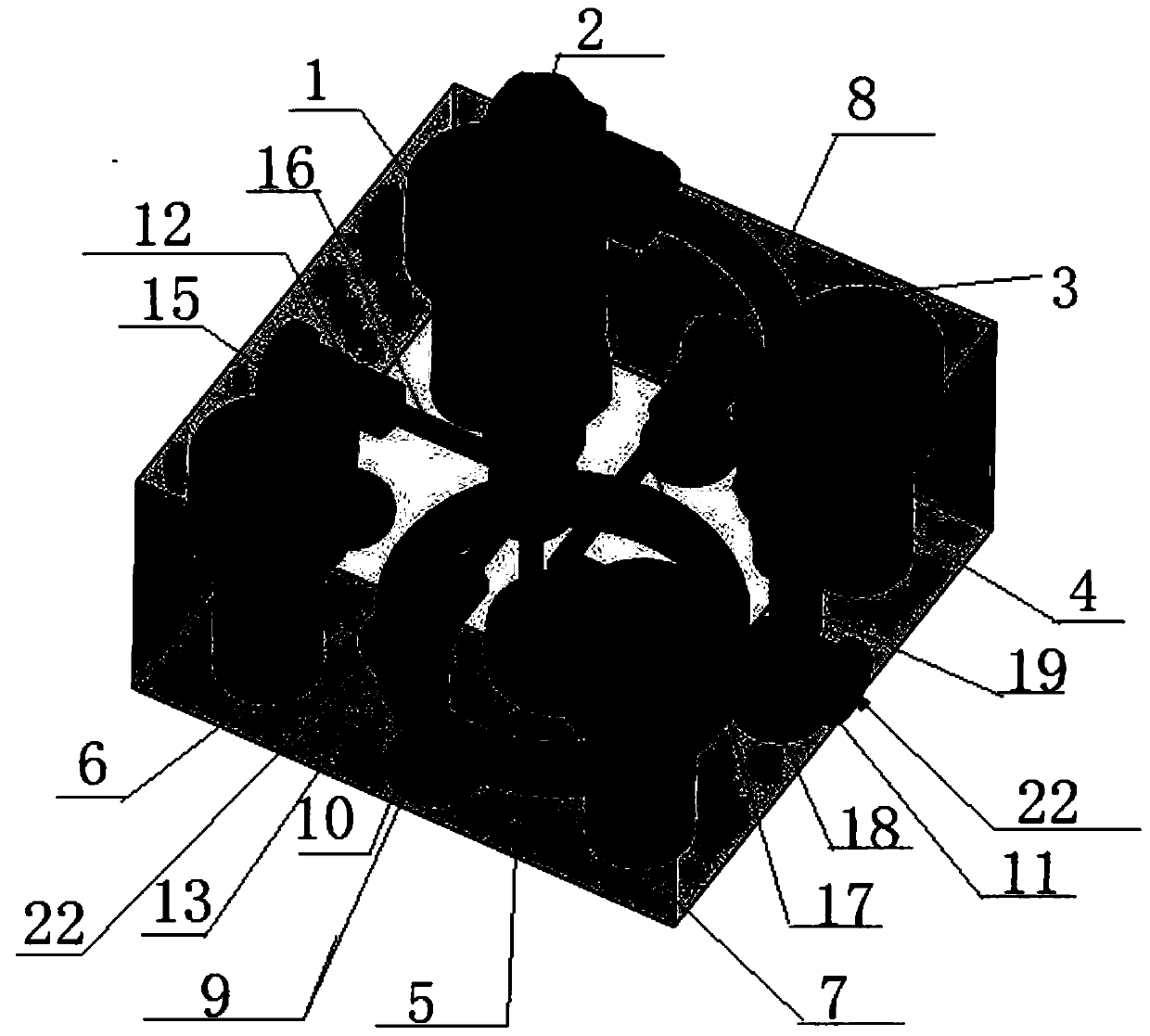

Cartridge valve cover plate device

PendingCN111120447AReduce damage rateReduce labor intensityServomotor componentsValve seatPetroleum engineering

The invention provides a cartridge valve cover plate device. The cartridge valve cover plate device comprises a cover plate body, a threaded cartridge type hydraulic reversing valve, an external control oil way and an internal control oil way; the cover plate body is provided with the threaded cartridge type hydraulic reversing valve, and the internal control oil way is arranged in the cover platebody; the external control oil way comprises an X pilot control oil way; and the internal control oil way comprises a first hole channel, a Z1 pilot control oil way, a Z2 valve element locking oil way and a Y oil drainage opening oil way. When pilot control oil is fed back to a port a of the threaded cartridge type hydraulic reversing valve through the Z1 pilot control oil way through a port X ofa bottom plate of the valve body, a valve element of the threaded cartridge type hydraulic reversing valve is located at the left position, at the moment, a port I communicates with a port III, and aport AB of a main oil way is communicated; when pilot control oil is not given, the threaded cartridge type hydraulic reversing valve returns to the original position, the main valve element of the main oil way is pressed on the valve seat to cut off an opening AB of the main oil way, the pressure maintaining effect is achieved, the damage rate of the hydraulic control one-way valve is effectively reduced, and the cartridge valve cover plate device has the advantages of being resistant to impact, small in leakage amount, capable of effectively maintaining pressure and long in service life.

Owner:JIANGSU YONGGANG GROUP CO LTD

Double faced adhesive tape pressure maintaining work station for adhesive tape pasting and film tearing production

The double-faced adhesive tape pressure maintaining work station comprises an adhesive tape pasting base, a carrier assembly line is installed at the upper end of the adhesive tape pasting base in a positioned mode, an adhesive tape pasting carrier is arranged at the upper end of the carrier assembly line, a sliding rail is arranged on the inner side of the carrier assembly line, a carrier temporary storage base is installed at the tail end of the carrier assembly line, and the adhesive tape pasting carrier is arranged on the carrier temporary storage base. Baffles are installed at the two ends of the carrier temporary storage base, and a second supporting frame and a first supporting frame are installed at the positions, located on the two sides of the carrier assembly line, of the front end of the rubberizing base correspondingly. The double-faced adhesive tape pressure maintaining work station for adhesive tape pasting and film tearing production is provided with the pressure maintaining base, the elastic protection pressing plate and the adhesive tape pasting positioning mechanism, adhesive tape pasting operation can be conveniently and better carried out, good pressure maintaining performance is achieved, pasting is tighter, the adhesive tape pasting effect is improved, products can be conveniently positioned when adhesive tape pasting operation is carried out, the performance is excellent, and the practicability is high. Meanwhile, the adhesive tape is protected, and the situation of damage is not prone to occurring.

Owner:SUZHOU WANXIANG TECH CO LTD

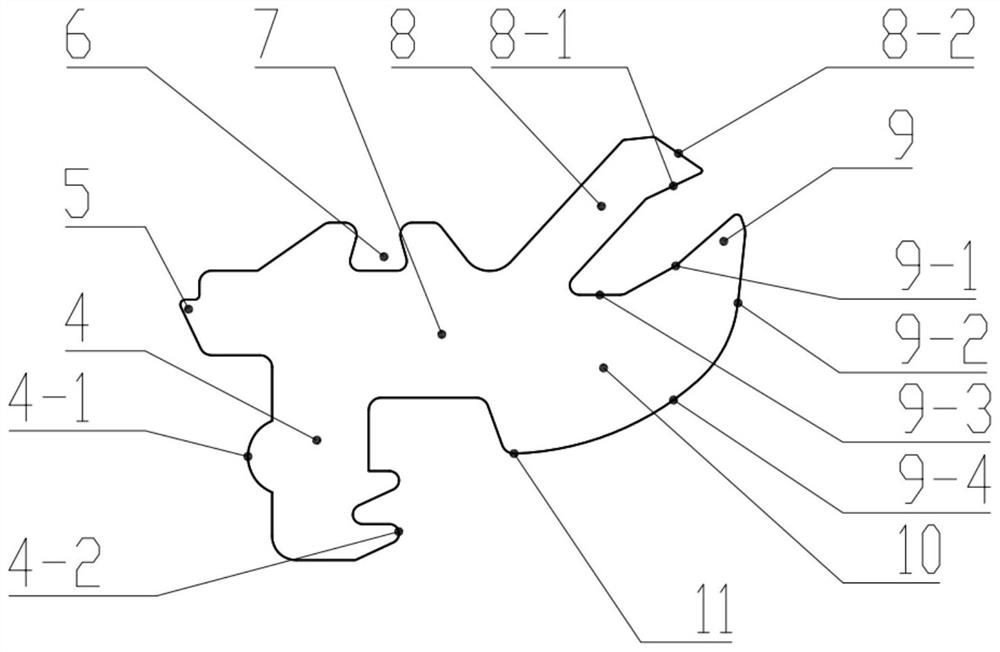

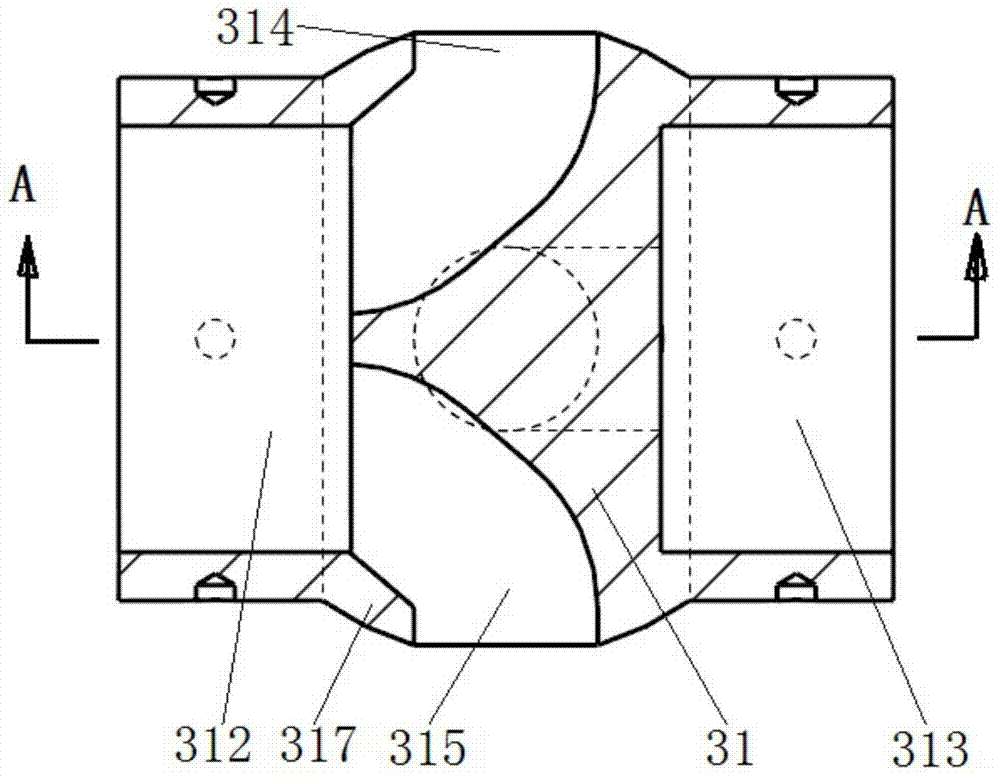

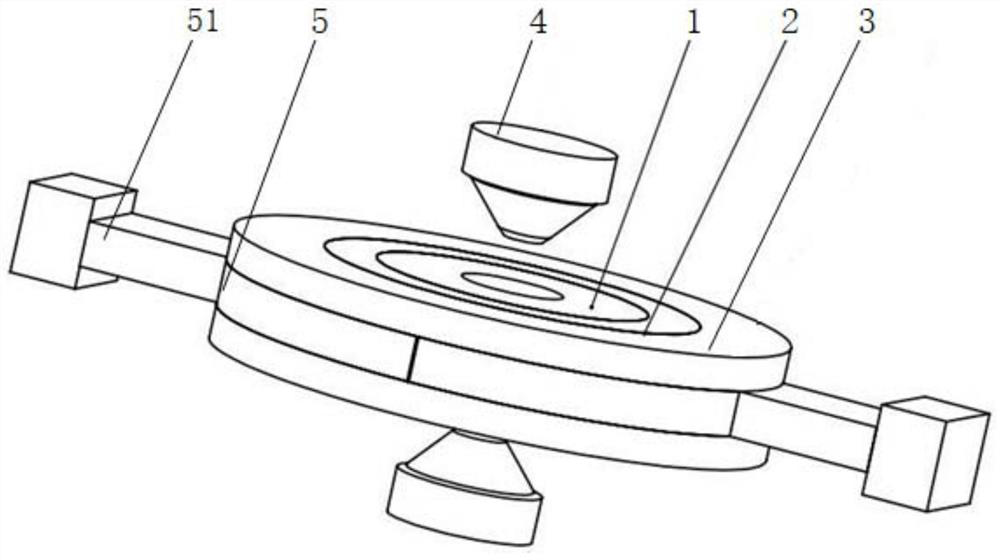

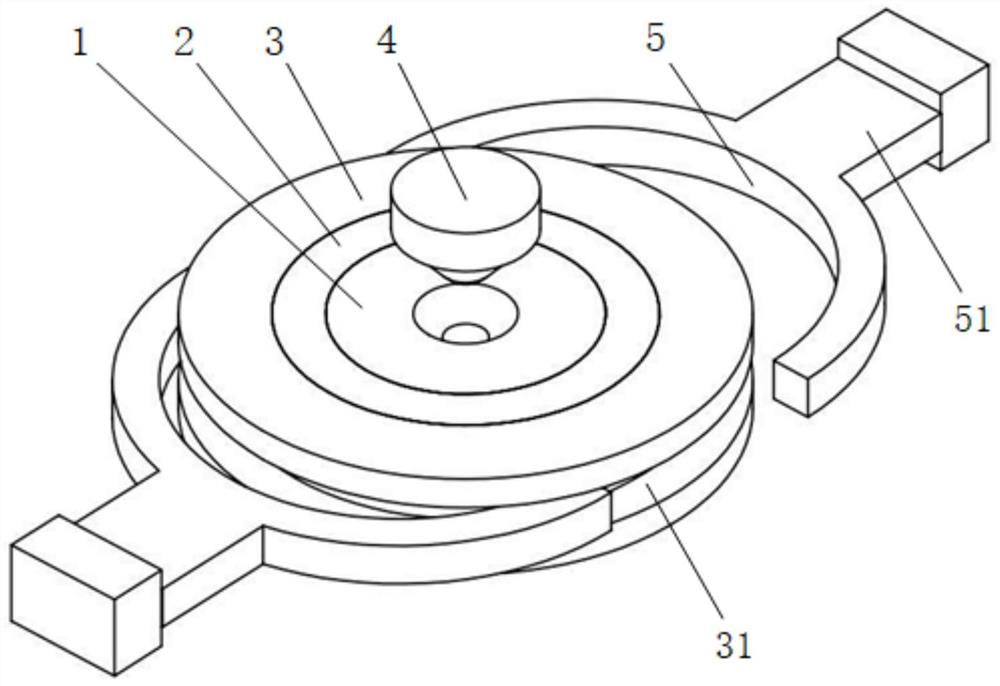

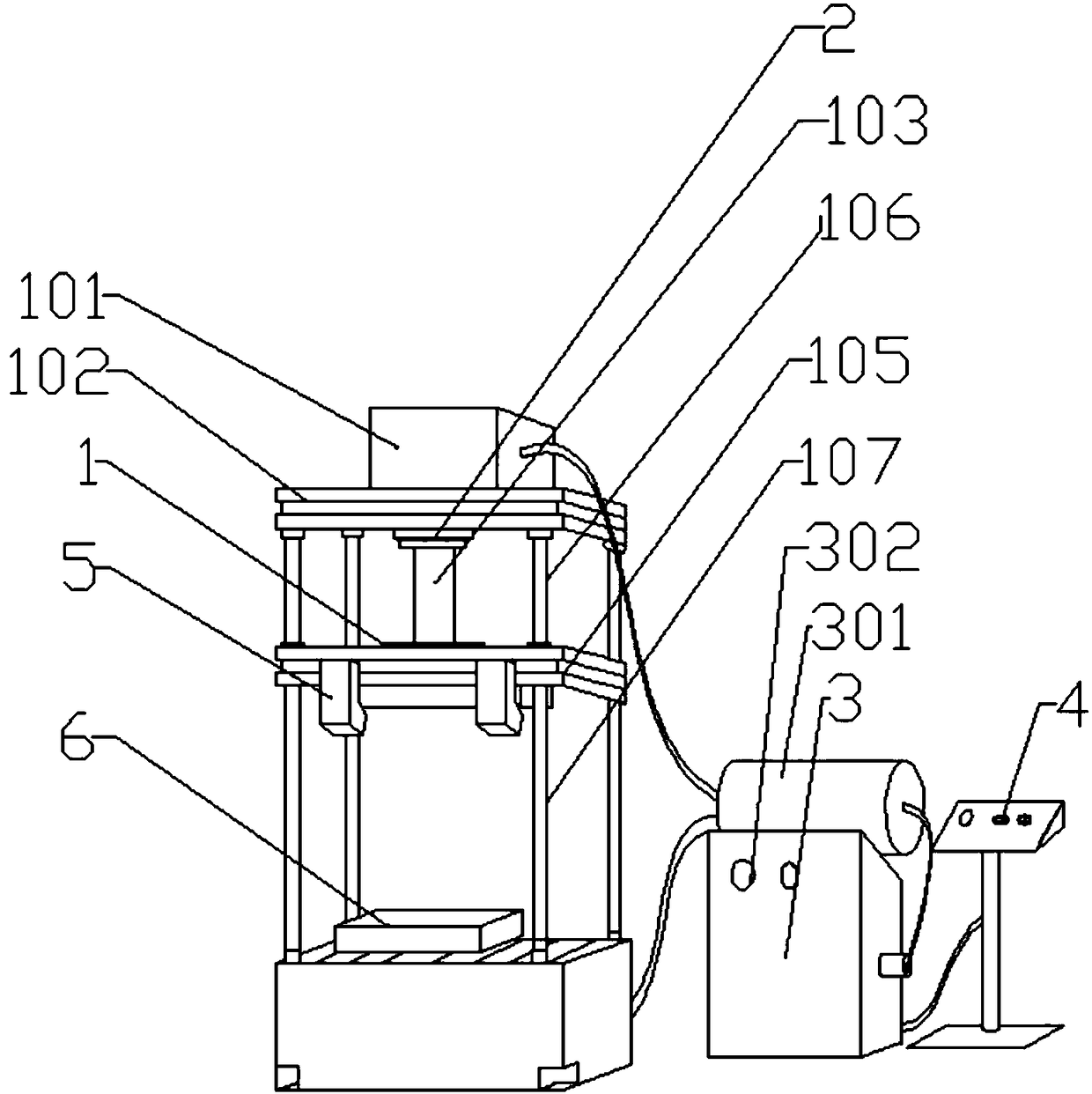

An arc-shaped top hammer type four-sided top ultra-high pressure device

ActiveCN111167377BImprove fatigue strengthGood pressure retentionUltra-high pressure processesInterference fitUltra high pressure

An arc-shaped top hammer type four-sided top ultra-high pressure device, the device includes a cylinder with a cylindrical structure, a support ring installed outside the pressure cylinder through interference fit, and a support ring installed outside the support ring through interference fit. For the centering support ring, the upper and lower ends of the cylinder are respectively provided with mutually symmetrical top hammers in the middle, and both sides of the centering support ring are respectively provided with radial and mutually symmetrical arc-shaped top hammers. The present invention uses four top hammers on the upper, lower and left and right sides to pressurize the pressure cylinder, and the pressure force is closer to the "hydrostatic pressure", so that the pressure cylinder can withstand greater pressure and has better pressure maintaining performance. The heat preservation performance of the top pressure cylinder on both sides is maintained, and the side is pressurized by an arc-shaped top hammer, so there will be no prestress relaxation and creep, so that the pressure cylinder is always under stable pressure during work, and the fatigue strength is high. It is not easy to be damaged, and the stability of pressurization is higher, and it has a very ideal technical effect.

Owner:YANSHAN UNIV

High pressure model-locked loop of double movable plate direct press injection machine

The invention relates to a high pressure die-locking circuit of a dual-motion plate direct pressure injection machine, comprising an oil pump which is driven by an electric motor, an electromagnetic reversing valve, an electromagnetic switch valve, overflow valves, a hydraulic control check valve and a high pressure die-locking oil cylinder; the electric motor drives the oil pump; the oil outlet of the oil pump is connected with the electromagnetic reversing valve; one working oil nozzle of the electromagnetic reversing valve is connected with the high pressure chamber of the high pressure die-locking oil cylinder through the hydraulic control check valve; another working oil nozzle of the electromagnetic reversing valve is connected with the recovery chamber of the high pressure die-locking oil cylinder; the oil outlet of the oil pump and the recovery chamber of the high pressure die-locking oil cylinder are both provided with the overflow valves; the non-rod chamber of the high pressure die-locking oil cylinder is connected with an oil tank through the electromagnetic switch valve. The proposal sufficiently considers the working characteristics of the dual-motion direct pressinginjection machine and optimizes and simplifies the high pressure die-locking control oil path, and the invention is the high pressure die-locking circuit of the dual-motion direct pressing injection machine with more reasonable structure.

Owner:广东佳明机器有限公司

Locking pump for fast punch sliding-block oil cylinder locking

PendingCN109555737ASmall sizeIngenious designFluid-pressure actuator testingServomotor componentsPistonOil pressure

The invention provides a locking pump for fast punch sliding-block oil cylinder locking. The locking pump comprises a locking pump shell, a first piston, an unloading one-way valve, an oil returning opening, a cylinder cover, an oil outlet, an oil suction and an air pump, wherein the first piston is arranged on the left end side of the locking pump shell, the unloading one-way valve is installed on the right side of the first piston, the oil returning opening is formed in the bottom of the locking pump shell, and the oil returning opening communicates with the unloading one-way valve; the cylinder cover is installed on the left end side of the locking pump shell and wraps the first piston, an unloading air supply opening is formed in the middle of the cylinder cover and communicates with the first piston, the oil outlet is formed in the middle of the front side of the locking pump shell, and a discharge one-way valve is arranged at the oil outlet; and the oil suction is formed in the bottom of the locking pump shell, a suction one-way valve is installed at the oil suction, and the air pump is installed on the right side of the locking pump shell. According to the locking pump for fast punch sliding-block oil cylinder locking, it can be guaranteed that the locking pump cannot be influenced by the change of oil pressure in a sliding block oil cylinder, and the stability of the oil cylinder pressure can be better maintained.

Owner:HUAMAO MACHINERY ZHAOQING

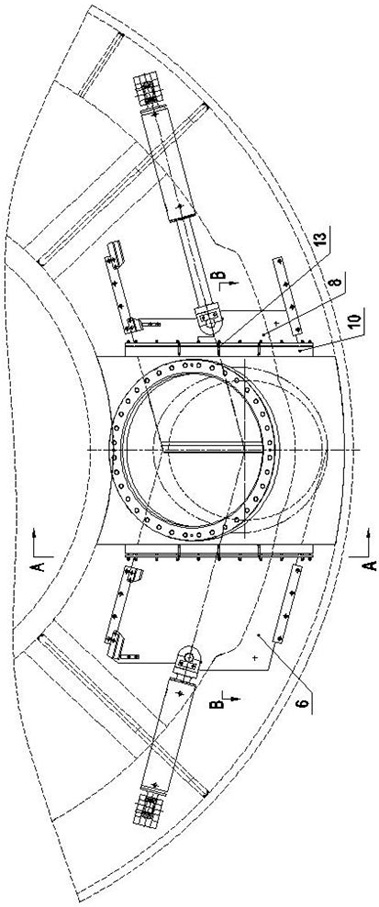

A double-gate structure of the front gate gate of the bulkhead of the earth pressure balance shield screw conveyor

The invention discloses a double-gate structure of the front gate of the bulkhead of an earth pressure balance shield screw conveyor, which comprises a left gate, a right gate, an oil nozzle and a driver, and the left gate and the right gate are relatively movably arranged behind the front bulkhead part, and the left gate and the right gate cooperate with each other and form a sealed cavity; the driver includes a left driver and a right driver, and the left driver and the right driver are symmetrically arranged on the outside of the left gate and the right gate respectively, and the movable end of the left driver is connected to the left The gate is fixedly connected, and the movable end of the right driver is fixedly connected with the right gate; both the left gate and the right gate are provided with oil nozzles, and the oil nozzles communicate with the sealing chamber. The present invention realizes the complete sealing and pressure maintaining of the soil chamber of the shield machine by arranging a double gate structure on the front bulkhead of the screw conveyor and injecting grease into the sealing chamber for sealing.

Owner:CHINA RAILWAY ENGINEERING EQUIPMENT GROUP CO LTD

A pressure-holding fixture for automatic line of axle housing

The invention discloses a pressure maintaining fixture of an axle housing automation line. The pressure maintaining fixture comprises a fixture body and a clamping device, wherein the fixture body is in a plate structure, and is provided with a hydraulic oil runner inside; the clamping device comprises two V-shaped clamping bases arranged above the fixture body, and a positioning clamper arranged above the fixture body and positioned between the two V-shaped clamping bases; each V-shaped clamping base comprises a static clamping column and a movable clamping column; a first thin oil pressure cylinder and a tension arm driven by the first thin oil pressure cylinder are vertically arranged at the upper end of each movable clamping column; clamping rods for clamping the two ends of an axle housing and second thin oil pressure cylinders for driving the clamping rods are arranged at the outer side of each movable clamping column; and the positioning clampers comprise static positioning blocks and movable positioning blocks. The pressure maintaining fixture of the axle housing automation line can guarantee the clamping force of the fixture to reach the positioning requirement so as to reliably fix the axle housing.

Owner:ANHUI HELI CO LTD

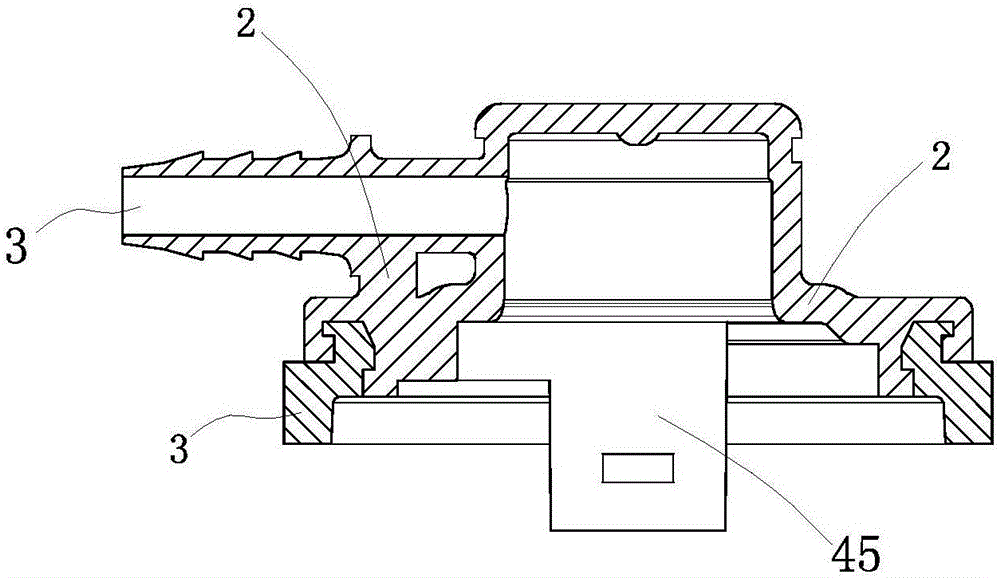

Car pilot-operated type fuel pump pressure regulator

ActiveCN107255057ASimple structureReasonable designInternal combustion piston enginesLiquid fuel feedersLeft valvePressure regulator

The invention discloses a car pilot-operated type fuel pump pressure valve. A fuel channel with the axis extending in the left-right direction is formed in the middle of a valve body, and the two ends of the fuel channel are sealed. The lower end of a fuel feeding channel communicates with the fuel channel, the upper ends of a first fuel discharging channel and a second fuel discharging channel communicate with the fuel channel, and the fuel feeding channel is located between the first fuel discharging channel and the second fuel discharging channel. A side channel is formed in the middle of the fuel feeding channel, and the lower end of the side channel communicates with the fuel channel and located between the fuel feeding channel and the second fuel discharging channel. A valve core is mounted in the fuel channel, the right end of the valve core is connected with a pressure adjusting spring, and the pressure adjusting spring tightly abuts against the right end of the fuel channel. The valve core comprises a left valve core body and a right valve core body, a gap is formed between the left valve core body and the right valve core body, and the left valve core body and the right valve core body are connected through a connecting part. The left valve core body is located below the fuel feeding channel, the connecting part is located below the side channel, and the right valve core body is located between the side channel and the second fuel discharging channel. Pressure maintaining is stable, and the pressure characteristic is good.

Owner:CHONGQING WANLI LIANXING IND GROUP

Curved-surface hydraulic device for forming of air conditioner reservoir compressor connection bracket

PendingCN108435854AWell-processedGood pressure holding performanceMetal working apparatusHydraulic pumpHydraulic pressure

The invention discloses a curved-surface hydraulic device for forming of an air conditioner reservoir compressor connection bracket. The curved-surface hydraulic device comprises a hydraulic device main body, a hydraulic cylinder and a hydraulic pump station; the top of the hydraulic device main body is provided with an upper transverse beam, and the upper transverse beam is fixedly connected withthe hydraulic device main body; a piston rod is arranged at the bottom of the upper transverse rod and movably connected with the upper transverse beam, the top end and the bottom end of the piston rod are provided with adjusting nuts correspondingly, and the adjusting nuts are fixedly connected with the piston rod; the middle of the hydraulic device main body is provided with a middle beam, andthe middle beam is fixedly connected with the hydraulic device main body; and the top of the hydraulic device main body is provided with a liquid filling box. When a hydraulic actuating mechanism, thehydraulic cylinder or a hydraulic motor operates in an accelerated mode under the action of loads, a hydraulic system cannot supply oil in time, and using is conducted in order to avoid the vacuum condition; and the curved-surface hydraulic device has the characteristics of being excellent in machining, high in precision, free of leakage and good in pressure maintaining performance, the curved-surface hydraulic device is provided with a slow-action valve core, and thus, the curved-surface hydraulic device is safe and has wide using prospects in the future.

Owner:WUHU ZHUOYUE AIR CONDITIONING PARTS CO LTD

Rotary control valve

The invention relates to a control valve. By means of the control valve, the deficiencies that an existing control valve is large in leakage amount and low in reliability are overcome. The control valve comprises a valve body and a valve rod. The two ends of the valve rod are provided with a positioning mechanism and a rotating mechanism respectively. Valve rod oil channels are formed in the valve rod. The valve rod is provided with spherical sections. Valve rod oil ports communicated with the valve rod oil channels are formed in the spherical sections. Valve port channels which are perpendicular to the valve rod are formed in the valve body. Sleeves are arranged in the valve port channels. One ends of the sleeves make contact with the spherical sections in a line seal mode, and the other ends of the sleeves are provided with springs. The springs provide elastic force for the sleeves. Spring cavities are communicated with valve body oil channels in the valve body. When the valve rod oil ports and the sleeves are opposite, the valve rod oil channels are communicated with the valve body oil channels through the sleeves. According to the rotary-valve-type control valve, when the valve rod is rotated, the valve rod oil channels are communicated with different oil channels in the valve body through the cooperation between the valve rod oil ports and the sleeves, and the trend of oil ways is controlled. The spherical sections are in line-contact connection with the sleeves in a cone sealing mode, good sealing line-contact can be maintained, the control valve cannot be stuck, and the rotary-valve-type control valve has the advantages of being small in leakage amount and high in reliability.

Owner:LIUZHOU LIUGONG HYDRAULIC COMPONENTS +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com