Liquid pressure-maintaining and sampling tube

A sampling cylinder and liquid technology, applied in the direction of sampling devices, etc., can solve the problems that the sampler can no longer be sampled and the disassembly is complicated, and achieve the effect of simple structure, convenient operation and reliable sampling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] The present invention will be further described below in conjunction with the accompanying drawings.

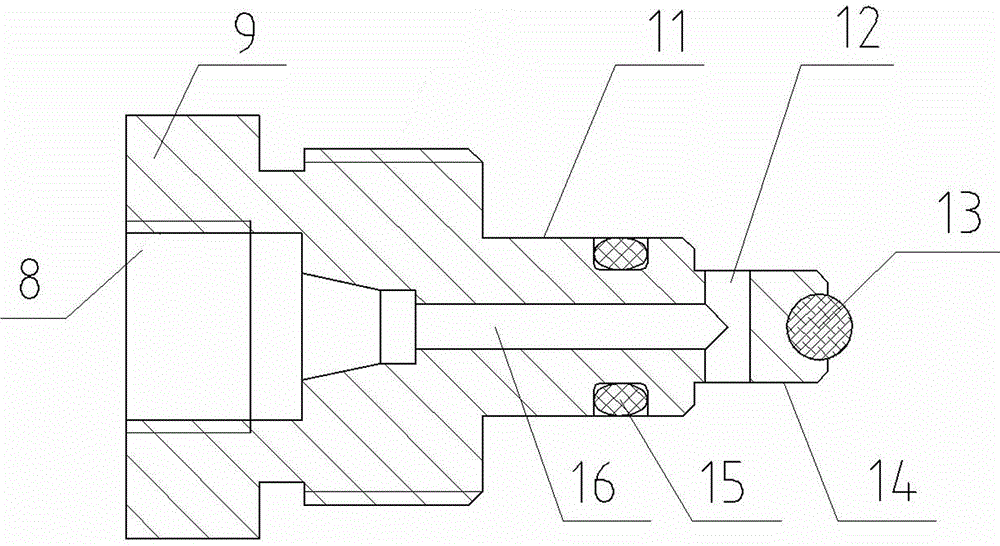

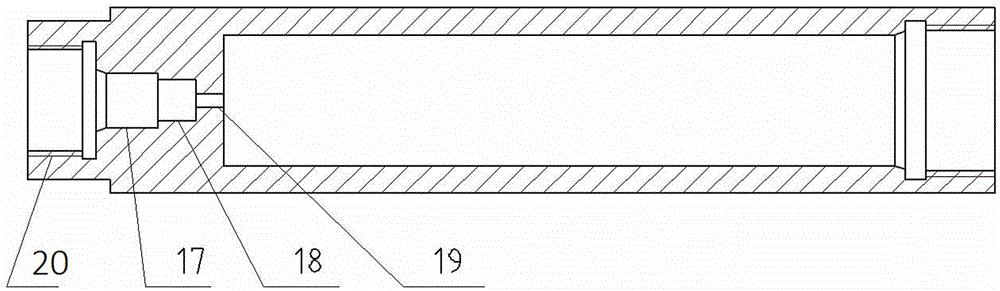

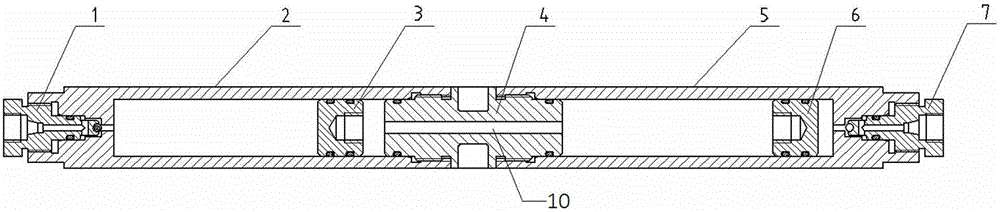

[0011] refer to Figure 1-3 , the liquid pressure-holding sampling cylinder of the present invention comprises a connector 4 arranged on a coaxial line, two cavities 2, 5 and two sampling valves 1, 7, the cavities are cylindrical with one end open, and two The open ends of the cavities 2 and 5 are threadedly connected with the two ends of the connector 4 respectively, and the connector 4 is provided with a communication hole 10, which connects the two cavities 2 and 5, and the two cavities 2 and 5 The other end is provided with stepped through holes, and the stepped through holes are coaxially arranged outer end hole 20, sealing hole 17, diversion groove 18 and diversion hole 19 from the outside to the inside, and the outer end hole 20 is tapped with an internal thread , the sampling valve is composed of a valve body 9 with an external thread, a sealing shaft 11 a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com