Rotary valve type valve rod and control valve

A technology of rotary valve and control valve, which is applied to multi-way valves, valve devices, cocks including cut-off devices, etc. It can solve the problems of high manufacturing cost and difficult processing of rotary valve stems, and achieve easy processing and easy operation. Ease of use and the effect of improving interchangeability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The specific implementation will be described below in conjunction with the accompanying drawings.

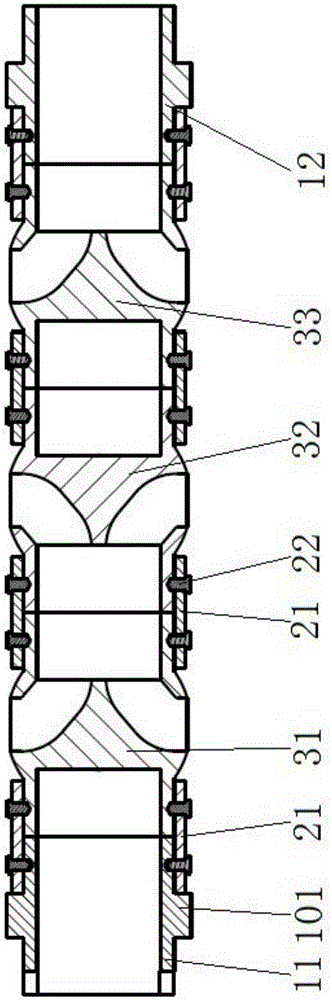

[0025] This embodiment is a rotary valve stem, which can be used for a rotary valve control valve. Such as figure 1 As shown, the rotary valve stem in this embodiment includes five stem segments, and the five stem segments include two positioning segments with the same structure and three stem segments with the same structure and spherical joints The two positioning segments are respectively the left positioning segment 11 and the right positioning segment 12, and the three valve stem segments with spherical joints are the first valve stem segment 31, the second valve stem segment 32, the Three stem segments 33 .

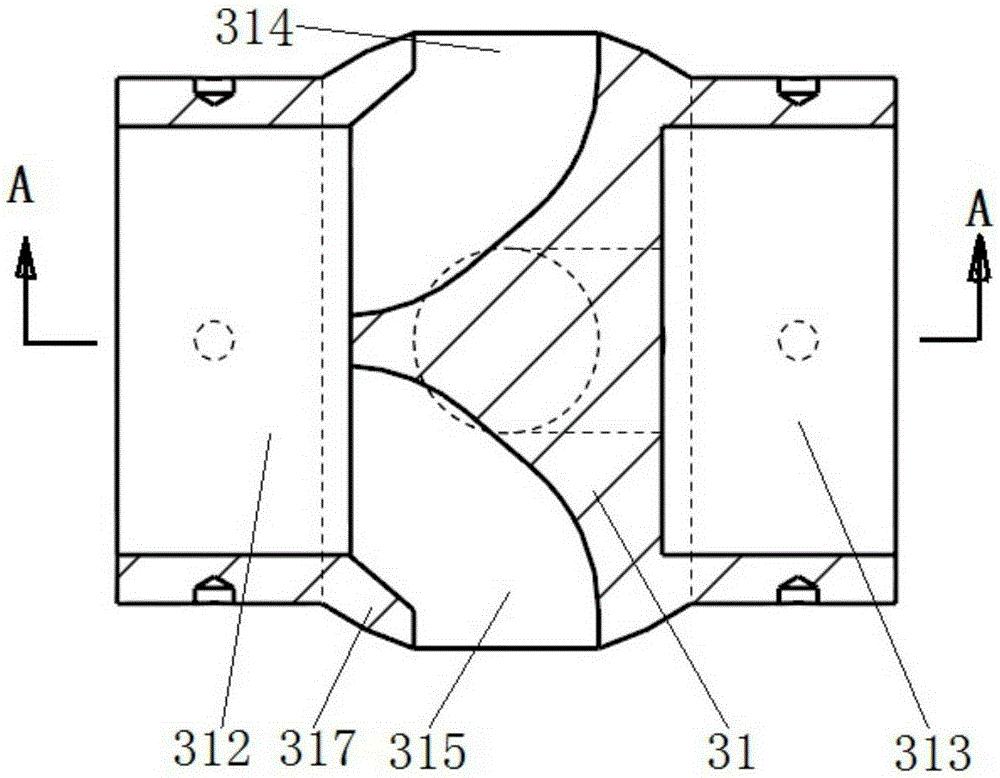

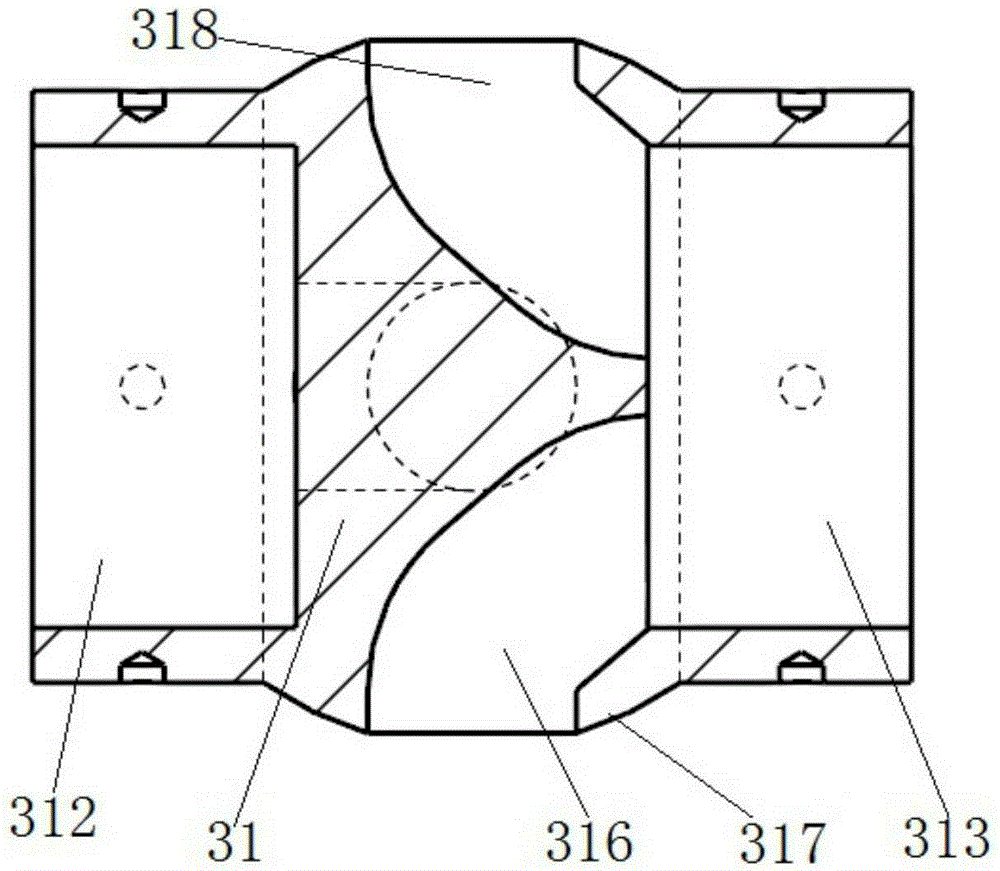

[0026] Such as figure 2 image 3 As shown, there is a spherical joint on the first valve stem section 31, and the spherical joint has a spherical surface 317 surrounding the valve stem section, and four valve stem oil ports are arranged on the spherical s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com