Ventilation stop valve

A technology for cut-off valves and bonnets, applied in safety valves, balance valves, valve devices, etc., can solve problems such as huge gaps in air pressure changes, mutual offset of seals, and insufficient operational stability, to improve sealing performance and motion Stability, reduced suction, easy re-opening effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] the following to Figure 1 to Figure 26 The specific embodiments of the present invention are shown in detail.

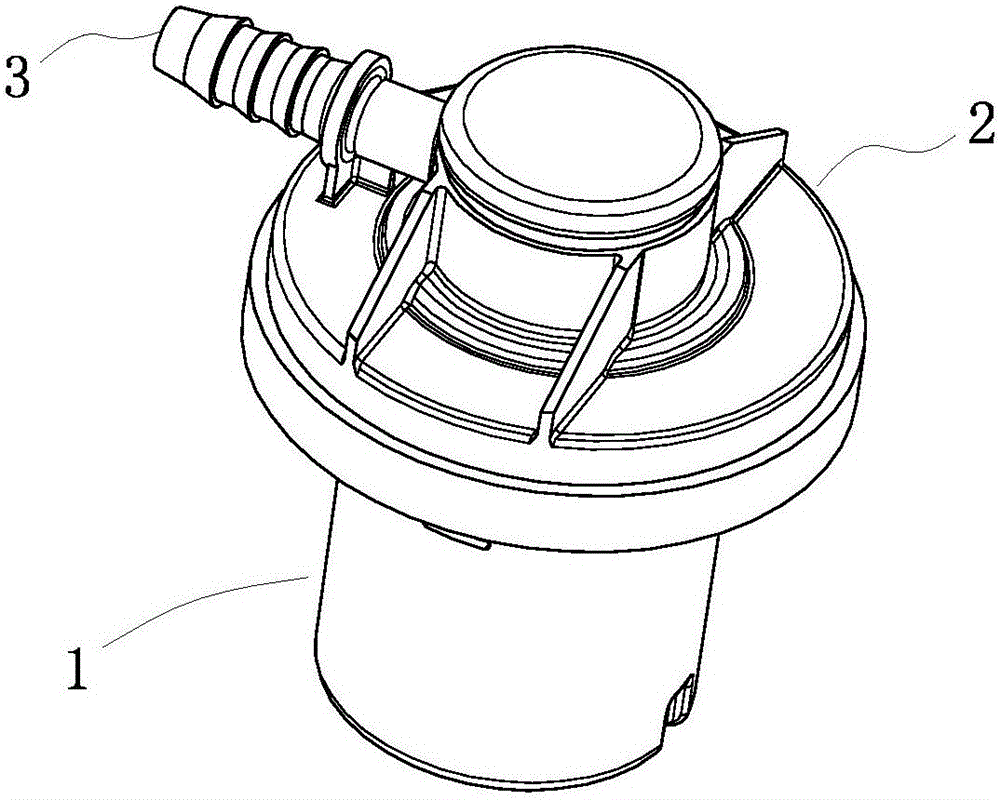

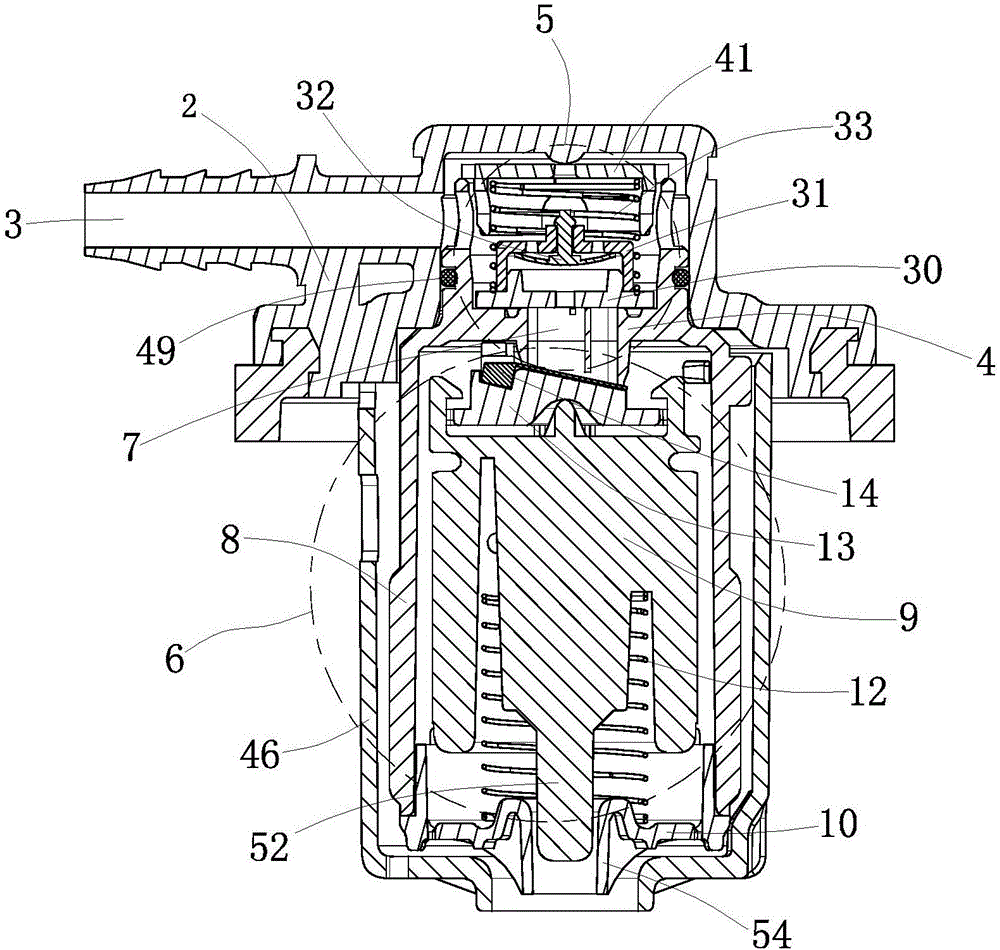

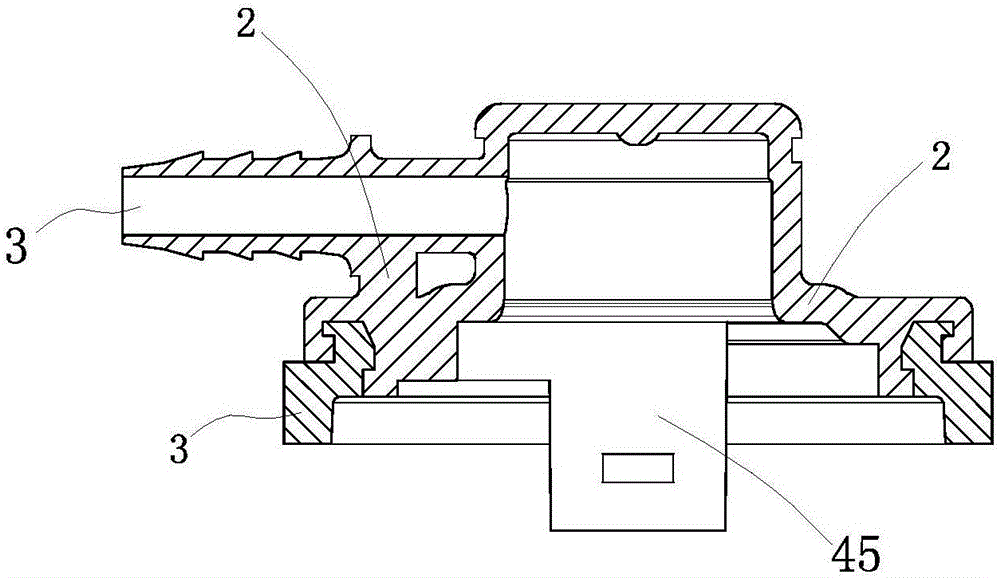

[0045] A vent shut-off valve, such as figure 1 As shown, it includes a valve body 1 and a valve cover 2 , the valve cover 2 is provided with an external port 3 as a fluid passage port, and the valve body 1 is located below the valve cover 2 .

[0046] Such as figure 2 As shown, the valve body 1 includes a housing 8, a vent valve 5 and a shut-off valve 6 arranged inside the housing 8, a partition wall 4 is arranged inside the housing 8, and a vent valve 5 is arranged above the partition wall 4 of the housing 8 to isolate A cut-off valve 6 is arranged below the wall 4, and a fluid passage hole 7 is provided in the partition wall 4, see Figure 10 , Figure 11 , Figure 12 is more clear. The valve cover 2 covers the upper part of the housing 8 and is fixedly connected with the valve cover 2. A floating core 9 which can move up and down along the inner wal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com