Cartridge valve cover plate device

A technology of cover plate device and cartridge valve, applied in the direction of fluid pressure actuation device, servo motor assembly, mechanical equipment, etc., can solve the problems of the influence of the quality of the billet, the damage of the cooling bed equipment, the bending and deformation of the billet, etc., to improve the safety. and continuity, ensuring safe production, and reducing labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

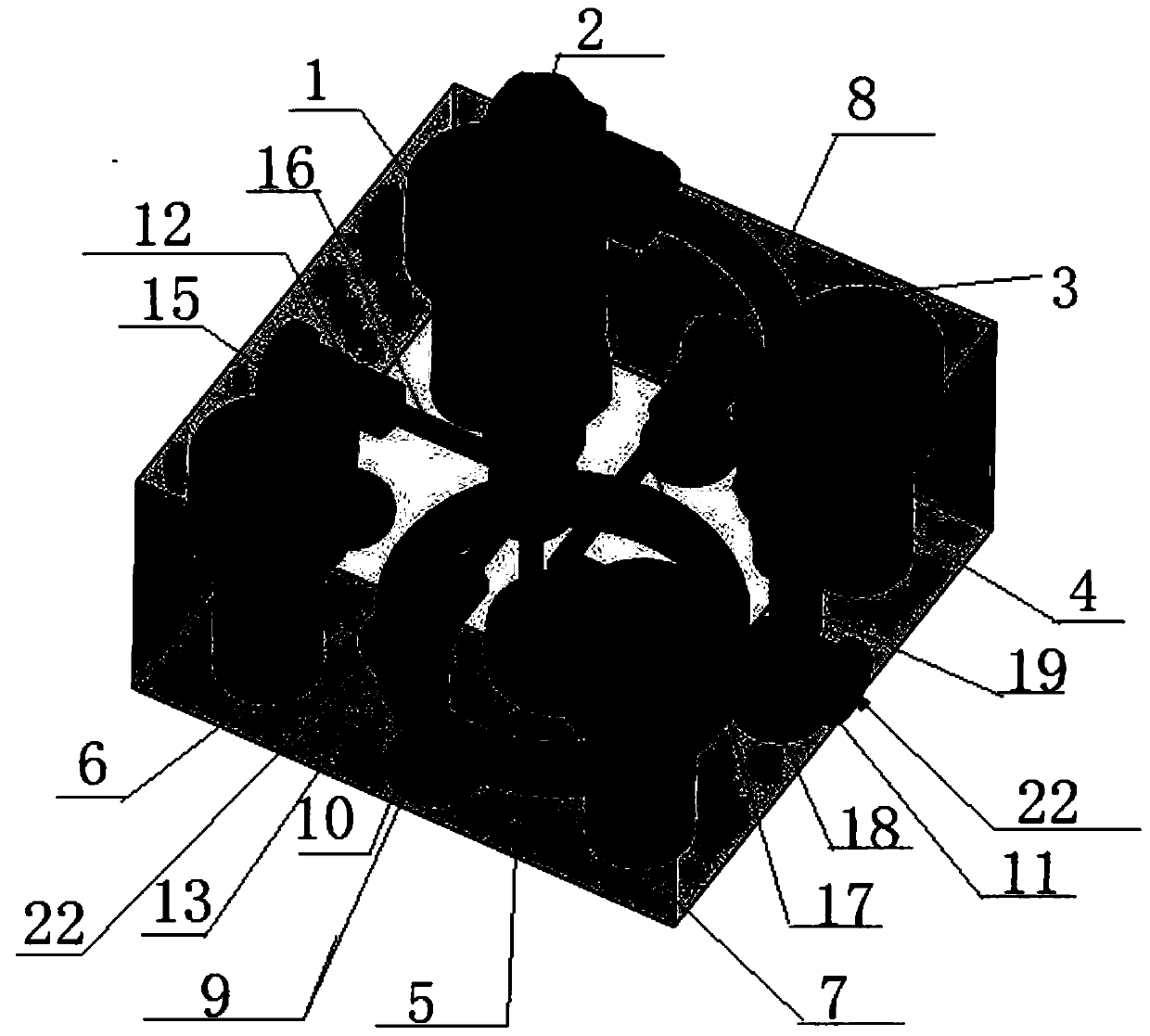

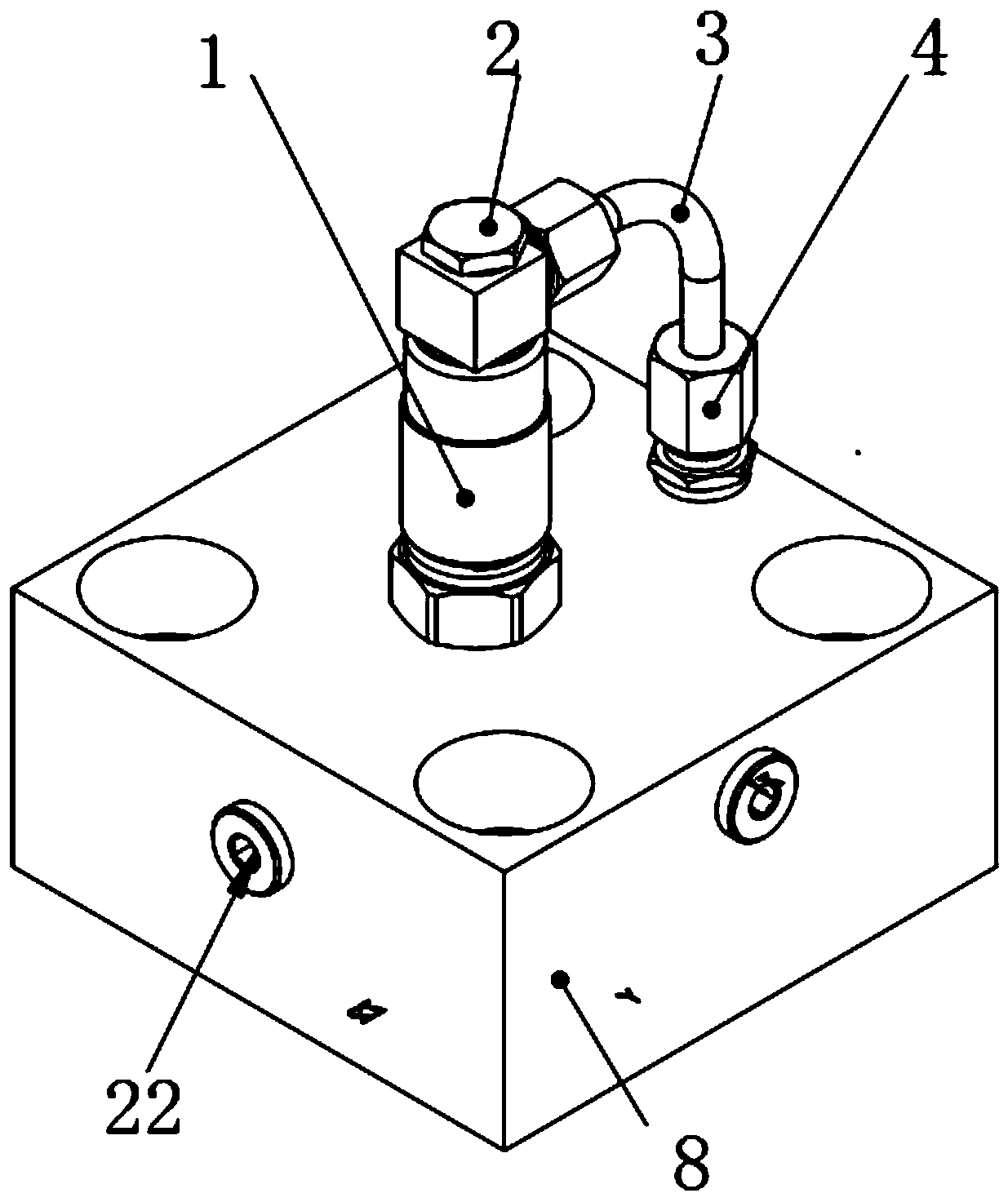

[0032] Such as figure 1 , 2 , 3 and 4, which is a preferred embodiment of the two-way cartridge valve cover device of the present invention, the two-way cartridge valve cover device includes a cover body 8, a threaded cartridge type hydraulic replacement Directional valve 1, external control oil circuit and internal control oil circuit;

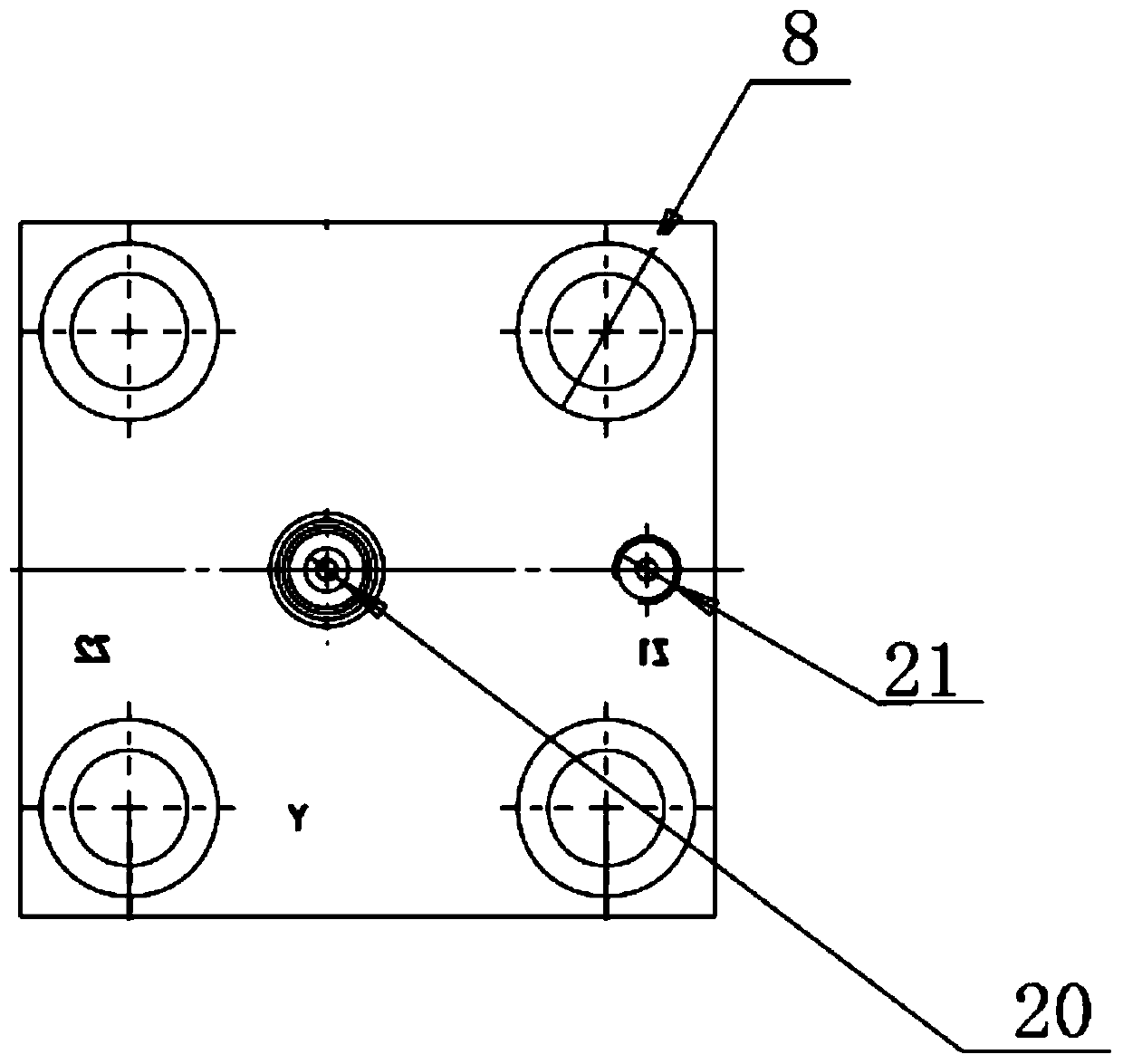

[0033] The cover plate body 8 is provided with a first through hole 20 and a second through hole 21, and the inside of the cover plate body 8 is provided with an internal control oil circuit; the bottom of the threaded plug-in hydraulic reversing valve 1 is inserted into the first through hole The socket 20 is connected with the internal control oil circuit; the bottom of the cover plate body 8 is provided with a through hole for connecting with the cavity 14 of the bottom plate of the valve body, and the connection is provided with a sealing device;

[0034] The external control oil circuit includes X pilot control oil circuit 3;

[0035]...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com