Car pilot-operated type fuel pump pressure regulator

A pilot-operated, fuel pump technology, applied in machine/engine, liquid fuel feeder, engine components, etc., can solve problems such as poor pressure characteristics, inability to match system pressure well, system pressure reduction, etc., to achieve pressure characteristics Good, low production cost, good pressure holding performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

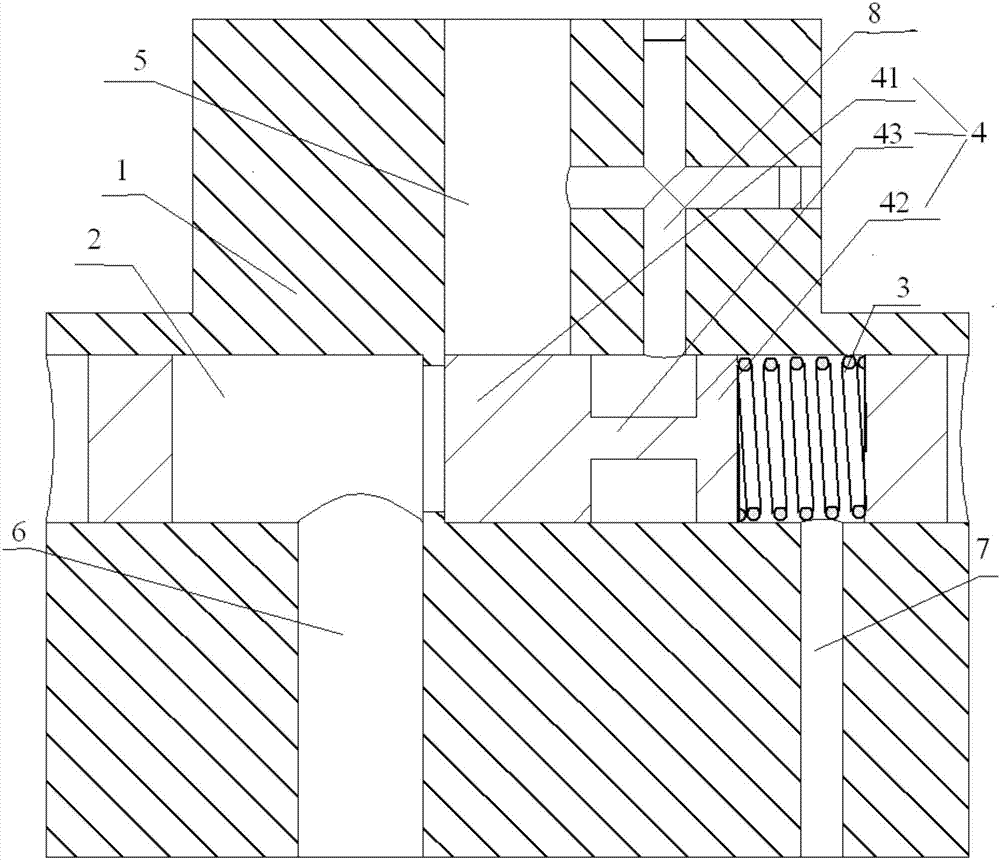

[0013] Example 1, such as figure 1 As shown, the automotive pilot fuel pump pressure regulator consists of valve body 1, fuel channel 2, pressure regulating spring 3, spool 4, oil inlet channel 5, first oil outlet channel 6, second oil outlet channel 7, bypass channel 8 composition.

[0014] The middle part of the valve body 1 is provided with a fuel channel 2 extending left and right, and the two ends of the fuel channel 2 are sealed. The valve body 1 below the fuel passage 2 is also provided with a first oil outlet passage 6 and a second oil outlet passage 7 whose axis extends up and down from left to right, and the upper ends of the first oil outlet passage 6 and the second oil outlet passage 7 are connected to The fuel oil channel 2 communicates, the oil inlet channel 5 is located between the first oil outlet channel 6 and the second oil outlet channel 7, the inner diameter of the second oil outlet channel 7 is smaller than the inner diameter of the first oil outlet chann...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com