Gas-liquid balancing device for vertical ram milling head

A column and gantry milling machine technology, applied in the hydraulic field, can solve the problems of poor stability of the hydraulic balance system, and achieve the effects of low procurement cost and use cost, avoiding mechanical accidents and small temperature rise.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments. The following description is only exemplary and does not limit the protection scope of the present invention.

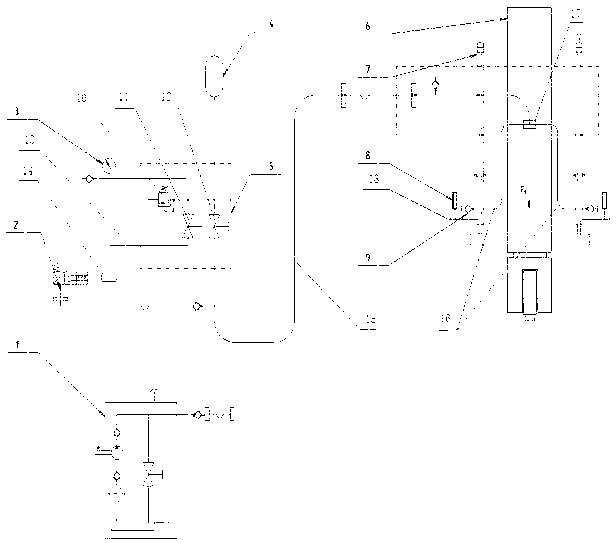

[0026] Reference attached figure 1 , a gas-liquid balance device for a vertical ram milling head, comprising two balance cylinders 7, an accumulator 4 and an overflow throttling structure; the two balance cylinders 7 are respectively arranged on both sides of the ram milling head 6; The accumulator 4 is connected to the oil outlet pipelines 16 of the two balance cylinders 7 through a main pipeline 15 through a three-way connection mechanism 17, and the accumulator 4 is provided with an oil discharge branch 13 with a pressure gauge 3, and the oil discharge branch The outlet of the road 13 is connected with an oil tank 14; the overflow and throttling structure 5 includes a safety valve 10, a first control valve 11 and a second c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com