Ratchet device with ratchet gear teeth equipped with tooth sleeves

A technology of ratchet device and gear sleeve, which is applied to components with teeth, hoisting device, portable lifting device, etc., which can solve the problem of easy wear of ratchet gear teeth and pawls, cutting off ratchet gear teeth, and short service life, etc. problem, achieve the effect of reducing shear force, reducing impact force and avoiding mechanical accidents

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

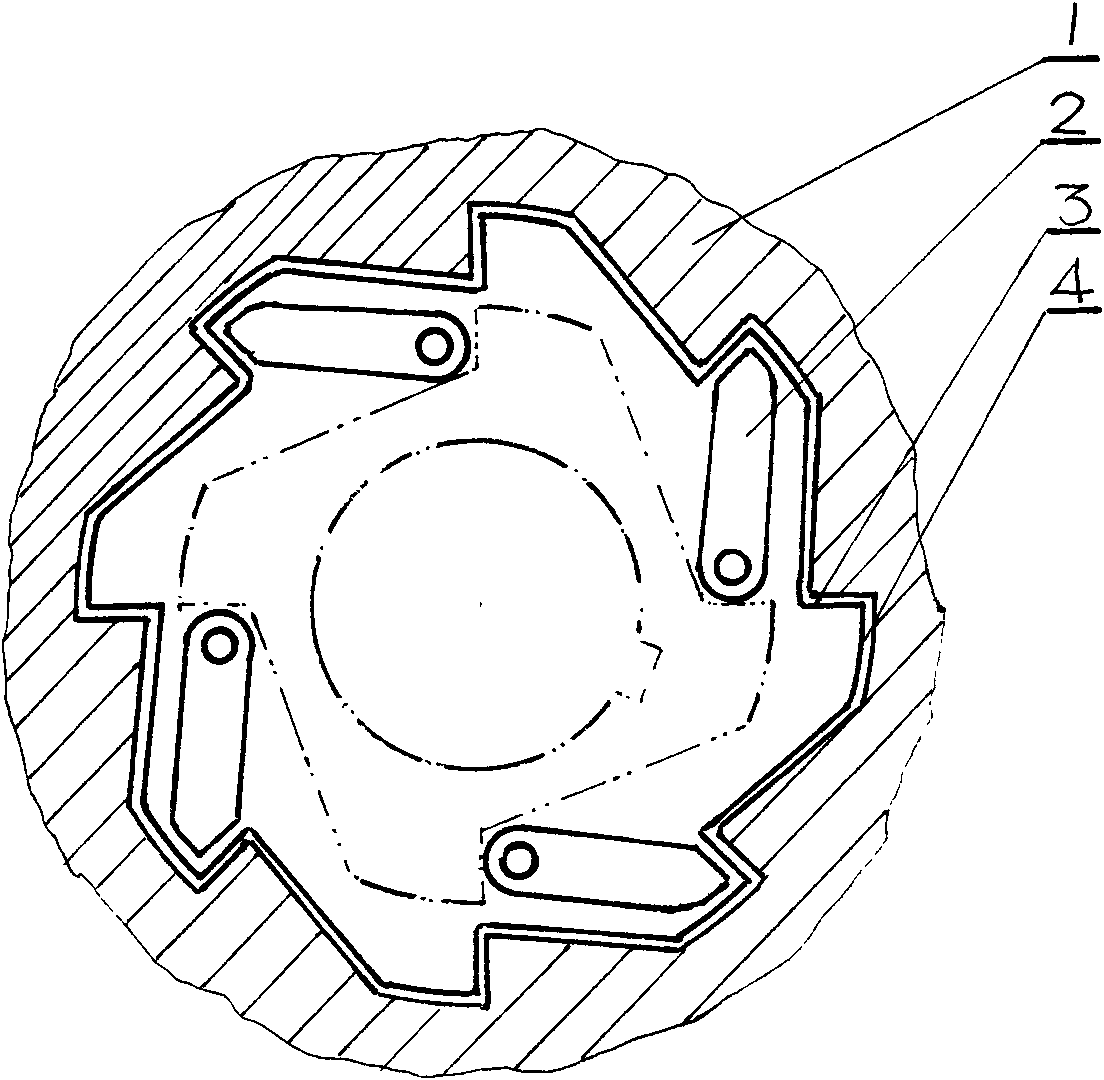

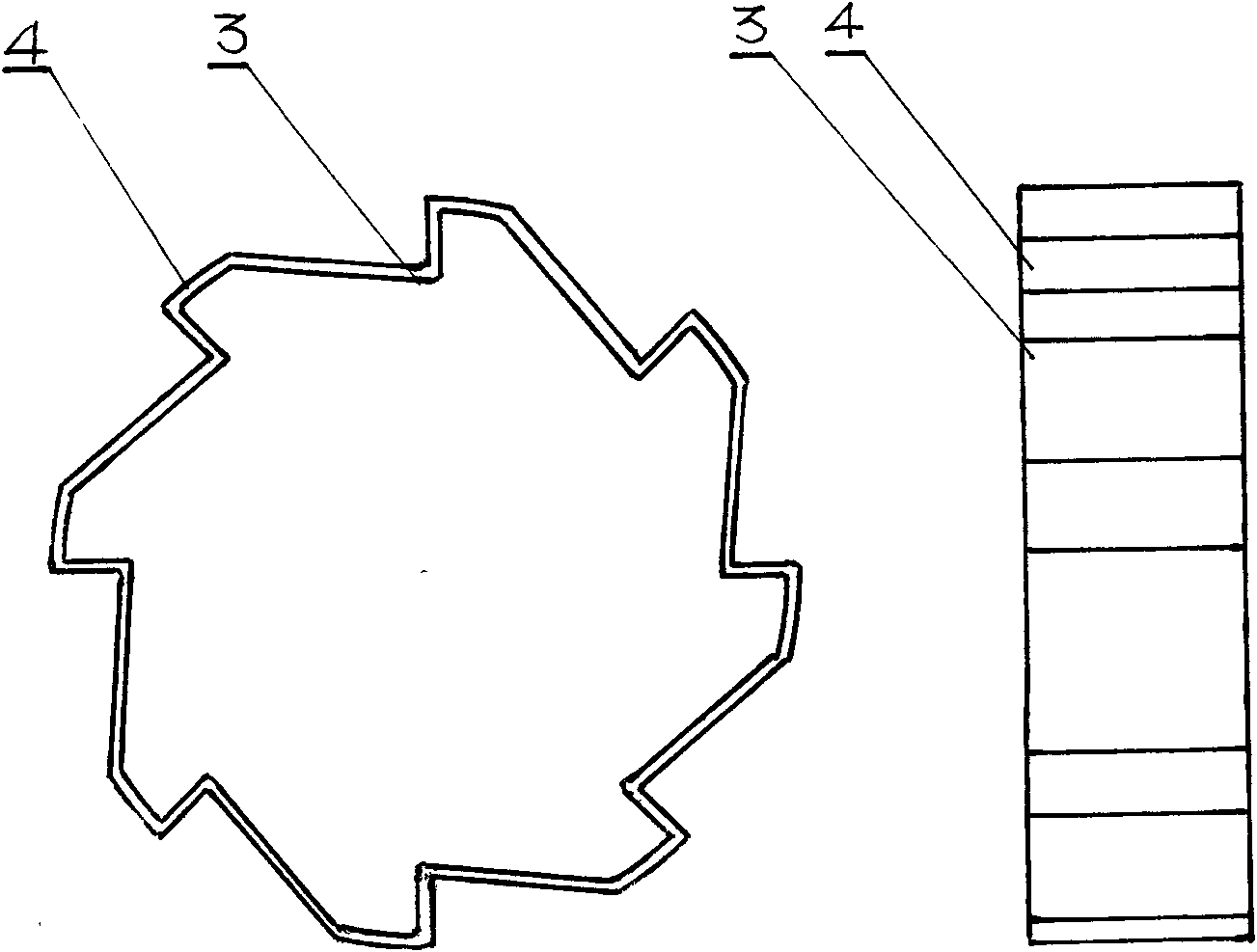

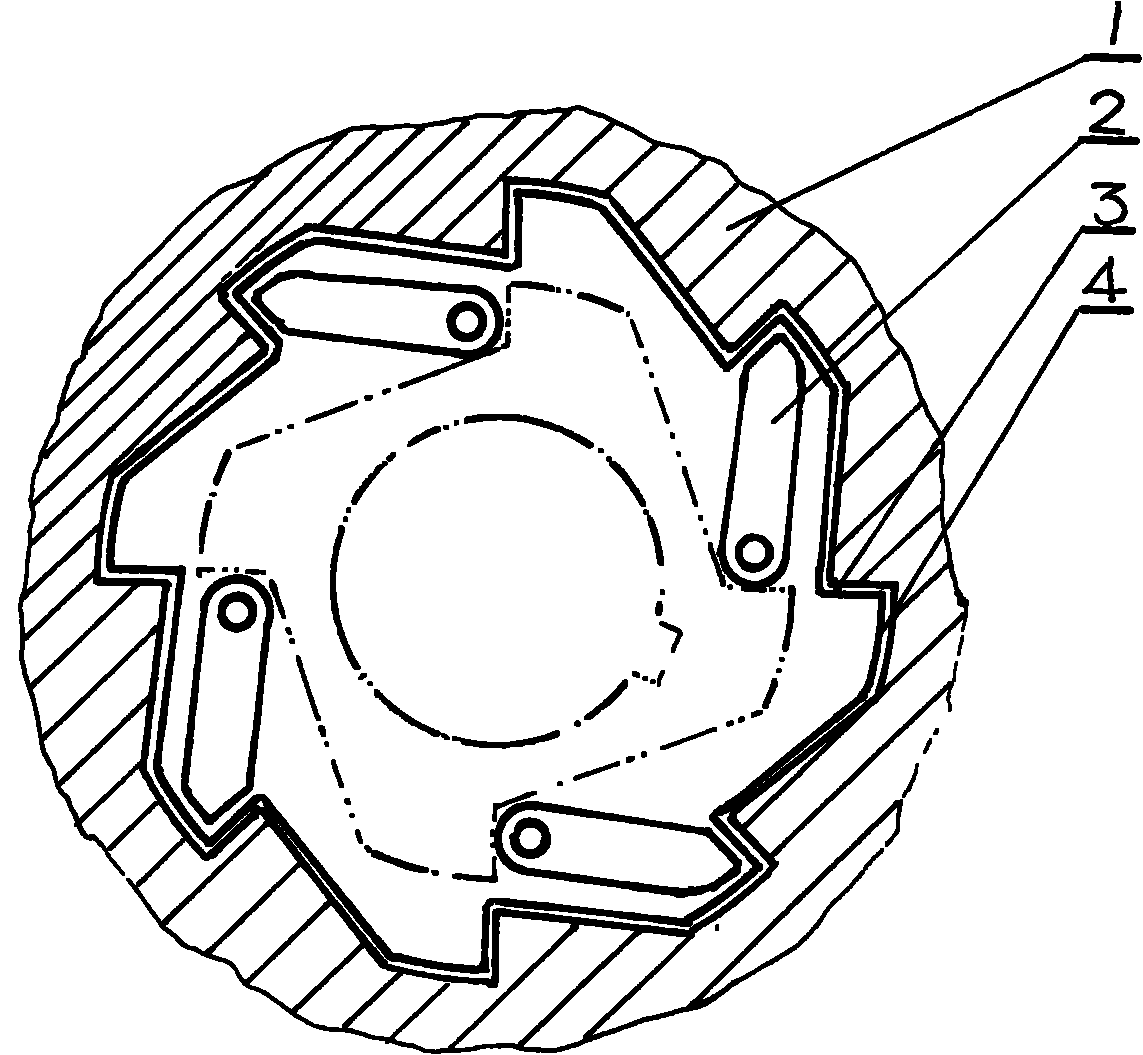

[0011] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

[0012] First, according to the shape and size of the gear teeth and the inner ring of the ratchet 1, process a single part that is integrated with the gear sleeve 3 and the connecting piece 4 with a suitable process, and then insert this part on the gear teeth and the inner ring of the ratchet 1. On the ring, welding or bonding technology can be used to make the inlay more firm. After being put into use, the ratchet 2 no longer contacts the gear teeth of the ratchet 1, but contacts the gear teeth through the tooth sleeve 3, so that the ratchet gear teeth are well protected. Through the use of a maintenance cycle, the gear sleeve 3 is normally worn to the point where it needs to be replaced, as long as the old gear sleeve 3 and the connecting piece 4 are folded off, and a new one is replaced. The folding operation takes only a short time and co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com