Color-changing device of computer embroidery machine

An embroidery machine and computer technology, which is applied in the field of computerized embroidery machine color changing devices, can solve the problems of low edge definition of embroidery patterns, unclear color levels, and low embroidery quality, so as to improve work efficiency and quality, and ensure Accuracy, the effect of avoiding mechanical accidents

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] Below in conjunction with accompanying drawing and embodiment the present invention will be further described:

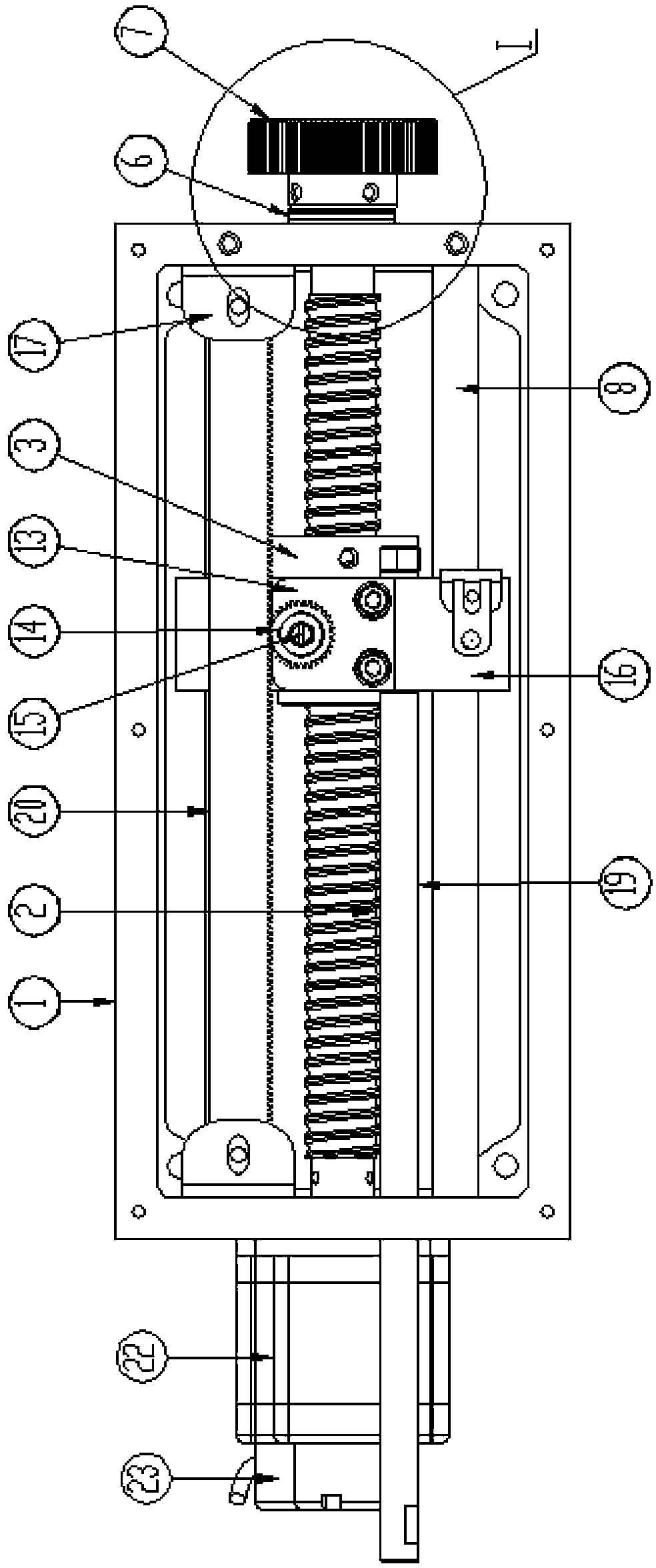

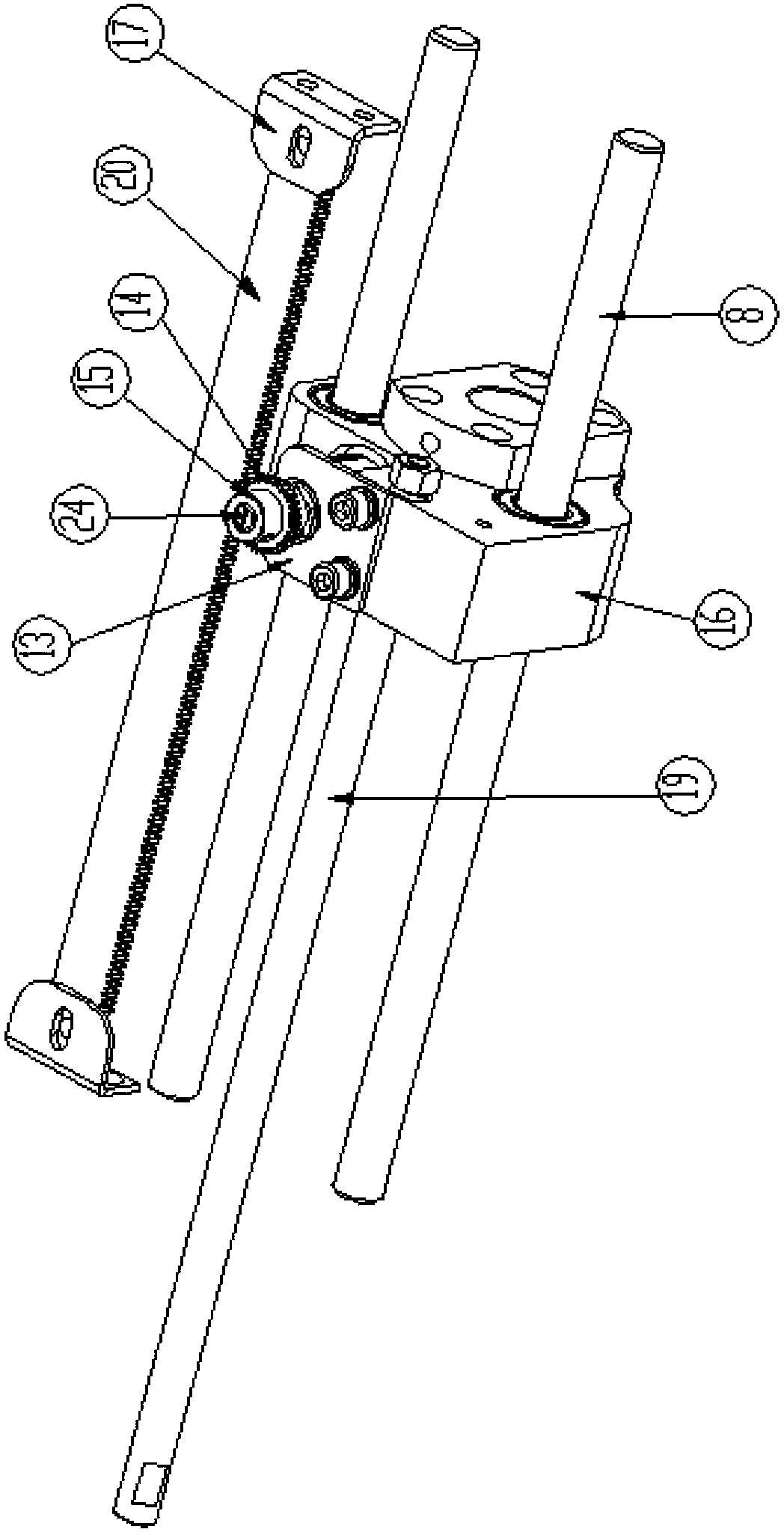

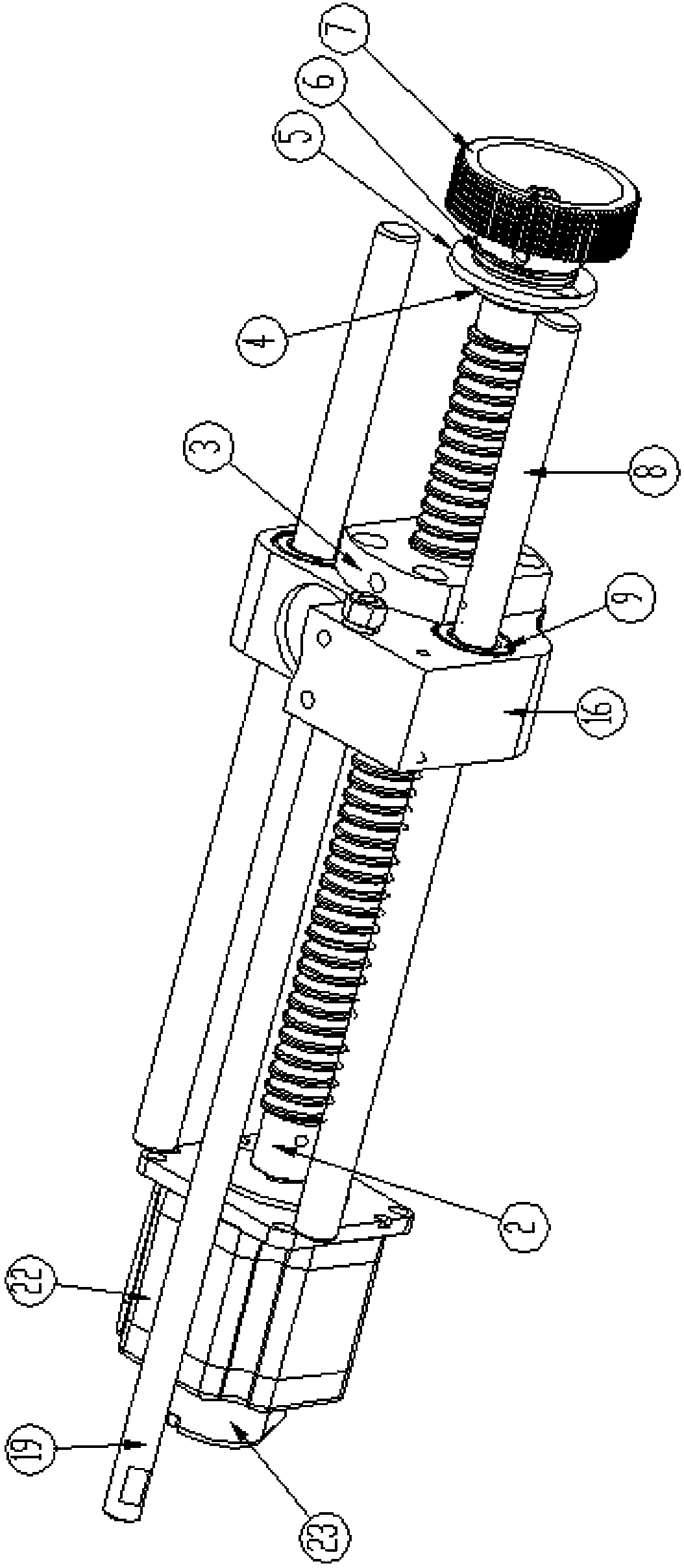

[0029] Such as Figure 1-3 As shown, the color changing device of the present invention includes a needle bar frame driving device and a needle position signal collecting device.

[0030] The present invention preferably following structure is used as needle bar holder driving device: it comprises push rod 19, driving seat 16, screw nut pair, guide rail 8 and the stepping motor 22 that drive screw rod rotates. The driving seat 16 is slidingly connected with the guide rail 8 and fixedly connected with the nut. One end of the push rod 19 is fixedly arranged on the driving seat 16, and the push rod 19 is arranged in parallel with the guide rail 8, and the other end of the push rod passes through the through hole on the casing and is fixedly connected with the needle bar frame. One end of the screw rod is fixedly connected with the box body 1 through a bearing,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com