Power-assist cotton-pulling mechanism for cotton fiber scutching machine single-roller feeding cotton

A bomb cleaning machine, cotton fiber technology, applied in fiber cleaning machine, fiber processing, fiber feeding and other directions, can solve the problems of block fiber accumulation, cotton stick entanglement, cotton feeding difficulty, etc., to eliminate mechanical Accident, flexible operation, simple and compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

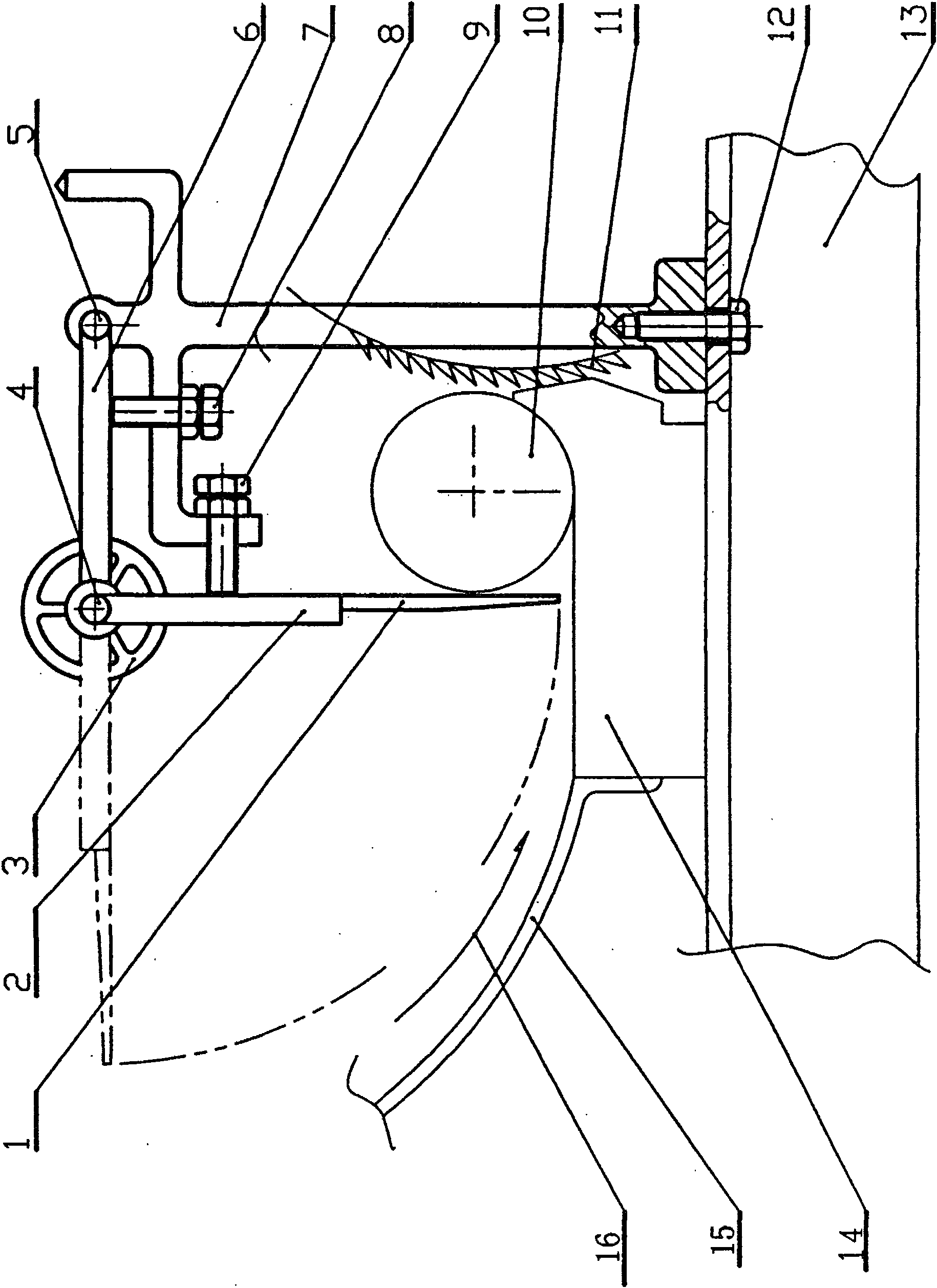

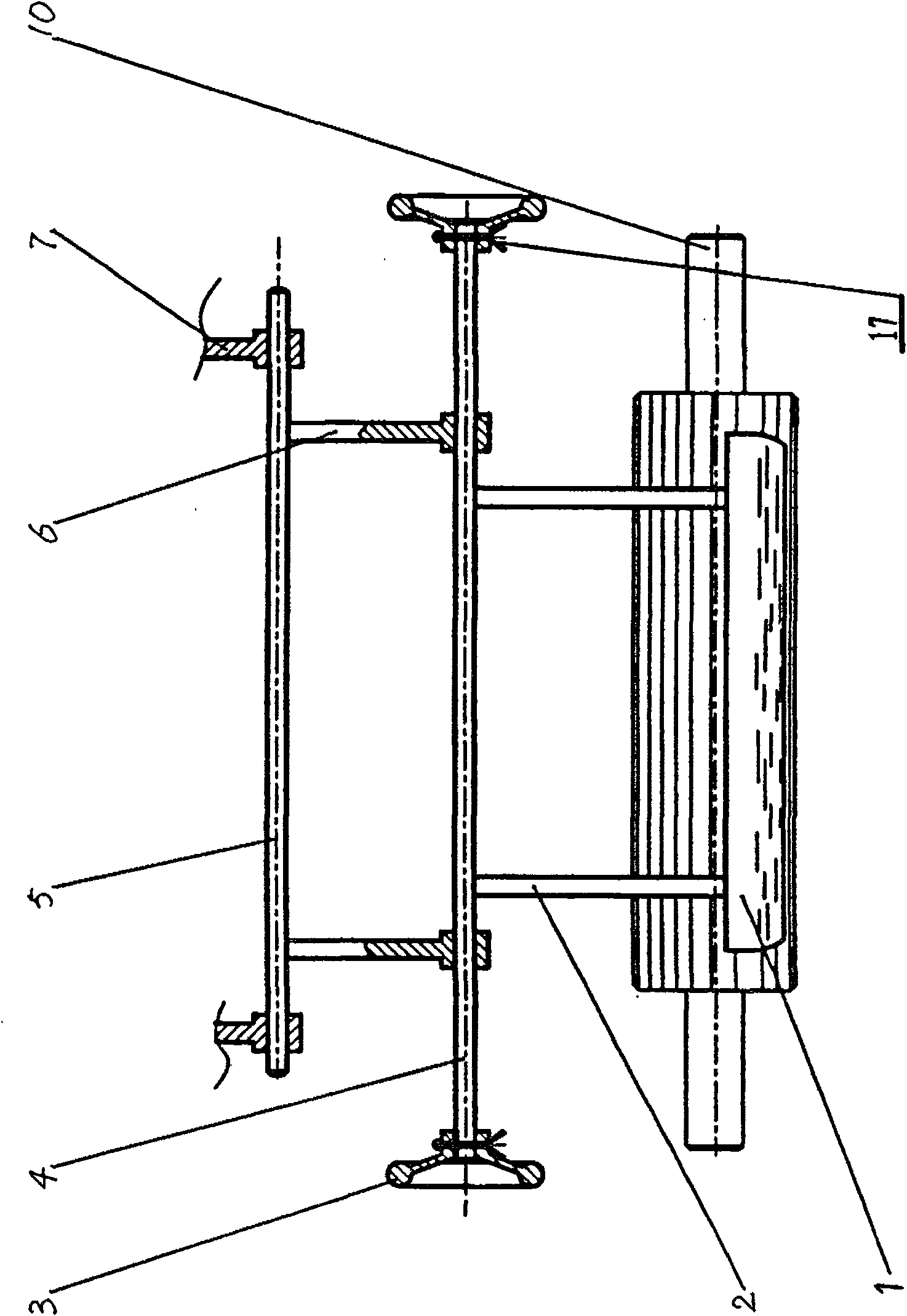

[0010] The specific embodiment of the present invention will be further described in conjunction with the accompanying drawings. The examples are intended to illustrate the invention without limiting it in any way.

[0011] The present invention consists of dial 1, connecting rod one 2, connecting rod two 6, handwheel 3, pin 17, rotating shaft one 4, rotating shaft two 5, support 7, longitudinal adjustment screw 8, lateral adjustment screw 9 and screw 12 , matched to be installed on the cotton fiber bomb cleaning machine with single roller feeding cotton type. The bomb cleaning machine includes a cotton feeding roller 10, a licker-in roller 11, a cotton feeding plate 14, a supporting plate 15 and a frame 13. Two bearings 7 of the present invention are respectively fixed on the frame 13 of licker-in roller 11, cotton feeding roller 10 and cotton feeding board 14 by screw 12, or are fixed on the object that frame 13 both sides are still and does not rotate, and the bearing The...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com