Fabricated steel-concrete composite structure formwork-free floor slab

A combined structure and formwork-free technology, applied to truss structures, floor slabs, structural elements, etc., can solve problems such as high construction cost, complicated construction process, and slow progress of the project

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The invention will be further described below in conjunction with the accompanying drawings.

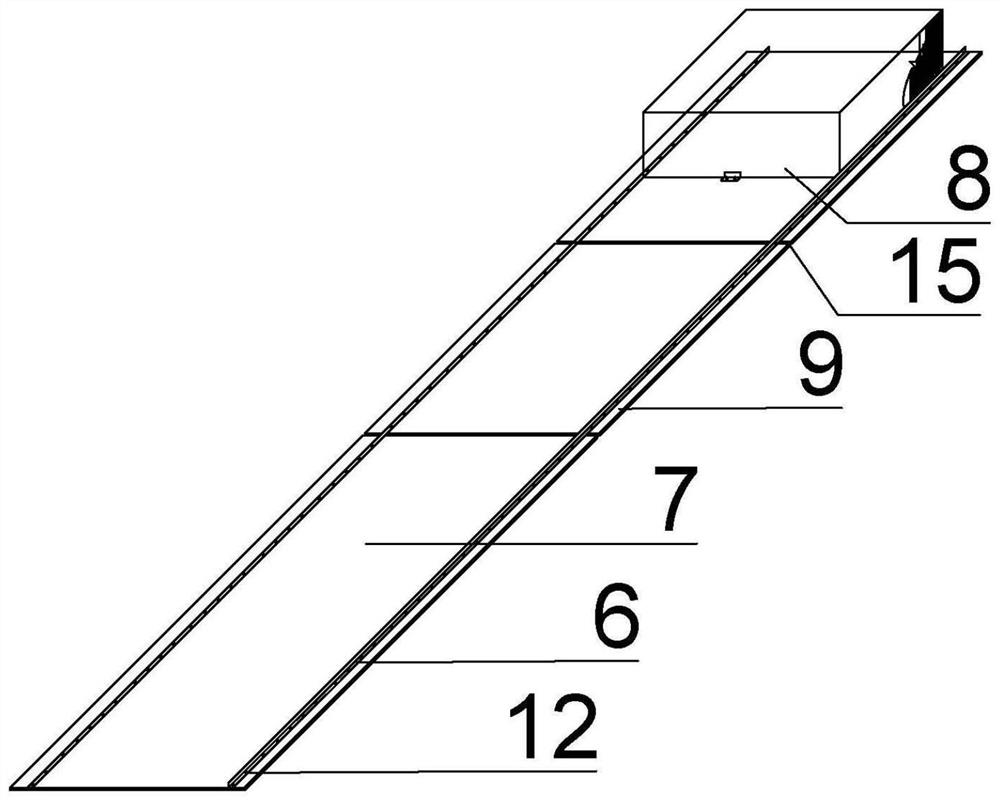

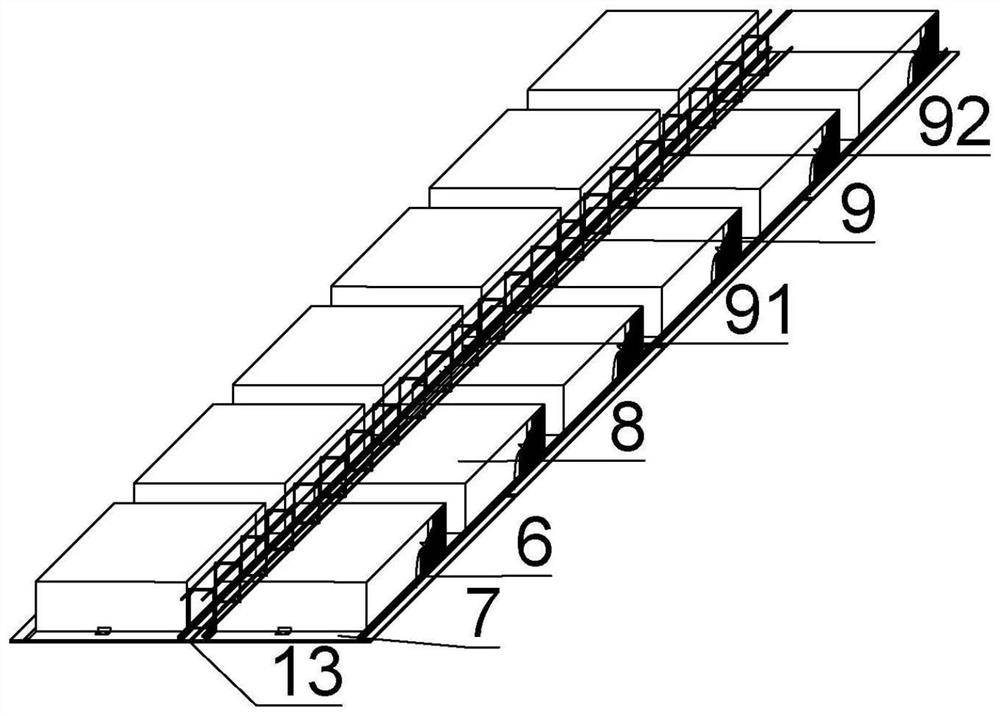

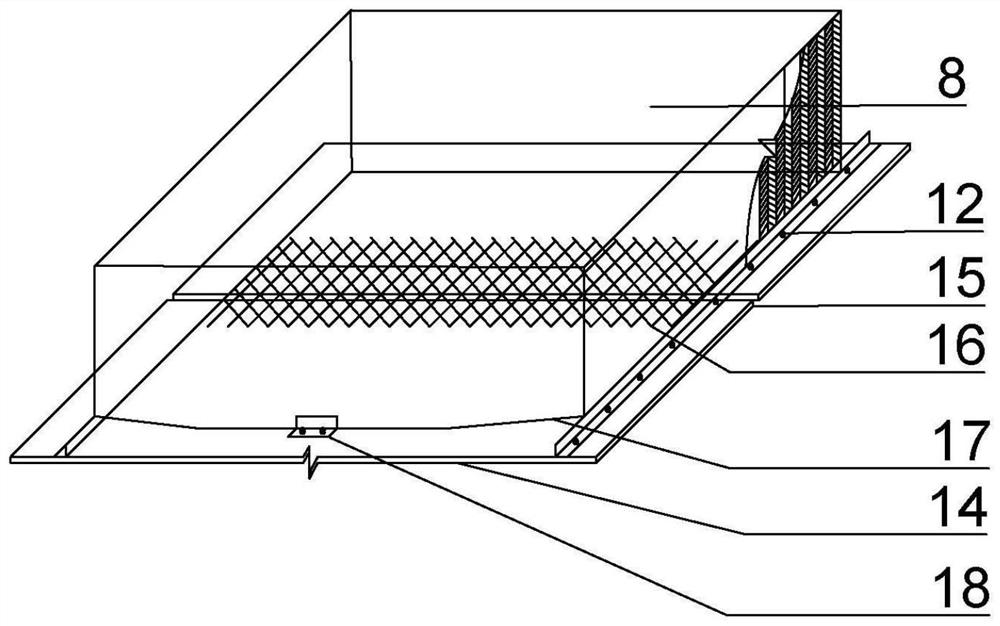

[0020] figure 1 It is a schematic diagram of the single block bottom mold assembly of the present invention, as figure 1 As shown, reinforced fiber cement is used in the factory to produce rigidity and softness under the action of special equipment, at least one side is rough, its thickness is ≤20mm, and the density is less than 1600kg / m 3 Inorganic composite boards, the joint joints 15 of N inorganic composite boards are combined into a strip-shaped bottom mold assembly 7 through connecting angle steel 6; the width of each strip-shaped bottom mold assembly is the width of the longitudinal rib beam 9 and the built-in mold 8 The sum of the widths; the optimal size of the width of the bottom mold assembly 7 is 1100mm; the angle steel 6 for connection is placed at 100mm on both edges of the bottom mold assembly, and after the inorganic composite boards are assembled to reach the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com