Cast-in-place concrete pile expanding equipment and construction method of cast-in-place concrete pile

一种施工方法、混凝土的技术,应用在钻孔设备和方法、土方钻采、钻井设备等方向,能够解决施工效率低、破土能力差等问题,达到兼顾破土能力、增加破土面积、容易破土和沉管的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

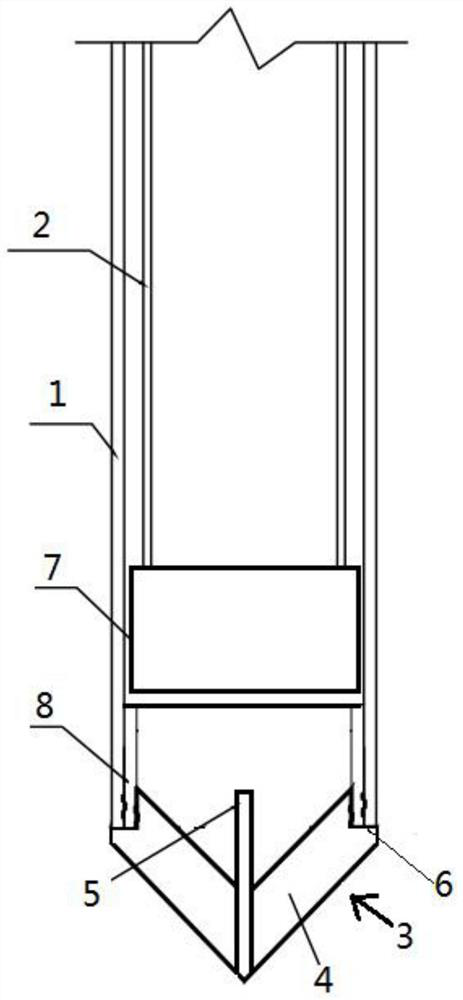

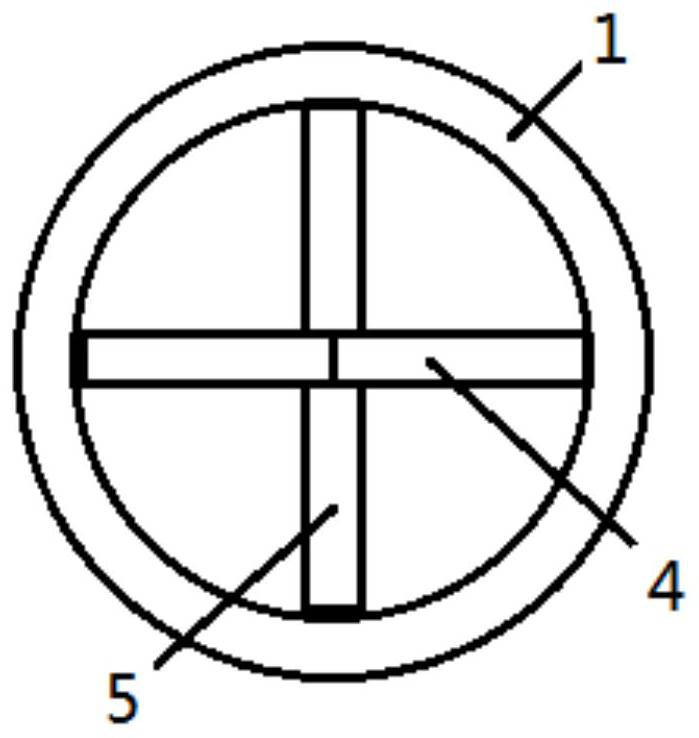

[0036] The invention provides a construction method of a concrete cast-in-place pile, comprising the following steps:

[0037] a. Use the expanding equipment described in the above embodiment 1 to form a hole at the pile position, and sink it to the first expanding position;

[0038]b. Pour fluid plastic concrete at the first diameter expansion position, and apply a vertical downward force to the fluid plastic concrete at the first diameter expansion position by operating the diameter expansion device, radially extruding and expanding the fluid-plastic concrete to form a first diameter-expanding structure;

[0039] c. Using the diameter-expanding device to apply a downward force to the fluid-plastic concrete at the first diameter-expanding position, and while radially extruding and expanding the fluid-plastic concrete, penetrate the fluid-plastic concrete. Flow-plastic concrete body;

[0040] d. sink the expanding device down to the second expanding position;

[0041] e. Po...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com