Vortex shedding flowmeter suitable for corrosive medium

A technology of vortex flowmeter and corrosive medium, which is applied in the direction of volume measurement, volume/mass flow generated by mechanical effects, measurement flow/mass flow, etc., to achieve the effect of avoiding damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

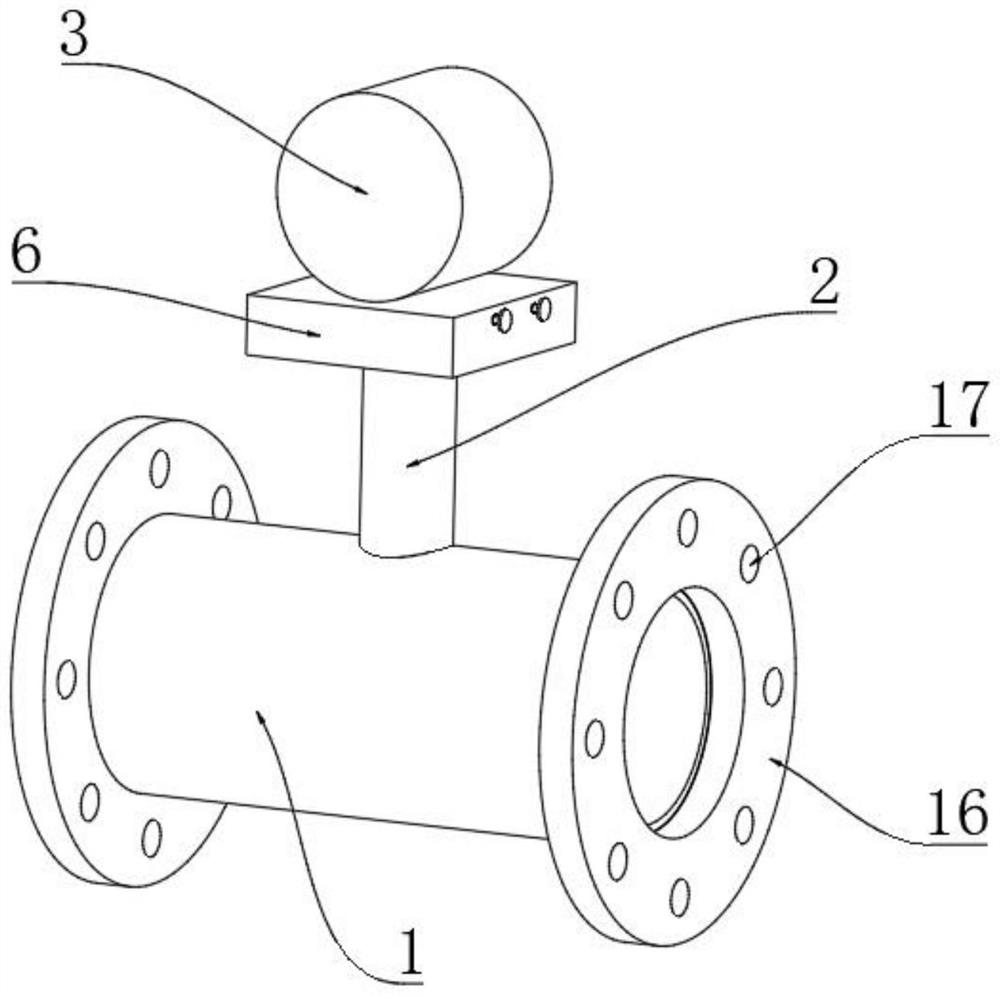

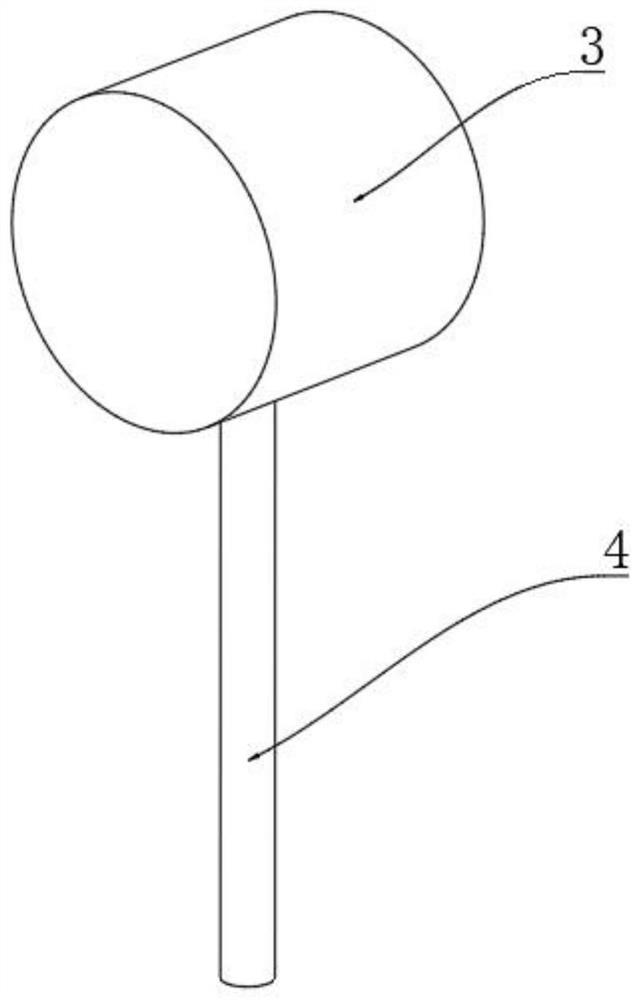

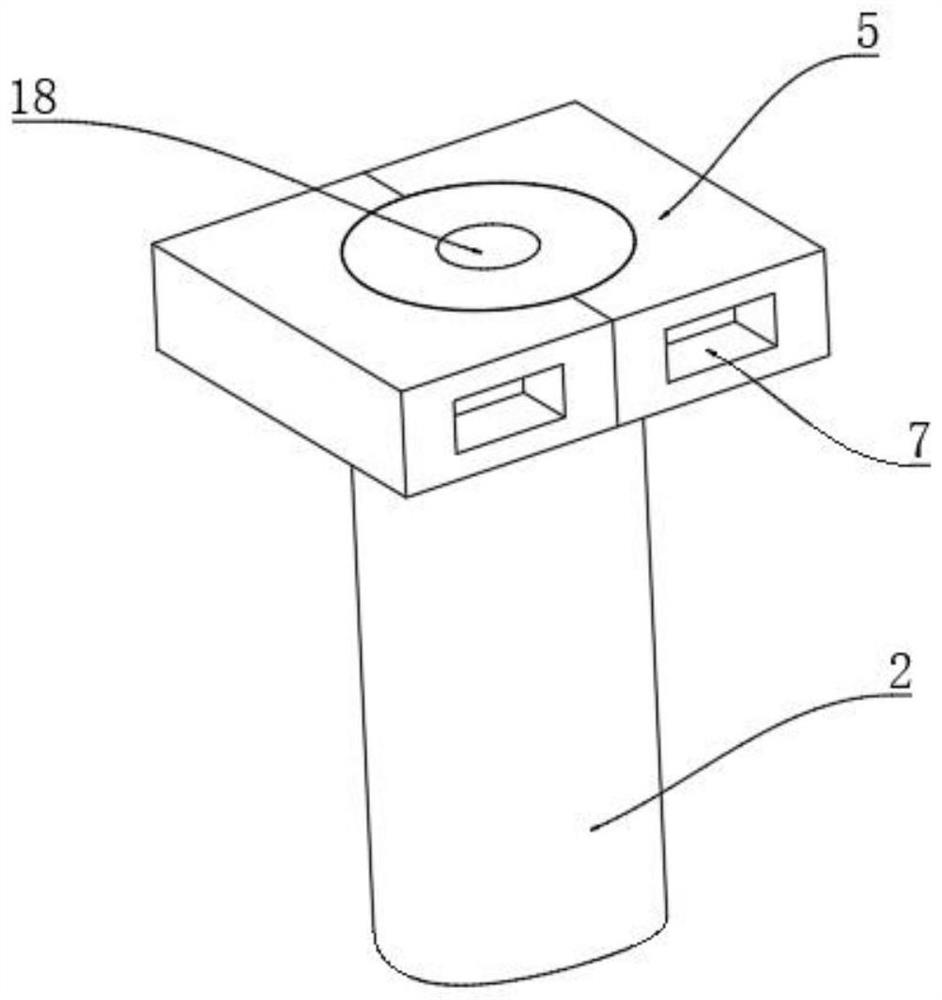

[0028] as Figure 1-6As shown, the present invention provides a vortex flowmeter suitable for corrosive media, including a tube body 1, a pipe body 1 top fixed installation support rod 2, a support rod 2 with a flowmeter body 3 at the top, a flowmeter body 3 bottom surface fixed installation signal line 4, a support rod 2 above the two sides of the symmetrical fixed installation fixed installation block 5, a fixed block 5 wrapped support rod 2, a fixed block 5 with card slots on both sides 7, a flowmeter body 3 bottom surface fixed installation fixed mounting plate 6, a fixed plate 6 bottom surface is opened with and two fixed blocks 5 size suitable for the fixed groove 8, Convenient two fixing blocks 5 can be placed in the fixing slot 8, the bottom of the fixing slot 8 is symmetrically opened with a bottom slot 9, the bottom slot 9 is opened on both sides of the inner wall of the side slot 10, the side slot 10 is equipped with an axial displacement and the card slot 7 adapted to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com