A kind of dynamic grating pattern generation method and system for 3D measurement

A dynamic grating and pattern technology, applied in the field of optics and electronics, can solve the problems of complex system, low optical utilization rate, low brightness, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

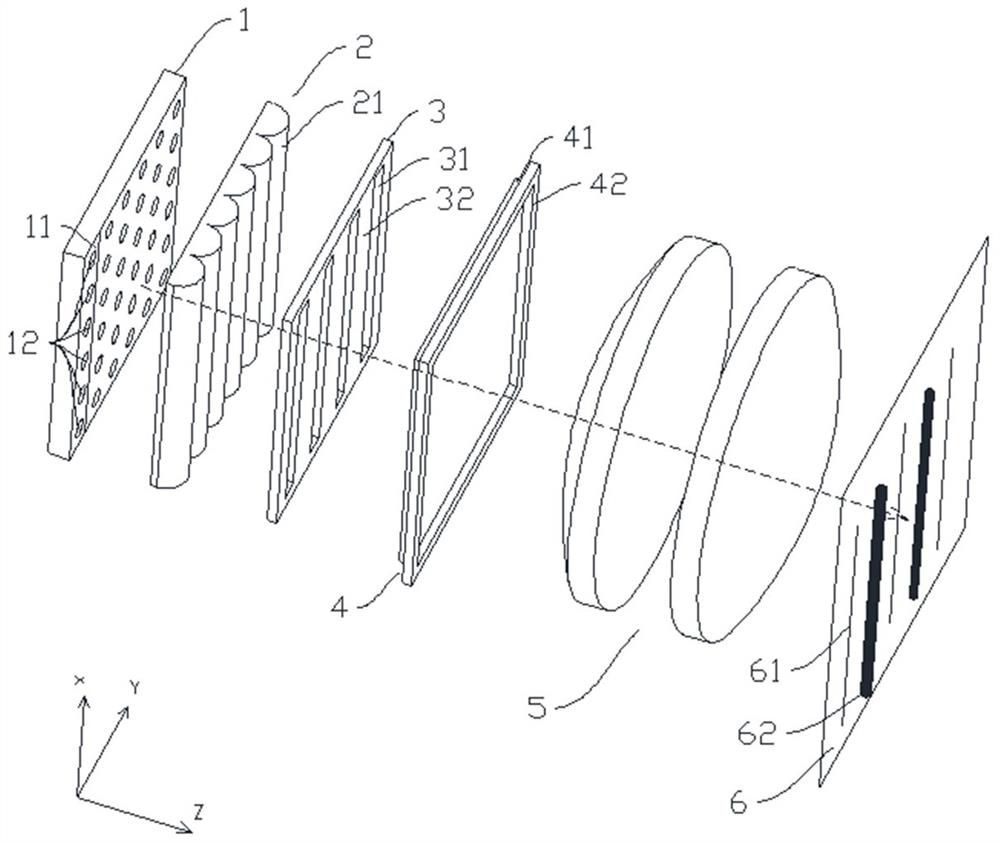

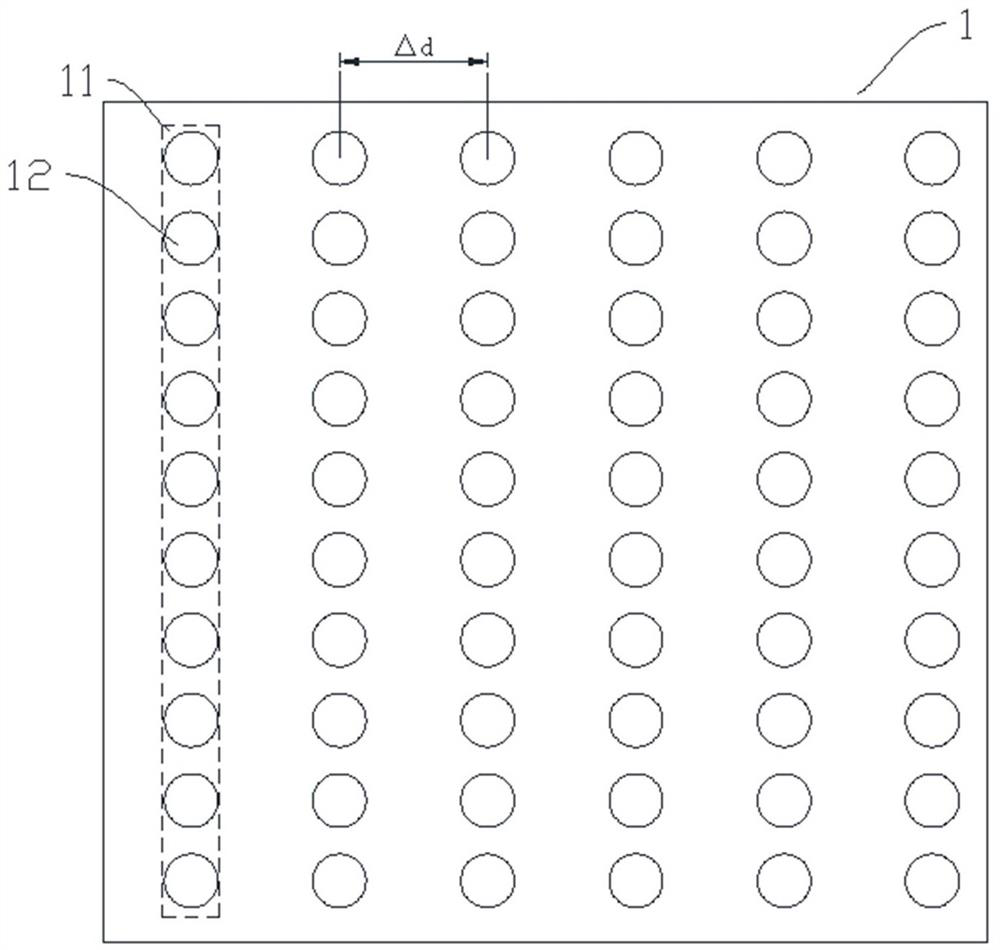

[0059] as attached figure 1 to the attached Image 6 As shown, an embodiment of the present invention provides a dynamic grating pattern generation system for 3D measurement, including a light-emitting unit array 1 for emitting high-frequency stroboscopic light, and the light-emitting unit array 1 includes a number of parallel and spaced light-emitting units 11. Each light-emitting unit 11 can be independently controlled, and the number of light-emitting units 11 can be 50, 100, etc. The specific number is set according to the required resolution.

[0060] Define the plane where the light-emitting unit array 1 is located as the reference plane, with the X-axis direction and the Y-axis direction perpendicular to each other, and define the light propagation path as the Z-axis direction;

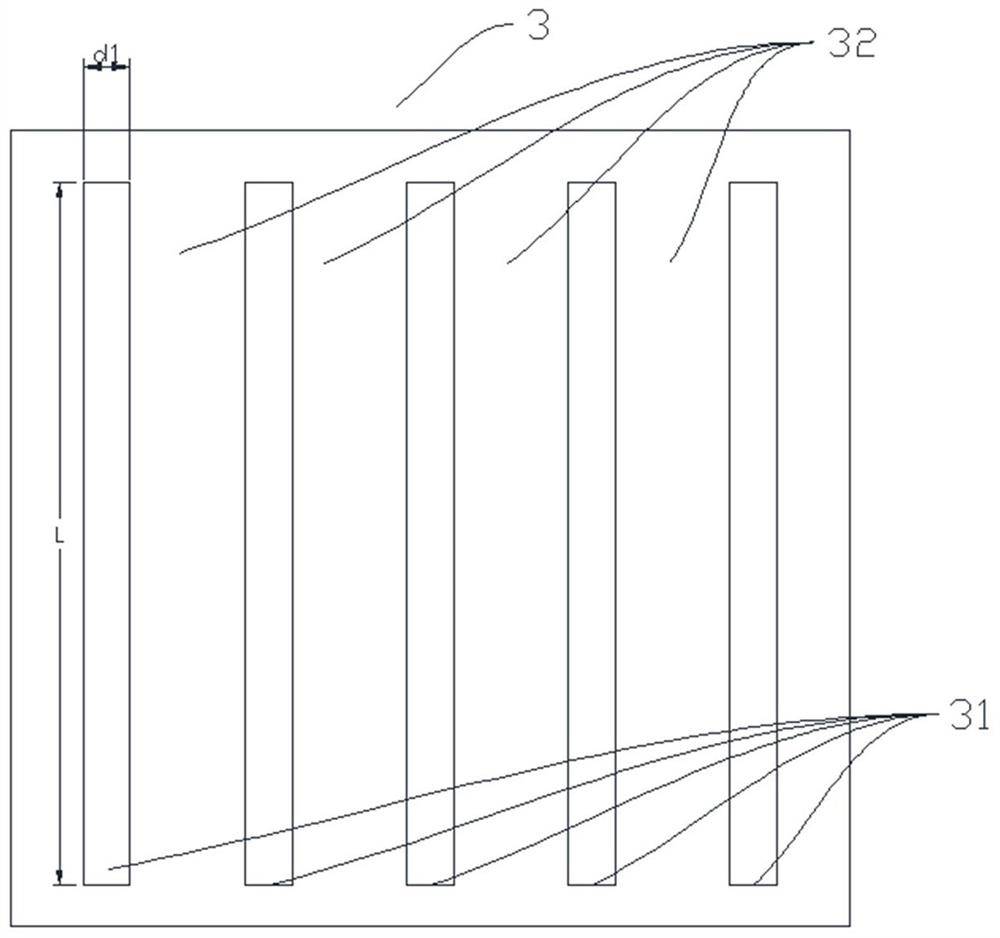

[0061] a lens array, arranged on the light propagation path, for focusing the light in the Y-axis direction, the lens array includes a plurality of lens units, and each lens unit corresponds t...

Embodiment 2

[0085] The difference between this embodiment and the first embodiment is that, as shown in the appendix Figure 7 As shown, a first optical element 7 is added in the light propagation path. The first optical element 7 is located between the lens array and the grating shaping array 3, and is used to collimate the light in the X-axis direction. The first optical element 7 can be A single cylindrical lens, or a group of cylindrical lenses, or a DOE (diffractive optical element).

[0086] In this embodiment, the light-emitting units 11 in the light-emitting unit array 1 are one or more point light sources or line light sources along the X-axis direction.

[0087] In order to ensure that the projected pattern on the working surface is in the shape of a grating strip, the length of the collimated beam should be greater than the length L of the light-transmitting area 31 in the grating shaping array 3 . When the light-emitting unit is a point light source, the focal length f of the...

Embodiment 3

[0091] The difference between this embodiment and the first embodiment is that, as shown in the appendix Figure 8 As shown, a second optical element 8 is added in the light propagation path. The second optical element 8 is located between the lens array and the grating shaping array 3 to change the divergence angle of the light in the X-axis direction, thereby controlling the working surface 6 The length of the projected pattern on the X axis. The second optical element 8 may be a single cylindrical lens, or a group of cylindrical lenses, or a DOE (Diffractive Optical Element).

[0092] Since the second optical element is added to constrain the divergence angle of light in the X-axis direction, the projection lens 5 in this embodiment can be composed of a cylindrical mirror, and only focuses the light beam passing through the grating shaping array 3 in the Y-axis direction, so that the The resulting grating strips are focused on the working surface 6 without changing the pro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com