Method of controlling resolution in inkjet printing

An inkjet printing, high-resolution technology, applied in the field of the film itself, can solve problems such as increasing the price of the film

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0052] Films for inkjet printing were produced containing the substances described in Table 1 below:

[0053] components

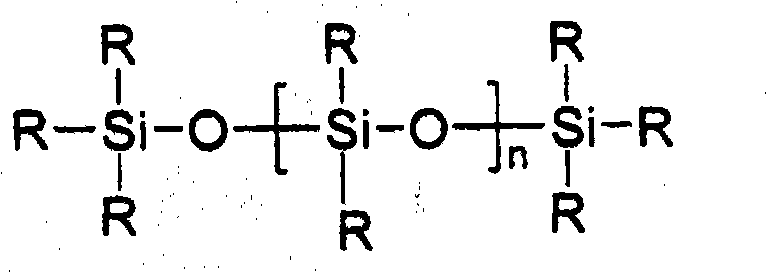

[0054] blue pigment violetmanganese VM 40

[0055] TiO 2 is a coated filler with a particle size of 250 μm and 0.5% by weight of polydimethylsiloxane coating. In some films, polydimethylsiloxane with a molecular weight of 8000 g / mol was added.

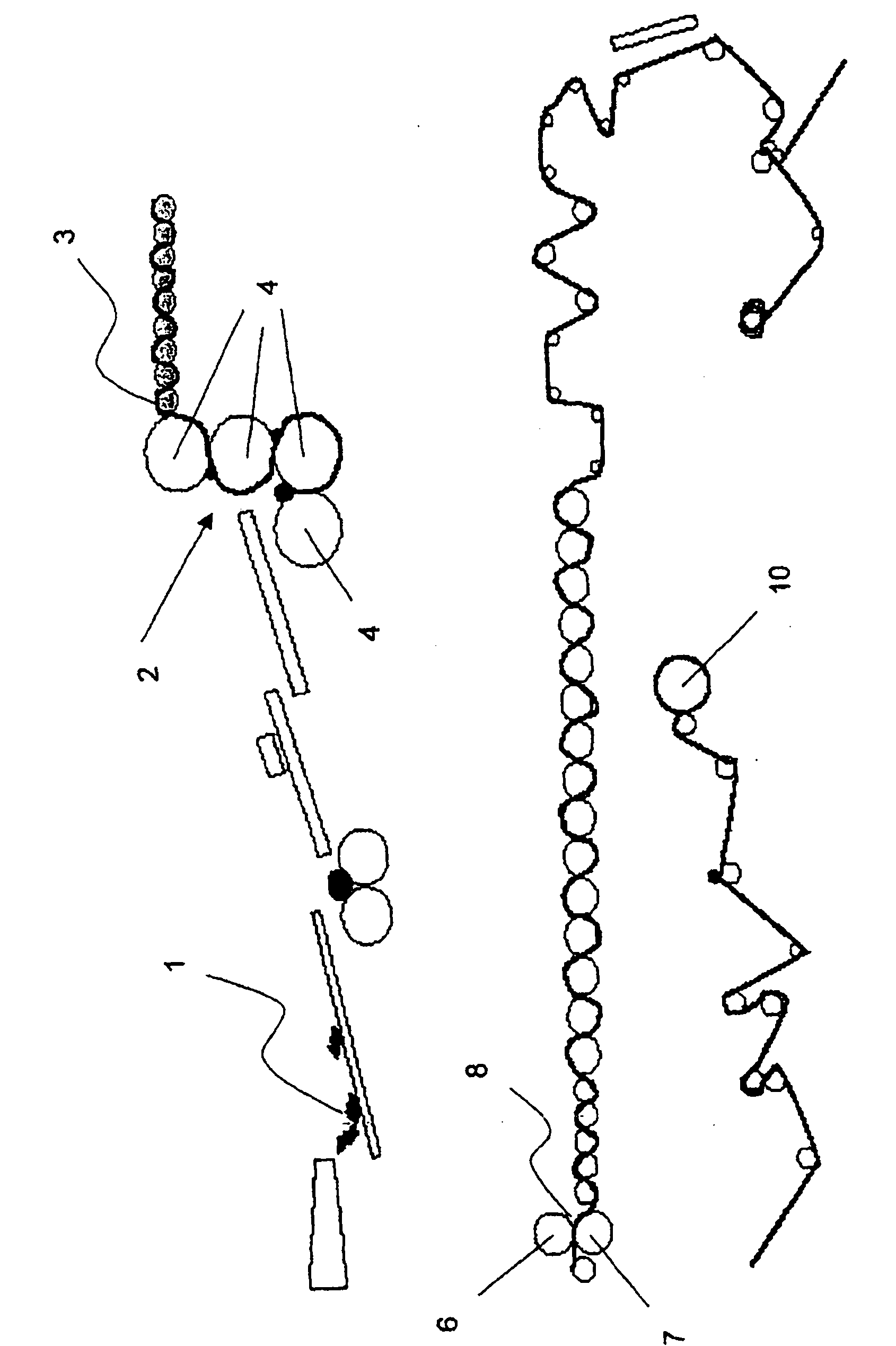

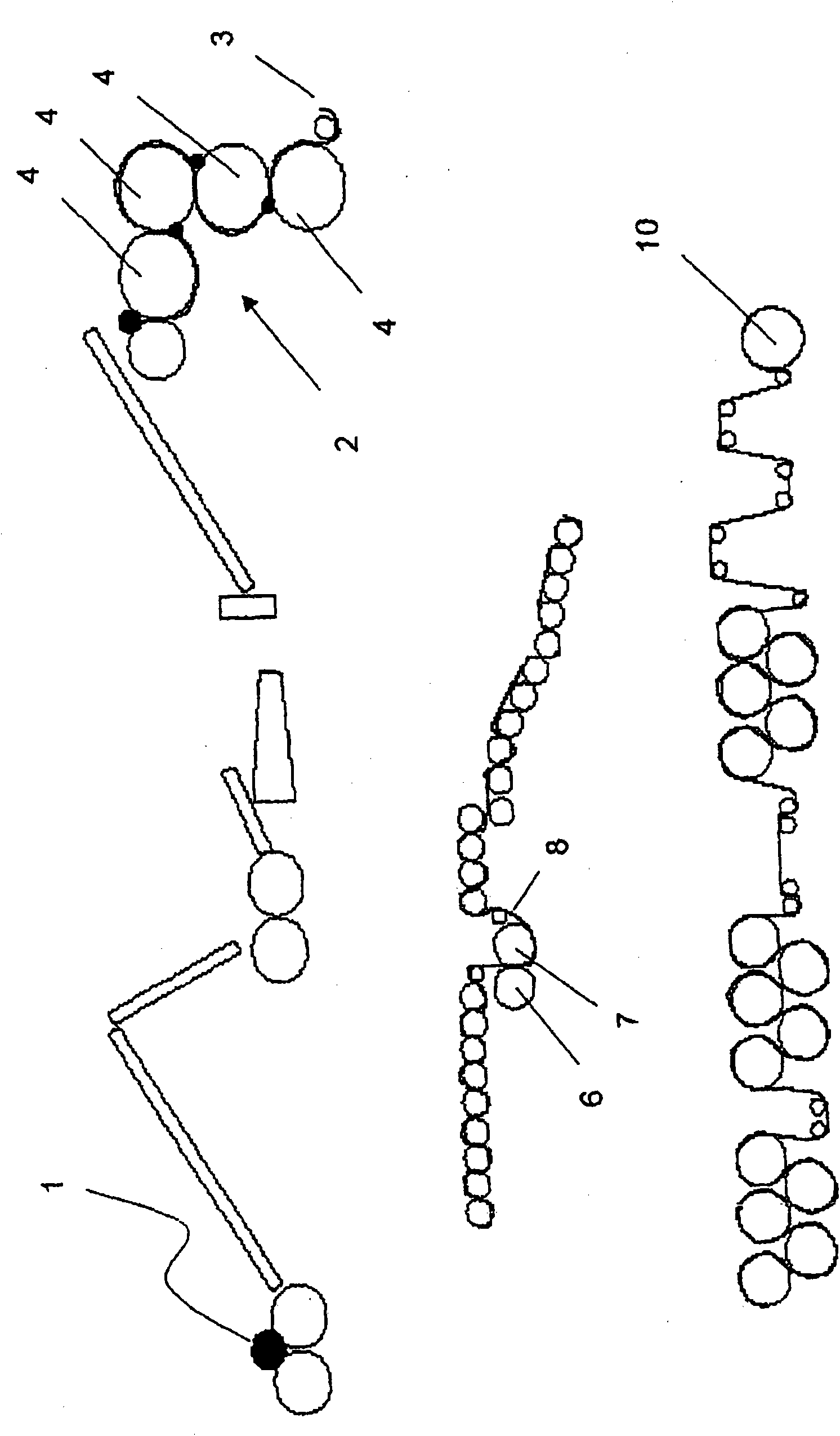

[0056] The components of the formulation were mixed together in a compound mixer with the temperature raised to 50°C with friction. The mixture was fed into extrusion equipment at about 160°C and the plasticized mass was conveyed to a roll mill at 160°C. A strip is taken from the homogeneous composition and fed into the nip of a calender with the following roll temperatures: Roll 1 = 165°C, Roll 2 = 166°C, Roll 3 = 211 °C, roll 4 = 169 °C. The primary film passes through a stripper roller at 172°C and then through an embossing unit at a selected temperature to provide the desired film surfac...

Embodiment 2

[0065] Films were further prepared from the compositions described in Table 4.

[0066] components

[0067] Using Coated and Uncoated TiO 2 .

[0068] Films were prepared by mixing the formulation components. In a first step the mixture is plasticized on a laboratory roll mill (2 rolls) at about 180-185° C. with low roll speed until rough sheets appear on the rolls. The film was homogenized by increasing the roll speed to 12 m / min with varying roll friction. After about 12 minutes, the film can be removed from the front roll and pulled over at a speed of 6 m / min by a conveyor belt of suitable thickness. The films were then thermally laminated on a laboratory press to obtain a flat surface for inkjet printability testing.

[0069] Resolution during inkjet printing was determined as described above. The results are listed in Table 5.

[0070] membrane

[0071] It can be seen that the resolution is improved by the coating as well as by the addition of po...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com