Sewage contamination vacuum exhaust and separation device

A technology for separating device and dirt, applied in the field of sewage suction vehicles, can solve the problems of complex overall structure and high use cost, and achieve the effects of simple structure, ensuring continuity of use, and controlling the degree of separation of dirt

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

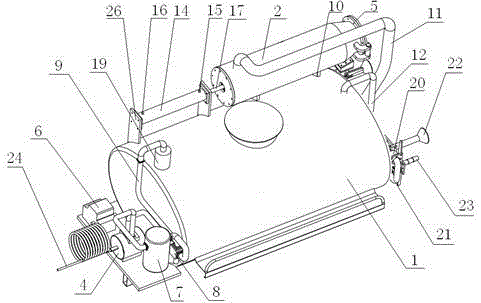

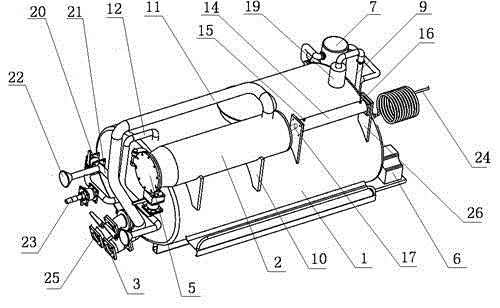

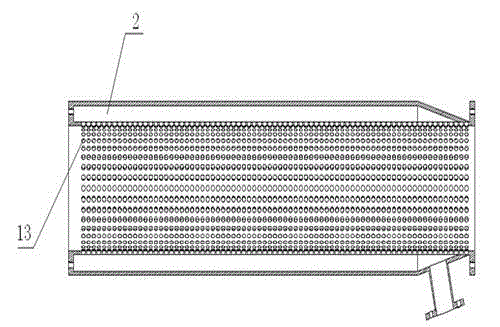

[0026] see Figure 1 to Figure 4 , a vacuum pumping and separating device for sewage and dirt, comprising a main tank body 1, a solid-liquid separation tank 2, a sewage suction port 3, and a vacuum pump 4, the vacuum pump 4 is located at the tail of the main tank body 1, and the sewage suction port 3 is located at the main tank At the bottom of the front end of the body 1, there is a sealing cover 5 at the front end of the solid-liquid separation tank 2. The vacuum pump 4 is connected with the power machine 6, the oil-gas separator 7, and the four-way valve 8 to provide positive and negative pressure for the main tank body 1. The four-way valve 8 is connected to the main tank body 1 through the vacuum pipeline 9, the solid-liquid separation tank 2 is placed horizontally on the top side of the main tank body 1 through the bracket 10, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com