Electronic equipment assembling device and electronic equipment assembling method

A technology for electronic equipment and assembly devices, which is applied in the connection/disconnection of connection devices, circuits, connections, etc., and can solve problems such as the lack of improvement in operating efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] Hereinafter, preferred embodiments of the present invention will be described in detail with reference to the drawings. Dimensions, materials, other specific numerical values, and the like shown in this embodiment are merely illustrations for making the invention easier to understand, and do not limit the present invention unless otherwise specified. In this specification and the drawings, elements having substantially the same functions and structures are assigned the same reference numerals to omit repeated descriptions, and elements not directly related to the present invention are omitted from illustration.

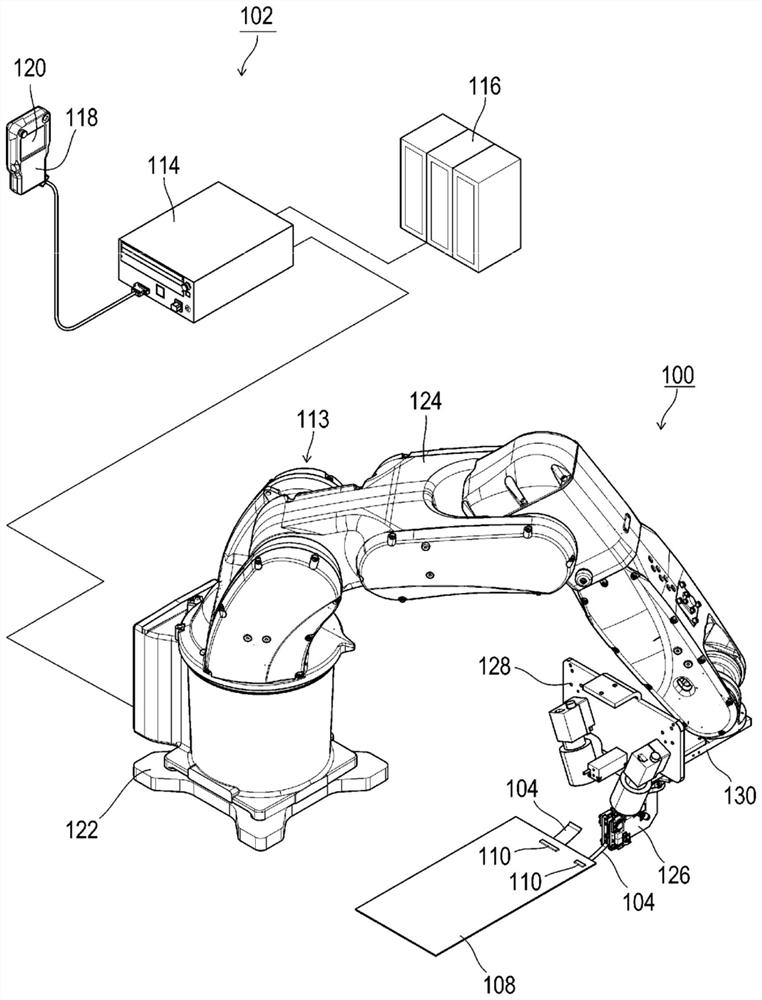

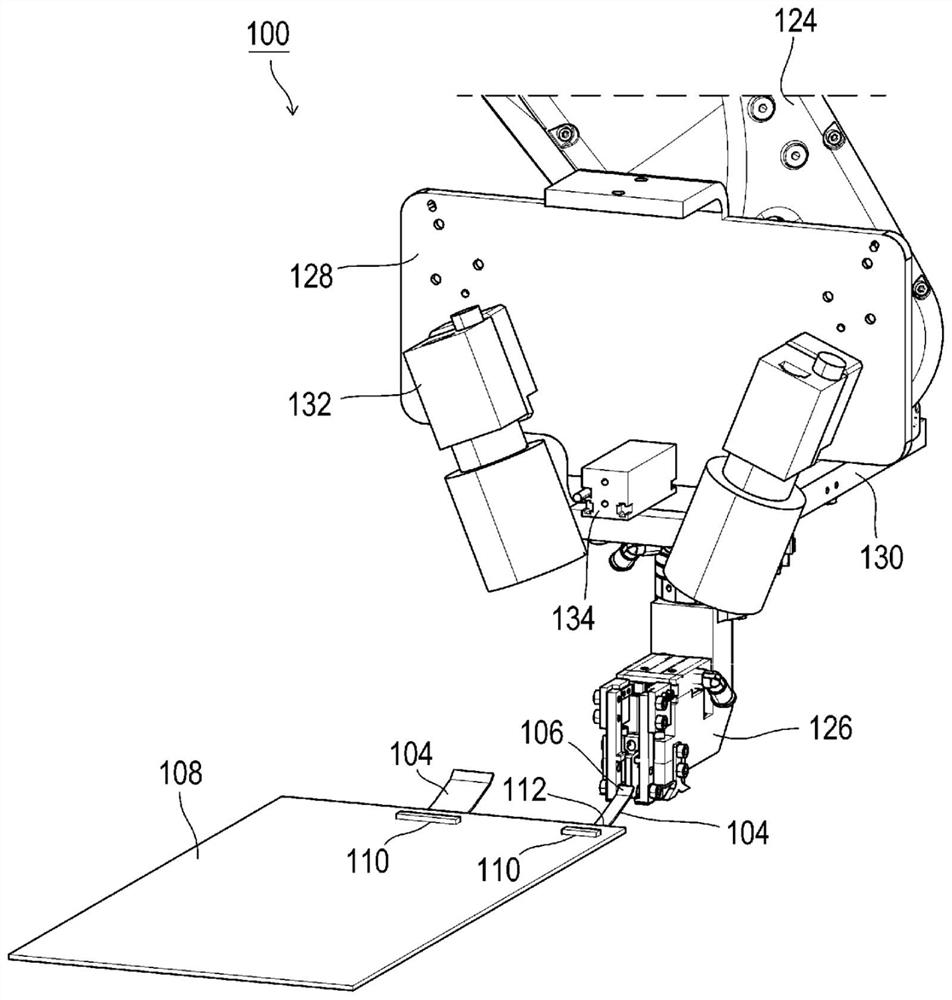

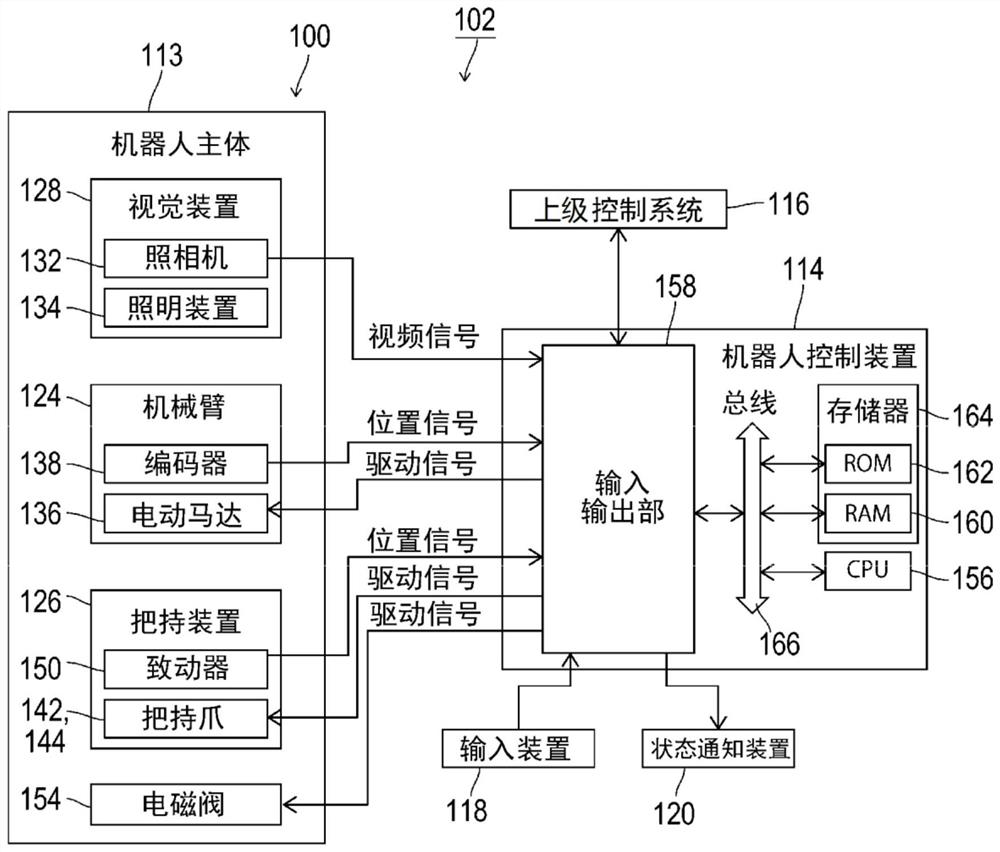

[0036] figure 1 It is an overall configuration diagram of the robot system 102 to which the electronic device assembling apparatus 100 according to the embodiment of the present invention is applied. figure 2 yes means figure 1 A partial view of the electronic device assembling apparatus 100 of . The electronic equipment assembly device 100 is, for exampl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com