Semi-automatic sealing system for flexible container

A flexible container, semi-automatic technology for climate sustainability, packaging sealing/fastening, bio-packaging, etc., which can solve problems such as increased production and maintenance costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

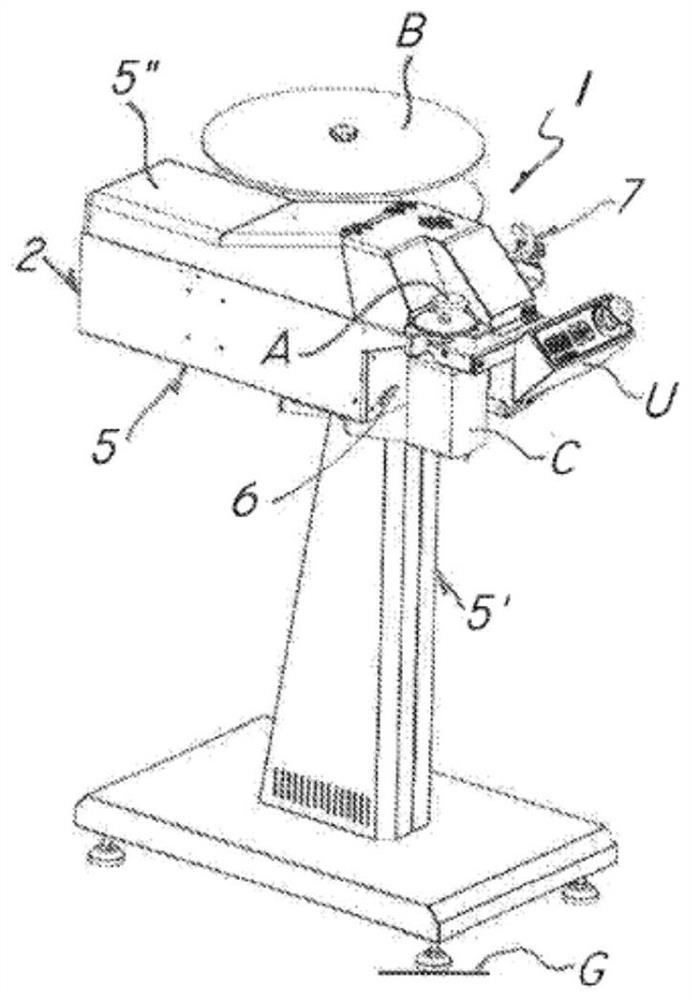

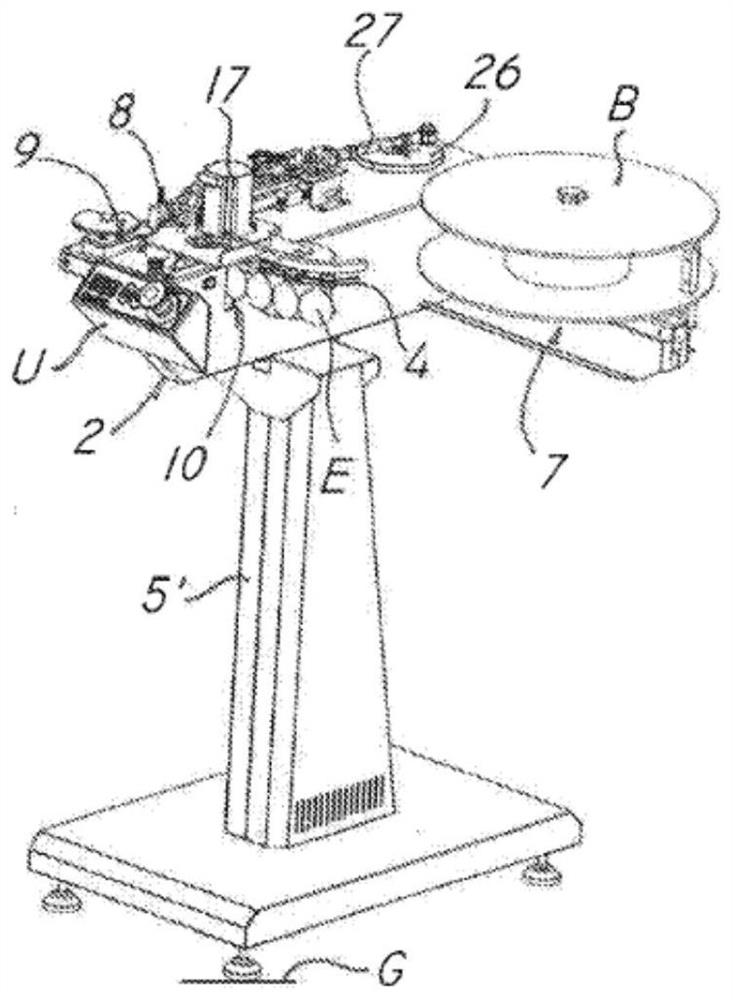

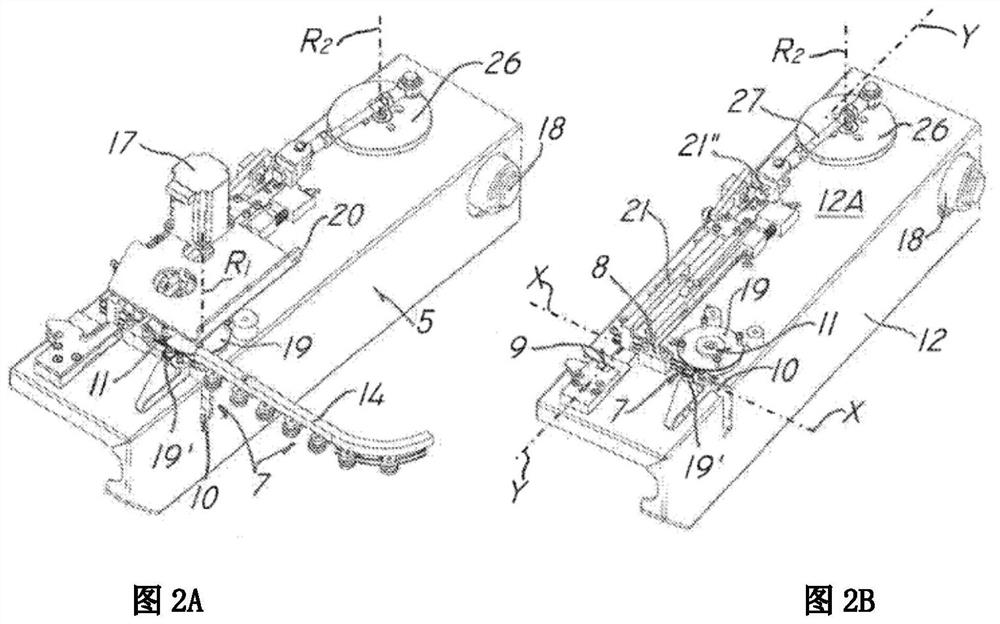

[0048] Referring to the accompanying drawings, there is shown a semi-automatic closing system for flexible containers, generally designated as reference numeral 1, for closing a container C, wherein the container C has an open end A through which the product contained therein can be removed .

[0049] In a non-limiting example, the container C can be made of flexible material such as paper, plastic and / or degradable material, and can hold any kind of product, including food, without specific limitation.

[0050] The system 1 comprises a reel B for receiving the winding of a deformable roll film N, the reel B having a strip 4 made of a semi-rigid deformable material, the upper edge 4A and the lower edge 4B of the strip 4 facing respectively Opening A and bottom B of container C.

[0051] As is well known, the strip 4 may be substantially flat, made of metal such as aluminum or of paper or polymeric material, the strip 4 includes a wire-like core 4C made of metal or non-metalli...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com