Low-dielectric bismaleimide resin system and preparation method of low-dielectric bismaleimide resin system

A technology of bismaleimide resin and bismaleimide, applied in the field of low-dielectric bismaleimide resin system and its preparation, low-dielectric high-performance resin-based composite materials, can solve the problem of thermosetting Poor dielectric properties of the resin system, reduced resin system crosslinking density, strength, heat resistance, low moisture absorption, etc., to achieve excellent mechanical properties and thermal properties, good mechanical properties, and low dielectric properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

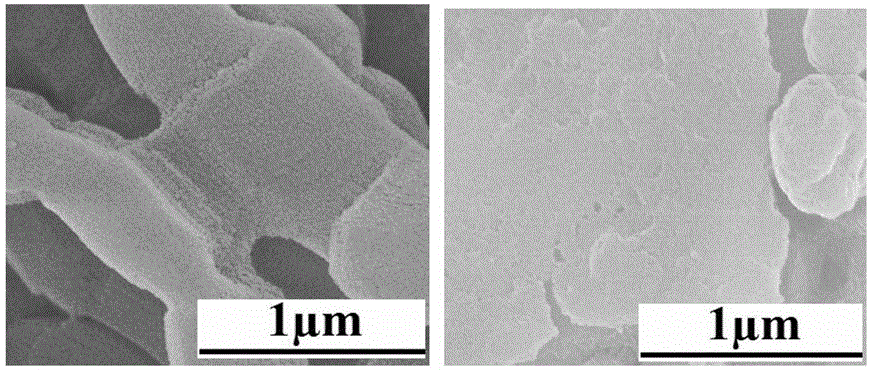

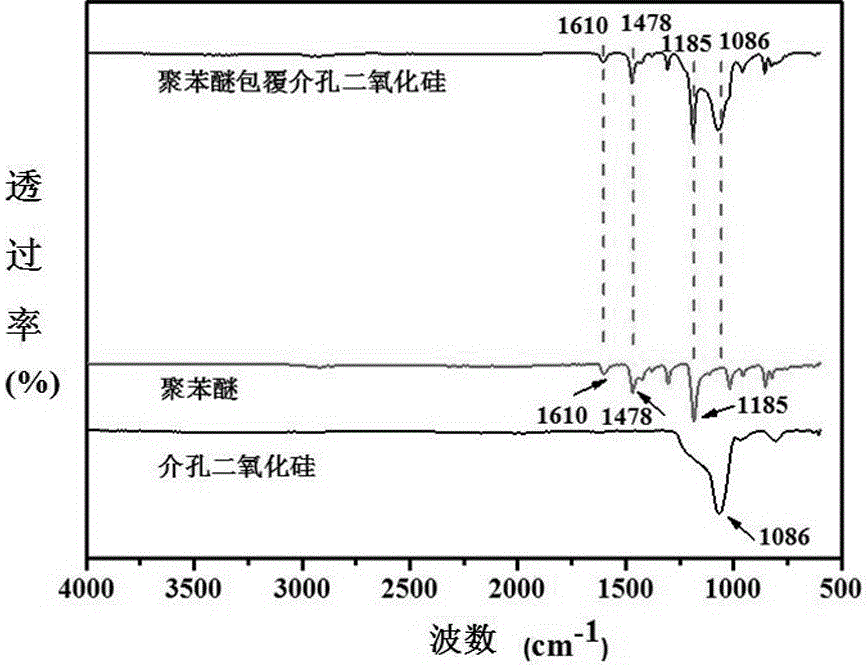

[0028] Completely dissolve 2g of polyphenylene ether (vinyl-terminated polyphenylene ether with a number average molecular weight of 1100 (PPO* MX9000-111)) in 25ml of toluene to obtain a polyphenylene ether solution, and then add 0.6g of mesoporous silica (UC-S-1), after stirring and dispersing, add it to 500ml aqueous solution of sodium lauryl sulfate surfactant with a mass concentration of 0.15% to form an oil-in-water system. Since polyphenylene ether is insoluble in water, with the gradual volatilization of toluene solvent, the precipitated polyphenylene ether will be deposited or adsorbed on the surface of mesoporous silica to seal the mesoporous pores. After stirring for 4 hours, the precipitate was washed, suction filtered, and vacuum-dried at 120°C for 4 hours to obtain a polyphenylene ether-filled and coated mesoporous silica material, wherein the mass ratio of polyphenylene ether to mesoporous silica raw material was 3.3: 1. figure 1 Scanning electron microscope (S...

Embodiment 2

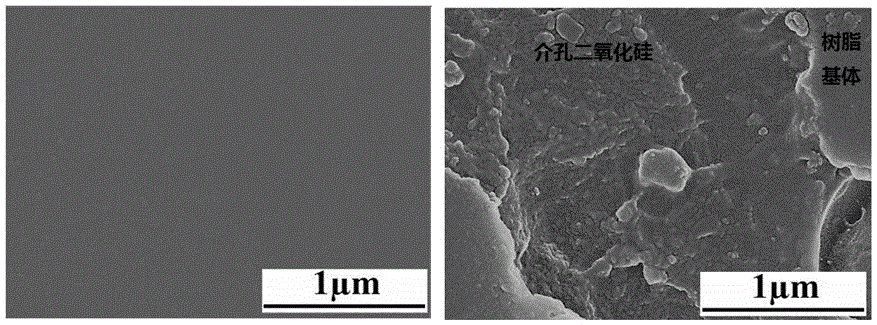

[0036] Completely dissolve 2g of polyphenylene ether (vinyl-terminated polyphenylene ether with a number average molecular weight of 1100 (PPO* MX9000-111)) in 25ml of toluene to obtain a polyphenylene ether solution, and then add 1.0g of mesoporous silica (UC-S-1), after stirring and dispersing, add it to 500ml aqueous solution of sodium lauryl sulfate surfactant with a mass concentration of 0.2%, to form an oil-in-water system. Since polyphenylene ether is insoluble in water, with the gradual volatilization of toluene solvent, the precipitated polyphenylene ether will be deposited or adsorbed on the surface of mesoporous silica to seal the mesoporous pores. After stirring for 5 hours, the precipitate was washed, filtered, and vacuum-dried at 120°C for 5 hours to obtain a polyphenylene ether-filled and coated mesoporous silica material, wherein the mass fraction ratio of polyphenylene ether to mesoporous silica raw material was 2 :1. Figure 4 SEM photo of mesoporous silica ...

Embodiment 3

[0044] 2g of polyphenylene ether (Noryl* SA9000 with a number average molecular weight of 2200) was completely dissolved in 30ml of toluene to obtain a polyphenylene ether solution, and then 1.4g of mesoporous silica (UC- S-3), after stirring and dispersing, add to 500ml aqueous solution of potassium monododecyl phosphate surfactant with a mass concentration of 0.3%, to form an oil-in-water system. Since polyphenylene ether is insoluble in water, with the gradual volatilization of toluene solvent, the precipitated polyphenylene ether will be deposited or adsorbed on the surface of mesoporous silica to fill or seal the mesoporous pores. After stirring for 6 hours, the precipitate was washed, filtered, and vacuum-dried at 120°C for 6 hours to obtain a polyphenylene ether-filled and coated mesoporous silica material, wherein the mass fraction ratio of polyphenylene ether to mesoporous silica raw material was 1.43 :1.

[0045] Stir and heat 50g of bismaleimide diphenyl ether and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com